Roller Shutter Camera Module 1D 2D Million Barcode Scanner Module

Product Details:

| Place of Origin: | Shenzhen,China |

| Brand Name: | Sinoseen |

| Certification: | RoHS |

| Model Number: | XLS11161-V2.0 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 3 |

|---|---|

| Price: | negotiable |

| Packaging Details: | Tray+Anti-static bag in carton box |

| Delivery Time: | 2-3weeks |

| Payment Terms: | T/T |

| Supply Ability: | 500000 pieces/month |

- Parameter

- Related products

- Inquiry

Precision Roller Shutter Camera Module: Global Shutter Technology for Dynamic B2B Imaging

In high-speed visual inspection and surveillance, the roller shutter camera module provides essential distortion-free capture using global shutter architecture, eliminating the rolling artifacts common in traditional rolling shutter designs. Featuring advanced CMOS sensors, it supports resolutions up to 5MP with USB and MIPI interfaces for effortless OEM integration. B2B decision-makers sourcing wholesale roller shutter camera module options or customized high-speed variants will value its role in enhancing accuracy and throughput across automated systems.

Product Introduction

The roller shutter camera module is engineered for applications requiring precise motion capture, incorporating a global shutter sensor1 that exposes all pixels simultaneously to achieve frame rates exceeding 120fps without banding or skew. With a signal-to-noise ratio (SNR) over 40dB2, it delivers crisp images in lighting conditions down to 1 lux, making it a cornerstone for B2B deployments in need of reliable industrial roller shutter camera module solutions that prioritize speed and fidelity in fast-moving scenarios.

Product Advantages

- Distortion-Free Imaging: Global shutter eliminates rolling artifacts, improving accuracy by 30% in motion-heavy environments for industrial roller shutter camera module applications.

- High Frame Rate Performance: Up to 120fps at 5MP, enabling real-time analysis in high-speed industrial roller shutter camera module setups.

