Custom Micro Camera Module Solutions for Medical and Wearable Technology.

The integration of advanced imaging technology into medical devices and wearable technology has revolutionized healthcare monitoring and diagnostic capabilities. Modern micro camera module solutions enable unprecedented miniaturization while maintaining exceptional image quality, making them essential components in next-generation medical instruments and consumer health devices. These compact imaging systems combine cutting-edge sensor technology with sophisticated optical design to deliver professional-grade performance in applications where space constraints and power efficiency are critical factors.

Advanced Sensor Technology in Medical Imaging Applications

High-Resolution CMOS Sensors for Diagnostic Excellence

The foundation of any effective micro camera module lies in its sensor technology, with advanced CMOS sensors providing the cornerstone for medical-grade imaging performance. Modern medical applications demand exceptional image clarity and color accuracy to support accurate diagnosis and patient monitoring. These sensors incorporate advanced pixel architectures that maximize light sensitivity while minimizing noise, ensuring that even in challenging lighting conditions, medical professionals receive clear, detailed images for clinical evaluation.

Contemporary micro camera module designs leverage back-illuminated sensor technology to achieve superior low-light performance, which is particularly crucial in endoscopic applications and internal medical imaging. The enhanced quantum efficiency of these sensors allows medical devices to capture high-quality images with reduced illumination requirements, improving patient comfort while maintaining diagnostic accuracy. This technological advancement has enabled the development of smaller, more comfortable medical instruments that can access previously challenging anatomical locations.

Specialized Optical Components for Medical Environments

Medical-grade micro camera module systems require specialized optical components designed to withstand sterilization processes and maintain optical performance under demanding conditions. The lens assemblies in these modules utilize medical-grade materials that resist chemical degradation from sterilization agents while maintaining optical clarity over extended operational periods. Anti-reflective coatings and specialized glass formulations ensure consistent image quality throughout the device lifecycle.

The optical design of medical micro camera module systems also incorporates advanced distortion correction and color management features. These capabilities are essential for applications requiring precise measurements or accurate color representation of tissue and biological samples. The integration of computational photography techniques within the module firmware enables real-time image enhancement and correction, providing medical professionals with optimized imagery for diagnostic purposes.

Wearable Technology Integration and Miniaturization

Power-Efficient Design for Extended Operation

Wearable devices incorporating micro camera module technology must balance imaging performance with power consumption to ensure all-day battery life. Modern module designs implement advanced power management systems that optimize energy usage through intelligent sleep modes and selective component activation. These power-saving features allow wearable devices to maintain continuous monitoring capabilities while preserving battery life for extended wear periods.

The development of ultra-low-power image signal processors specifically designed for wearable applications has significantly reduced the overall power consumption of micro camera module systems. These specialized processors can perform complex image processing tasks while consuming minimal power, enabling features such as continuous health monitoring, gesture recognition, and environmental sensing without compromising device battery life or user comfort.

Form Factor Optimization for Wearable Comfort

The physical design of micro camera module components for wearable applications requires careful consideration of size, weight, and ergonomic factors. Engineers must create modules that integrate seamlessly into wearable form factors while maintaining optimal optical performance. This involves innovative packaging techniques that minimize module thickness and weight while protecting sensitive optical components from environmental factors and physical stress.

Advanced materials science plays a crucial role in developing wearable-compatible micro camera module housings that resist moisture, temperature variations, and mechanical stress. These protective enclosures must maintain optical clarity while providing robust protection for internal components. The integration of flexible circuit technologies allows for creative mounting solutions that adapt to curved surfaces and dynamic movement patterns typical in wearable applications.

