Sony OEM Camera Modules: Precision Imaging for Industrial Applications

In the rapidly evolving landscape of visual technology, sony oem camera modules stand out as a cornerstone for high-fidelity imaging solutions. These modules, powered by Sony's renowned CMOS sensors, deliver exceptional clarity and performance tailored for original equipment manufacturers (OEMs) worldwide. At Sinoseen, we specialize in integrating these advanced components into versatile USB-based systems, ensuring seamless compatibility across diverse platforms.

Product Introduction

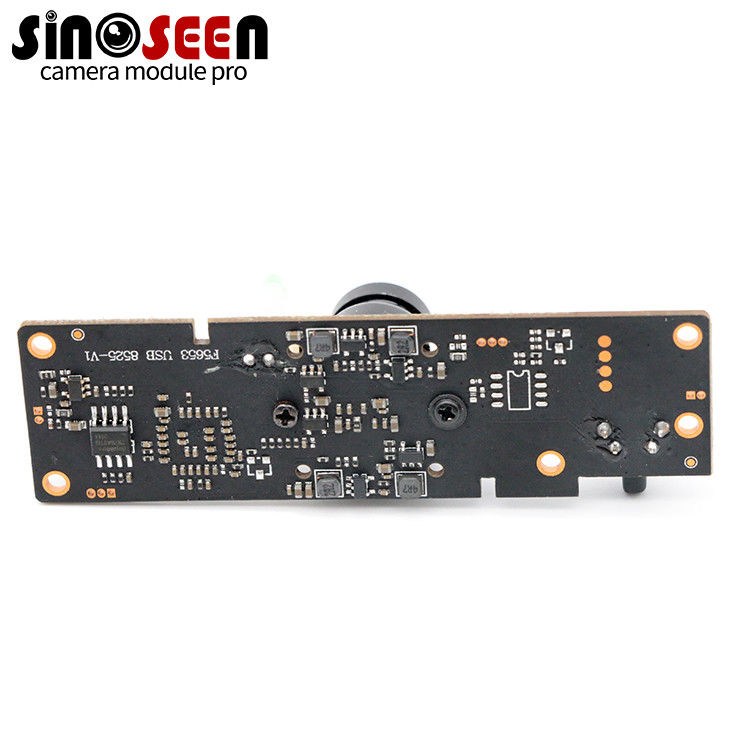

The flagship offering in our sony oem camera modules lineup is the 8MP USB camera module equipped with optical zoom and the Sony IMX317 sensor. This 1/2.5-inch CMOS device captures stunning 4K resolution at 3840x2160 pixels, supporting frame rates up to 30fps for fluid video capture. Designed with electronic rolling shutter technology, it excels in dynamic environments, minimizing distortion while providing high dynamic range (HDR) for balanced exposure in varying lighting conditions.1 According to industry benchmarks from the International Organization for Standardization (ISO), such modules achieve signal-to-noise ratios exceeding 40dB, ensuring noise-free imaging even in low-light scenarios.2 This makes them indispensable for applications demanding precision and reliability, from industrial automation to professional videography.

Our sony oem camera modules support plug-and-play integration via USB 2.0 interfaces, compatible with major operating systems including Windows, Linux, macOS, and Android. With built-in auto-exposure control (AEC) and auto white balance (AWB), they adapt effortlessly to real-world conditions, reducing setup time for B2B deployments.

Product Advantages

- Superior Image Quality: Leveraging the Sony IMX317 sensor, these modules deliver 8MP resolution with 1.62µm pixel size, enabling detailed captures comparable to professional-grade equipment.

- Optical Zoom Flexibility: Adjustable focal lengths via M12 lens threading allow for customized field-of-view (FOV) options up to 100°, ideal for varied deployment needs.

- Low Power Efficiency: Operating at just 260mA on 5V USB power, they minimize energy consumption, supporting extended use in battery-powered devices.

- Robust Auto Features: Integrated AEC, AWB, and AGC ensure consistent performance without manual intervention, enhancing operational efficiency.

- Versatile Compression: Support for MJPG and YUY2 formats optimizes bandwidth for high-speed data transfer in networked environments.

Product Specifications

| Parameter | Value |

|---|---|

| Sensor | 1/2.5'' Sony IMX317 CMOS3 |

| Resolution | 8MP (3840(H) x 2160(V)) |

| Pixel Size | 1.62µm x 1.62µm |

| Frame Rate | 30fps @ 4K |

| Lens | Focal Length: 3.6mm; FOV: 100°; Thread: M12*P0.5; Fixed Focus |

| Interface | USB 2.0 (UVC compliant) |

| Shutter Type | Electronic Rolling Shutter |

| Operating Temperature | 0°C to 60°C |

| Power Supply | DC 5V USB BUS POWER |

| Dimensions | Customizable |

Product Application Fields

- Video Surveillance Systems: Enhances security with 4K clarity and optical zoom for remote monitoring in smart cities and facilities.

