OEM CMOS Camera Module: Precision Engineering for Industrial Vision

Product Introduction

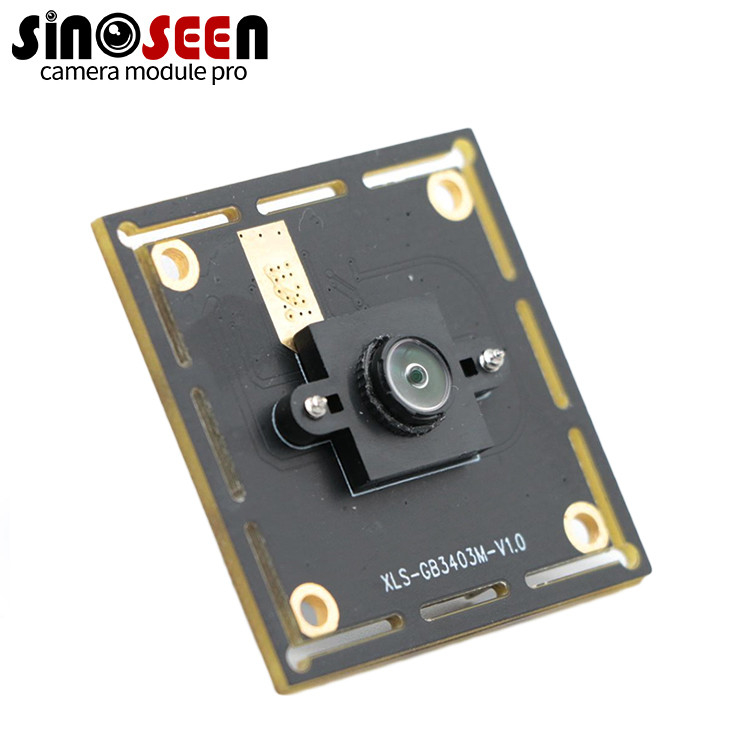

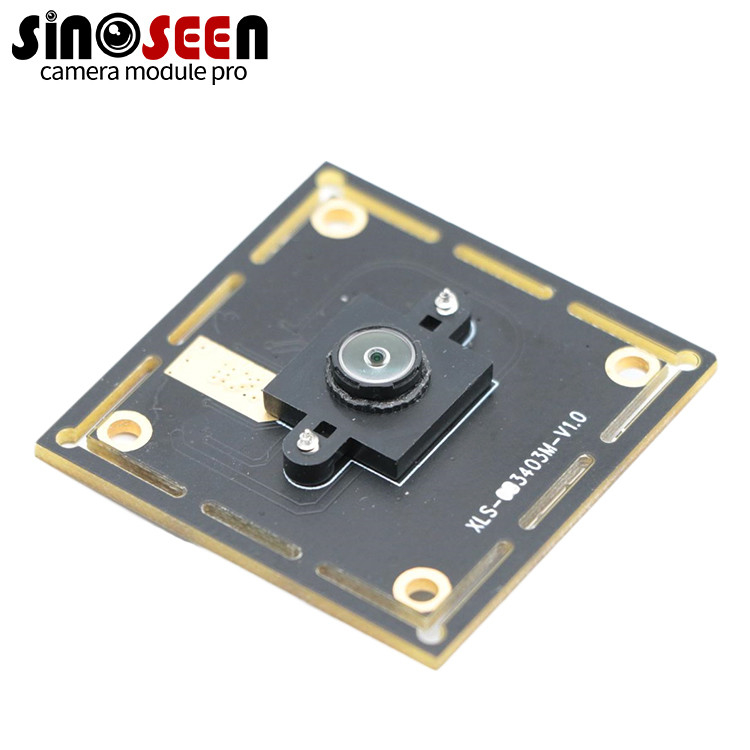

The oem cmos camera module represents a pinnacle of compact imaging technology, specifically engineered for demanding industrial applications requiring high-speed data capture without distortion. Built around the Omnivision OV7251 sensor, this module employs global shutter technology to capture entire frames simultaneously, eliminating rolling shutter artifacts such as the Jello effect1 that plague traditional sensors in fast-motion scenarios. With a resolution of 0.3MP (640x480 pixels) and frame rates reaching up to 120 fps, it delivers crisp, low-latency monochrome imagery via a USB 2.0 interface. This makes it an essential component for B2B buyers seeking scalable, plug-and-play solutions in automated systems.