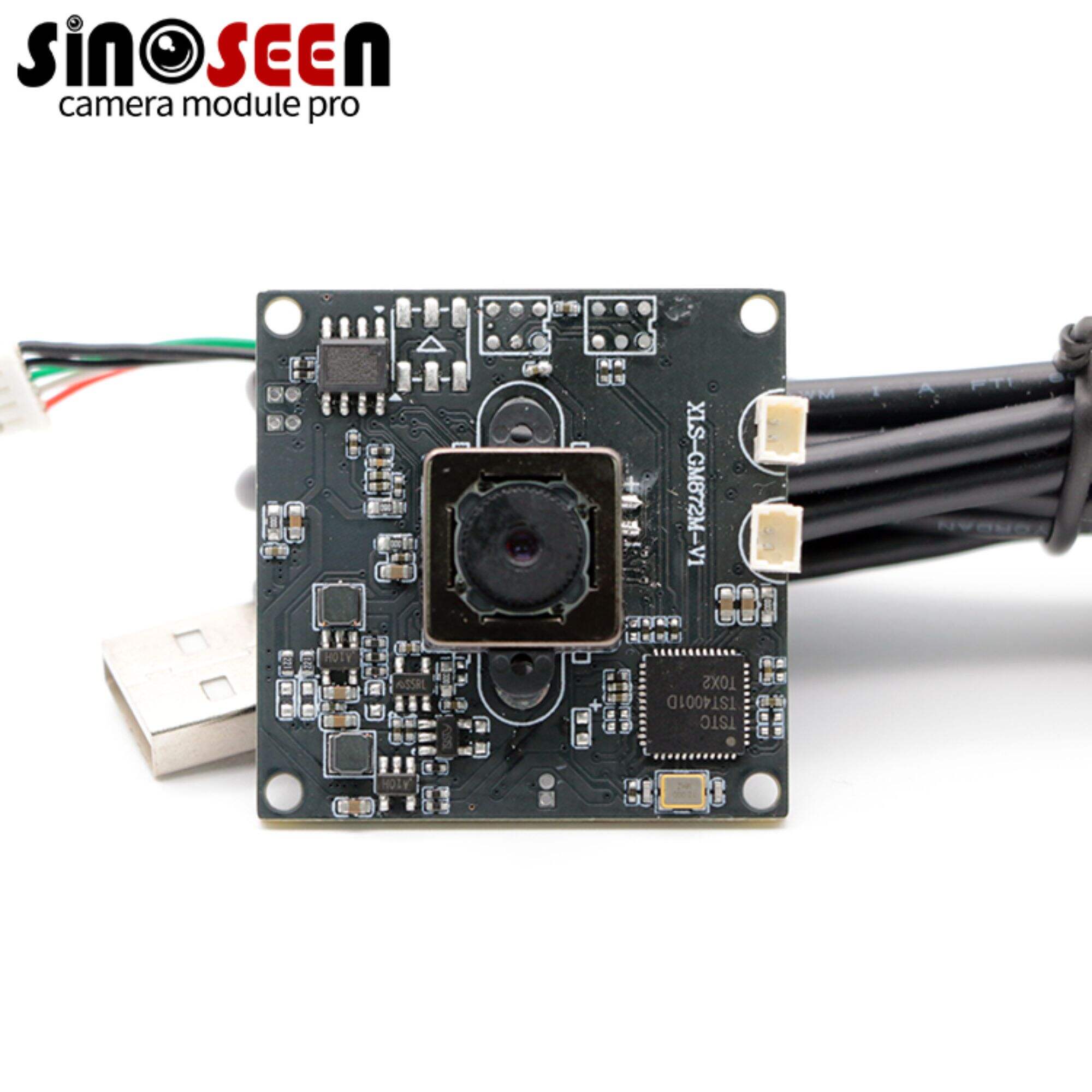

Dual-Lens Systems and 3D Imaging Capabilities

Stereoscopic Imaging for Depth Perception

Modern micro camera module solutions increasingly incorporate dual-lens configurations to enable three-dimensional imaging capabilities. These stereo vision systems provide depth information that enhances medical diagnostics and enables advanced wearable functionalities such as gesture recognition and spatial awareness. The precise calibration and synchronization of dual micro camera module systems require sophisticated algorithms and hardware coordination to ensure accurate depth measurements.

The implementation of stereoscopic imaging in compact form factors presents unique engineering challenges related to baseline distance and optical alignment. Designers must optimize the spacing between individual micro camera module components to maximize depth accuracy while maintaining the overall compactness required for medical and wearable applications. Advanced manufacturing techniques ensure precise alignment and consistent performance across production volumes.

Facial Recognition and Biometric Applications

The integration of facial recognition capabilities within micro camera module systems has opened new possibilities for secure medical device access and patient identification. These biometric systems utilize advanced machine learning algorithms running on embedded processors to provide rapid and accurate identification while maintaining patient privacy and data security. The compact nature of modern micro camera module designs enables seamless integration into existing medical equipment without significant form factor modifications.

Wearable devices incorporating facial recognition through micro camera module technology offer enhanced security features and personalized user experiences. These systems can adapt device settings based on user identification and provide secure access to sensitive health data. The continuous improvement in processing power and algorithm efficiency enables real-time facial recognition processing within the power constraints typical of wearable devices.

Manufacturing Excellence and Quality Assurance

Precision Assembly and Calibration Processes

The manufacturing of medical-grade micro camera module systems requires exceptional precision and rigorous quality control procedures. Each component undergoes extensive testing and calibration to ensure consistent performance across varying environmental conditions and operational scenarios. Automated assembly systems utilize computer vision and precision robotics to achieve the accuracy required for optimal optical alignment and performance consistency.