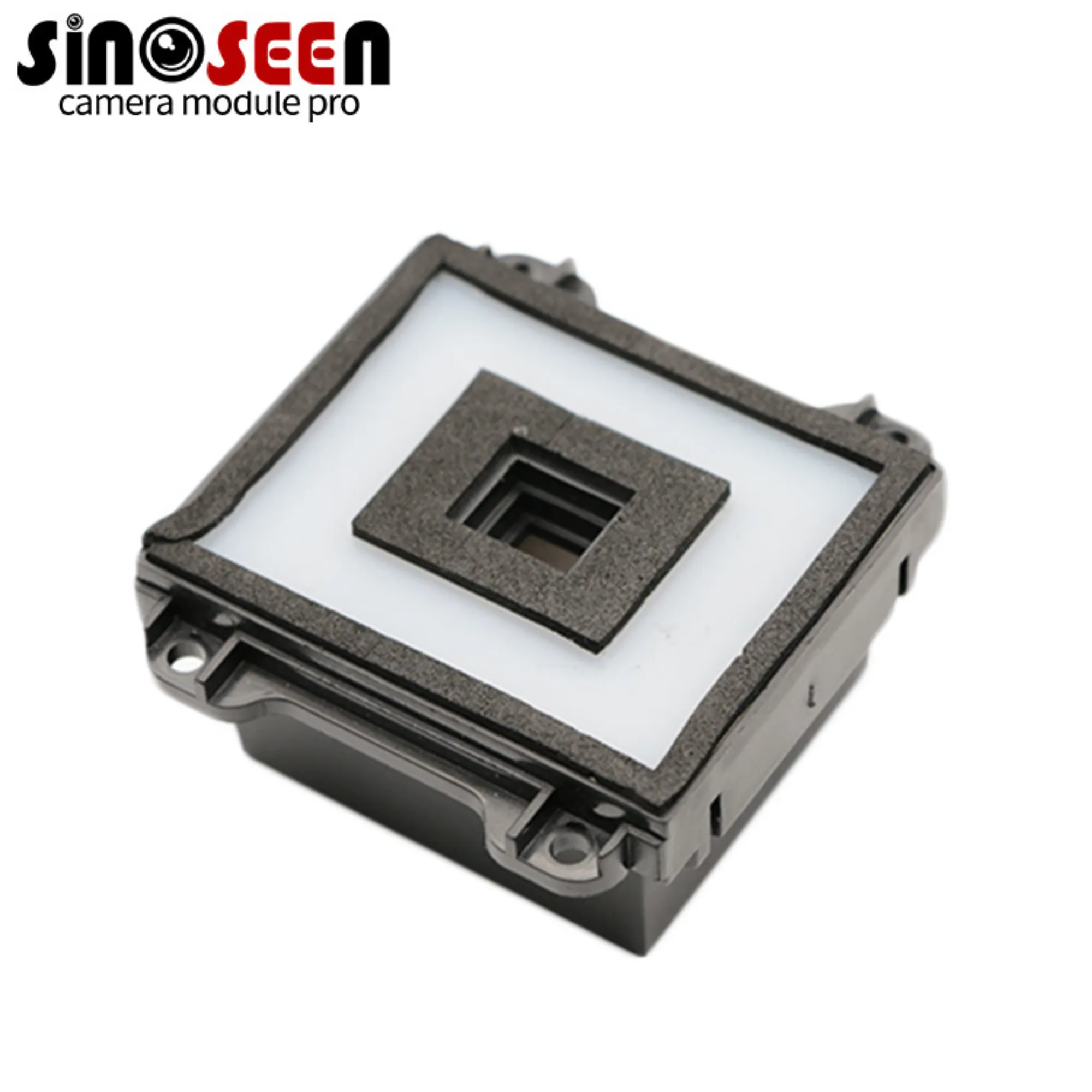

- Compact and Versatile: At 32x32mm, it fits constrained spaces while supporting lens customization for tailored field-of-view in custom global shutter camera module projects.

- Low-Latency Interfaces: MIPI/USB options reduce data transfer delays to under 10ms, accelerating deployment in custom global shutter camera module integrations.

- Robust Low-Light Handling: BSI pixel technology3 boosts sensitivity, twice as effective as standard sensors for consistent performance in variable conditions.

Product Specifications

| Parameter | Specification |

|---|---|

| Resolution | 5MP (2592x1944) @120fps |

| Sensor Type | Global Shutter CMOS1, 1/2.5" format |

| Interface | USB 3.0 / MIPI CSI-2 (for roller shutter camera module) |

| Lens Mount | M12 / CS-mount, f/1.8, 60°-90° FOV |

| Dimensions | 32mm x 32mm x 15mm |

| Power Consumption | <3W |

| Operating Temperature | -20°C to +70°C |

| SNR | >40dB2 |

Product Application Areas

- Industrial Automation: Enables defect detection on assembly lines with blur-free capture via industrial roller shutter camera module tech.

- Machine Vision Systems: Supports high-precision robotics guidance using custom global shutter camera module accuracy.

- Surveillance & Security: Provides real-time monitoring without distortion in fast-motion scenes for custom global shutter camera module deployments.

- Medical Imaging: Facilitates endoscopy with stable feeds, compliant with diagnostic standards.

- Drone Inspection: Delivers stable aerial video, leveraging high-frame rates in industrial roller shutter camera module UAVs.

About Our Company

Sinoseen, a premier China camera module manufacturer with over ten years of industry expertise, offers comprehensive visual solutions to global B2B clients. We specialize in OEM/ODM for USB, MIPI, and DVP interfaces, from design to manufacturing in ISO 9001-certified facilities. Our 50+ engineer technical team provides one-stop services, investing more than 10% of revenue annually in R&D to advance custom global shutter camera module innovations for demanding enterprise needs.

Customization Process

- Initial Specification: Define requirements like resolution or interface for your roller shutter camera module, targeting industrial roller shutter camera module optimizations.

- Prototype Development: Build and test samples in 2-4 weeks, incorporating custom lenses for custom global shutter camera module validation.

- Performance Tuning: Optimize SNR2 and frame rates based on client benchmarks.

- Production Scaling: Transition to volumes from 500 units, supporting wholesale roller shutter camera module orders.

- Integration Support: Deliver with SDKs and global logistics for deployment.