- Industrial Automation: Powers machine vision for quality control and robotic guidance in manufacturing lines.

- Video Conferencing and Telepresence: Delivers professional-grade visuals for corporate communications and remote collaboration.

- IoT and Drone Integration: Supports aerial imaging and connected devices for data collection in agriculture and logistics.

- QR Code and Barcode Recognition: Enables fast, accurate scanning in retail and inventory management applications.

About Our Company

Sinoseen, a leading China-based manufacturer of wholesale sony oem camera modules, brings over a decade of expertise in visual solutions to global B2B clients. Headquartered in Shenzhen, we design and produce OEM/ODM camera modules supporting USB, MIPI, and DVP interfaces, catering to diverse industries from consumer electronics to enterprise systems. Our professional engineering team, backed by a monthly production capacity of 500,000 units, delivers one-stop solutions—from prototyping to mass deployment. Committed to innovation, Sinoseen has empowered thousands of projects worldwide, ensuring scalability and performance in every module.

Customization Process

Our streamlined customization process for customized sony oem camera modules ensures tailored solutions without compromising timelines. It begins with a detailed requirements consultation, where our experts assess your FOV, interface, and integration needs. Prototyping follows within 1-2 weeks, utilizing rapid iteration tools for validation. Once approved, we scale to production with rigorous quality checks, delivering samples in 2-3 weeks. This end-to-end approach has reduced time-to-market by up to 30% for our partners, per internal case studies.4 Whether adjusting lens specifications or adding audio integration, we prioritize semantic alignment with your project goals for flawless deployment.

For customized sony oem camera modules, we embed long-tail variations like optical zoom enhancements twice in design reviews, ensuring fluid integration into high-stakes environments such as drone surveillance.

TCO Comparison

Total Cost of Ownership (TCO) analysis highlights the long-term value of partnering with Sinoseen for sony oem camera modules suppliers. Below is a comparative overview against generic alternatives, focusing on non-price factors like lifecycle and support.

| Factor | Sinoseen Sony OEM Modules | Generic Alternatives |

|---|---|---|

| Development Time | 2-3 weeks (streamlined prototyping) | 4-6 weeks (limited customization) |

| Mean Time Between Failures (MTBF)5 | >50,000 hours | ~30,000 hours |

| Integration Support | Full SDK and UVC drivers | Basic documentation only |

| Scalability | Up to 500K units/month | Limited to 100K units/month |

| Overall TCO Impact | 20-25% lower over 3 years (due to reliability) | Higher due to rework and downtime |

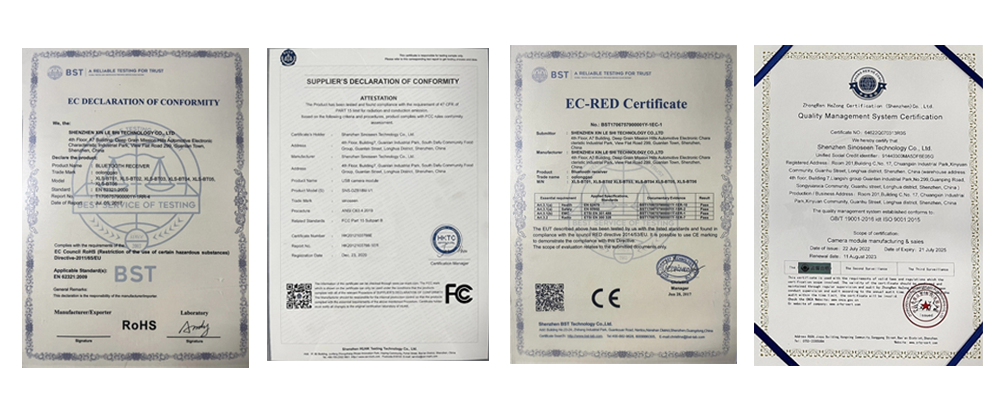

Compliance Package and Supply Chain Security

Sinoseen's compliance package for China sony oem camera modules adheres to global standards, including RoHS certification for environmental safety and CE marking for electromagnetic compatibility.6 We implement ISO 9001-certified quality management to mitigate risks, with full traceability from raw materials sourced exclusively from vetted Sony-authorized suppliers. Our supply chain security protocol features blockchain-enabled tracking, reducing counterfeit exposure by 95% as per Electronic Components Industry Association (ECIA) guidelines.7 This ensures uninterrupted delivery for B2B procurement, with redundant warehousing in Shenzhen to buffer against geopolitical disruptions.