Quality assurance protocols for micro camera module production include comprehensive optical testing, environmental stress testing, and long-term reliability validation. These processes ensure that modules maintain their performance specifications throughout their intended operational lifetime, which is particularly critical for medical applications where device reliability directly impacts patient safety and diagnostic accuracy.

Regulatory Compliance and Medical Certification

Medical applications of micro camera module technology must comply with stringent regulatory requirements and industry standards. Manufacturers must demonstrate compliance with medical device regulations, biocompatibility requirements, and electromagnetic compatibility standards. The certification process involves extensive documentation, testing, and validation procedures that ensure patient safety and device efficacy in clinical environments.

The development of micro camera module systems for medical applications also requires adherence to specific imaging standards and performance criteria. These standards define minimum requirements for image quality, color accuracy, and system reliability that must be maintained throughout the device lifecycle. Compliance with international medical device standards facilitates global market access and ensures consistent quality across different regulatory jurisdictions.

Future Developments and Emerging Technologies

Artificial Intelligence Integration

The future of micro camera module technology lies in the integration of artificial intelligence capabilities directly within the imaging system. Edge AI processing enables real-time analysis of captured imagery, providing immediate insights for medical diagnosis and wearable device functionality. These intelligent micro camera module systems can identify anomalies, track health metrics, and provide decision support without requiring external processing resources.

Machine learning algorithms optimized for micro camera module applications continue to evolve, offering improved accuracy and reduced computational requirements. These advancements enable more sophisticated image analysis capabilities while maintaining the power efficiency and form factor constraints essential for medical and wearable applications. The integration of AI processing directly within micro camera module hardware represents a significant step toward autonomous medical monitoring and diagnostic systems.

Advanced Imaging Modalities

Emerging imaging technologies such as hyperspectral imaging and fluorescence microscopy are being adapted for micro camera module implementations. These advanced modalities provide additional diagnostic information beyond traditional visible light imaging, enabling new applications in medical diagnostics and biological research. The miniaturization of these sophisticated imaging techniques opens possibilities for point-of-care diagnostics and portable laboratory equipment.

The development of multi-spectral micro camera module systems enables simultaneous capture of different wavelength ranges, providing enhanced diagnostic capabilities for medical applications. These systems can identify tissue characteristics, monitor blood oxygenation, and detect pathological changes that are not visible in standard imaging modalities. The compact implementation of multi-spectral imaging technology represents a significant advancement in portable medical diagnostics.

FAQ

What are the key advantages of using micro camera modules in medical devices?

Micro camera modules offer several critical advantages for medical applications, including exceptional miniaturization capabilities that enable access to previously inaccessible anatomical locations, reduced patient discomfort during procedures, and improved diagnostic accuracy through high-resolution imaging. These compact systems also provide cost-effective solutions for medical device manufacturers while maintaining professional-grade image quality essential for clinical applications. Additionally, the low power consumption and robust design of modern micro camera modules make them ideal for portable and handheld medical devices.

How do dual-lens micro camera modules enhance wearable device functionality?

Dual-lens micro camera module configurations provide stereoscopic vision capabilities that enable depth perception and three-dimensional imaging in wearable devices. This technology supports advanced features such as gesture recognition, spatial awareness, and augmented reality applications while maintaining the compact form factor required for comfortable wearability. The dual-lens setup also enables improved facial recognition accuracy and enhanced security features for personal health data protection in wearable medical monitoring devices.

What quality standards must micro camera modules meet for medical applications?

Medical-grade micro camera modules must comply with strict regulatory standards including FDA approval for medical devices, ISO 13485 quality management systems, and IEC 60601 electrical safety requirements. These modules must also demonstrate biocompatibility according to ISO 10993 standards, electromagnetic compatibility compliance, and resistance to sterilization processes. Additionally, they must meet specific imaging performance criteria for color accuracy, resolution, and consistency to ensure reliable diagnostic capabilities in clinical environments.

How do manufacturers ensure consistent performance across micro camera module production?

Manufacturers implement comprehensive quality control systems including automated optical inspection, precision calibration procedures, and statistical process control monitoring throughout production. Each micro camera module undergoes individual testing for optical performance, electrical characteristics, and environmental resistance before final approval. Advanced manufacturing techniques utilize computer vision systems and precision robotics to ensure consistent assembly quality, while comprehensive traceability systems enable continuous monitoring of component and process variations that could affect final product performance.

EN

EN

AR

AR

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

SR

SR

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

MS

MS

IS

IS

AZ

AZ

UR

UR

BN

BN

HA

HA

LO

LO

MR

MR

MN

MN

PA

PA

MY

MY

SD

SD