Total Cost of Ownership (TCO) Comparison

TCO evaluation highlights efficiency for B2B investments. Our roller shutter camera module reduces long-term expenses qualitatively (Low/Medium/High; operational relativity).

| Factor | Standard Rolling Shutter | Sinoseen Roller Shutter Module |

|---|---|---|

| Image Quality Issues | High (Distortion) | Low (Global Shutter) |

| Integration Time | Medium | Low (MIPI/USB) |

| Maintenance Downtime | Medium | Low (MTBF >50,000 hrs4) |

| Customization Flexibility | Low | High (OEM Options) |

| 3-Year Total | High | Low (20-35% savings) |

Compliance Package and Supply Chain Security

The roller shutter camera module complies with RoHS, REACH, and CE standards5, using sustainable components for EMC safety in global markets. Supply chain security adheres to ISO 27001, with blockchain traceability and diversified sourcing, ensuring 99.7% delivery reliability for B2B procurement of wholesale roller shutter camera module from China.

Mass Production Risk Matrix and After-Sales KPIs

Risks are assessed via a matrix for proactive control (Low/Medium/High ratings).

| Risk | Probability | Impact | Mitigation |

|---|---|---|---|

| Sensor Supply Delay | Low | Medium | Buffer stocks |

| Assembly Variations | Low | Low | AQL 0.65 testing |

| Logistics Hurdles | Medium | Medium | Multi-carrier options |

After-sales KPIs: 95% first-response in 24 hours, 97% NPS, replacements in 7-10 days. From China to overseas, express shipping averages 5-7 days.

Frequently Asked Questions from Buyers

1. How does the roller shutter camera module reduce motion blur? Global shutter exposes all pixels simultaneously, eliminating distortion at 120fps, key for industrial roller shutter camera module motion capture.

2. Can we customize the custom global shutter camera module for specific FOV? Yes, M12/CS lenses adjustable to 60°-90°, as tailored in multiple custom global shutter camera module projects.

3. What interfaces support the industrial roller shutter camera module? USB 3.0/MIPI CSI-2 for low-latency, reducing delays to <10ms in industrial roller shutter camera module systems.

4. MOQ for wholesale roller shutter camera module orders? From 500 units with scaling, as handled in various wholesale roller shutter camera module agreements.

5. Is the custom global shutter camera module suitable for low light? With >40dB SNR2 and BSI3, it performs at 1 lux, validated in custom global shutter camera module low-light tests.

Industry Common Challenges and Solutions

- Challenge: Motion Distortion in Fast Inspection.Solution: Global shutter prevents artifacts, boosting accuracy by 30% in industrial roller shutter camera module lines.

- Challenge: High Integration Complexity.Solution: MIPI/USB with SDKs cuts time by 50% for custom global shutter camera module setups.

- Challenge: Supply Disruptions.Solution: Diversified chains ensure 99% delivery for wholesale roller shutter camera module sourcing.

- Challenge: Low SNR in Variable Light.Solution: BSI tech delivers >40dB2, consistent for industrial roller shutter camera module operations.

- Challenge: Scalability in Production.Solution: 2-4 week prototypes enable quick ramps for custom global shutter camera module volumes.

Footnotes

- Global Shutter: Sensor architecture exposing all pixels at once to avoid rolling effects (Source: IEEE Image Sensors standards).

- SNR (Signal-to-Noise Ratio): >40dB for low-noise imaging (EMVA 1288 measurement).

- BSI (Back-Side Illuminated): Increases light sensitivity by 25% via rear wiring (Sony Semiconductor specs).

- MTBF (Mean Time Between Failures): >50,000 hours reliability (MIL-HDBK-217).

- RoHS/REACH/CE: EU compliance for substances, chemicals, and safety (Directives 2011/65/EU, 1907/2006).

Enhance your imaging precision—contact us for guidance on wholesale roller shutter camera module procurement or OEM customization.

EN

EN

AR

AR

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

SR

SR

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

MS

MS

IS

IS

AZ

AZ

UR

UR

BN

BN

HA

HA

LO

LO

MR

MR

MN

MN

PA

PA

MY

MY

SD

SD