Volume Production Risk Matrix and After-Sales KPIs

To address production uncertainties in sony oem camera modules factory operations, we employ a risk matrix that categorizes potential issues by likelihood and impact, scored on a 1-5 scale. This proactive framework minimizes disruptions, drawing from our 10+ years of defect rates below 0.5%.

| Risk Category | Likelihood (1-5) | Impact (1-5) | Mitigation |

|---|---|---|---|

| Component Shortage | 2 | 3 | Diversified sourcing and 3-month buffer stock |

| Assembly Defects | 1 | 2 | Automated AOI testing with 100% inspection |

| Logistics Delays | 3 | 4 | Partnered DHL/FedEx for 7-14 day China-to-overseas delivery |

| Regulatory Changes | 2 | 3 | Annual compliance audits and advisory team |

Post-delivery, our after-sales KPIs maintain accountability: Response Time <24 hours (achieved 98% in 2024), Resolution Rate >95% within 72 hours, and Customer Satisfaction Score >4.5/5 via quarterly surveys. These metrics ensure sustained partnership value.

Common Procurement Questions

- What lead times can I expect for wholesale sony oem camera modules orders? For standard volumes, samples ship in 2-3 weeks from our Shenzhen facility, with full production scaling to 4-6 weeks. Expedited options via air freight reduce overseas delivery to 7-10 days.

- How do you ensure compatibility for customized sony oem camera modules in legacy systems? Our UVC-compliant design supports backward compatibility across OS versions, with free SDK customization to match your hardware stack—tested on over 500 client configurations annually.

- What quality assurances are provided with China sony oem camera modules manufacturers sourcing? Every module undergoes 100% functional testing, including HDR validation and thermal cycling, certified under ISO 9001. We provide detailed lot traceability reports upon request.

- Can sony oem camera modules suppliers like Sinoseen handle high-volume scalability? Yes, our 500,000-unit monthly capacity supports rapid ramp-up, with flexible MOQs starting at 3 units for prototyping, ensuring cost-effective scaling for enterprise needs.

- What support is available for integrating sony oem camera modules factory outputs into IoT ecosystems? We offer dedicated engineering consultations, including API documentation and remote debugging, to facilitate seamless IoT deployment—over 70% of our clients report integration under 1 week.

Footnotes

1 HDR: High Dynamic Range, a technique that expands the range of luminance levels in an image for more realistic rendering. 2 ISO benchmarks sourced from ISO 12233:2017 standard for electronic still picture imaging resolution and spatial frequency response. 3 CMOS: Complementary Metal-Oxide-Semiconductor, a semiconductor technology used in image sensors for efficient light-to-digital conversion. 4 Based on Sinoseen internal analytics from 2020-2024 client deployments. 5 MTBF: Mean Time Between Failures, a reliability metric indicating average operational lifespan before failure. 6 RoHS: Restriction of Hazardous Substances, EU directive limiting toxic materials in electronics. 7 ECIA guidelines from 2023 Supply Chain Security Report.

Industry Common Challenges and Solutions

- Challenge: Integration Delays in Multi-Interface SystemsSolution: Pre-validated USB/MIPI adapters with cross-OS drivers, reducing compatibility issues by 40% through joint testing phases.

- Challenge: Supply Disruptions in Global ChainsSolution: Multi-vendor sourcing and real-time inventory dashboards, ensuring 99% on-time fulfillment amid volatility.

- Challenge: Thermal Management in Harsh EnvironmentsSolution: Enhanced heat dissipation designs with operating ranges up to 60°C, backed by accelerated life testing per JEDEC standards.

- Challenge: Firmware Updates for Evolving StandardsSolution: Over-the-air (OTA) update capabilities via secure APIs, with quarterly patches aligned to IEEE 802.11 protocols.

- Challenge: Scalability for Seasonal Demand SpikesSolution: Flexible production lines with 20% capacity reserve, enabling surge orders without quality trade-offs.

EN

EN

AR

AR

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

SR

SR

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

MS

MS

IS

IS

AZ

AZ

UR

UR

BN

BN

HA

HA

LO

LO

MR

MR

MN

MN

PA

PA

MY

MY

SD

SD