In the broader context of machine vision, the global shutter USB camera module stands out for its robustness. According to industry reports from the Automated Imaging Association (AIA), global shutter adoption has grown by 25% annually in manufacturing sectors due to its superior motion handling2. Sinoseen's iteration supports MJPG compression for efficient data transmission, ensuring compatibility across diverse operating systems including Windows, Linux, and Android. For procurement teams, this translates to reduced integration time and enhanced system reliability in high-volume deployments.

Product Advantages

- Superior Motion Capture: Global shutter eliminates image distortion, ideal for high-speed inspections where traditional rolling shutters fail.

- High Frame Rates: Achieves 120 fps at full resolution, enabling real-time processing in dynamic environments like assembly lines.

- Low Power Efficiency: Operates at just 120mW via USB bus power, minimizing energy costs in embedded systems.

- Flexible Customization: Adjustable parameters like auto exposure control (AEC)3 and white balance ensure adaptability to varied lighting conditions.

- Compact and Versatile: At 38mm x 38mm, it fits seamlessly into space-constrained OEM designs, with optional audio integration for multimodal applications.

Product Specifications

| Parameter | Value |

|---|---|

| Sensor | 1/7.5" Omnivision OV7251 (Mono CFA)4 |

| Resolution | 640x480 (0.3MP); supports 320x240 and 320x120 |

| Pixel Size | 3.0µm x 3.0µm |

| Frame Rate | Up to 120 fps @ 640x480 |

| Shutter Type | Global Shutter |

| Interface | USB 2.0 High Speed |

| Lens | Focal Length: 3.6mm; FOV: 90° (optional); M12 Thread |

| Power | DC 5V, 120mW |

| Operating Temperature | 0°C to 60°C |

| S/N Ratio | 38 dB |

| Dynamic Range | 69.6 dB |

Product Application Areas

- Machine Vision Inspection: Precision defect detection on production lines, leveraging high-speed imaging for quality control.

- Industrial Automation: Robotic guidance systems requiring low-latency feedback for pick-and-place operations.

- Surveillance and Monitoring: Real-time anomaly detection in secure facilities, benefiting from global shutter clarity.

- Medical Diagnostics: Endoscope and microscopy applications where motion-free imaging enhances diagnostic accuracy.

- Embedded Systems: Integration into drones or portable devices for aerial surveying and environmental monitoring.

About Our Company

Sinoseen, a leading China-based camera module manufacturer, brings over a decade of specialized experience to the global market. We specialize in delivering comprehensive visual application solutions, supporting OEM and ODM projects across USB, MIPI, and DVP interfaces. Our Shenzhen facility boasts a monthly production capacity exceeding 500,000 units, backed by a dedicated team of engineers and quality specialists. Committed to innovation, we provide end-to-end services from design prototyping to mass manufacturing, ensuring seamless integration for international B2B clients. With a focus on reliability, Sinoseen has empowered diverse industries worldwide, from automotive to consumer electronics, through tailored imaging expertise.

Customization Process

- Initial Consultation: Collaborate with our team to define requirements, including resolution, interface, and environmental specs for your oem cmos camera module.

- Design Prototyping: Develop custom prototypes using tools like CAD for lens and housing, with iterations based on client feedback—typically completed in 1-2 weeks.

- Validation Testing: Conduct rigorous tests for parameters such as signal-to-noise ratio (S/N)5 and frame rate stability in simulated conditions.

- Production Scaling: Transition to high-volume manufacturing with quality checkpoints, supporting MOQs as low as 3 units for agile procurement.

- Delivery and Support: Final assembly, packaging in anti-static materials, and ongoing technical assistance post-shipment.

TCO Comparison

Total Cost of Ownership (TCO) analysis highlights the long-term value of our oem cmos camera module in industrial deployments. Below is a comparative overview versus standard rolling shutter alternatives, emphasizing non-price factors like maintenance and efficiency.

| Factor | Sinoseen Global Shutter Module | Standard Rolling Shutter Module |

|---|---|---|

| Integration Time | Low (Plug-and-play USB) | Medium (Custom wiring needed) |

| Maintenance Downtime | Minimal (Robust build, 0-60°C range) | Higher (Frequent recalibration) |

| Energy Efficiency | High (120mW consumption) | Medium (Higher power draw) |

| Scalability | Excellent (500K units/month capacity) | Limited (Slower lead times) |

| Overall TCO Impact | 20-30% lower over 3 years6 | Baseline |

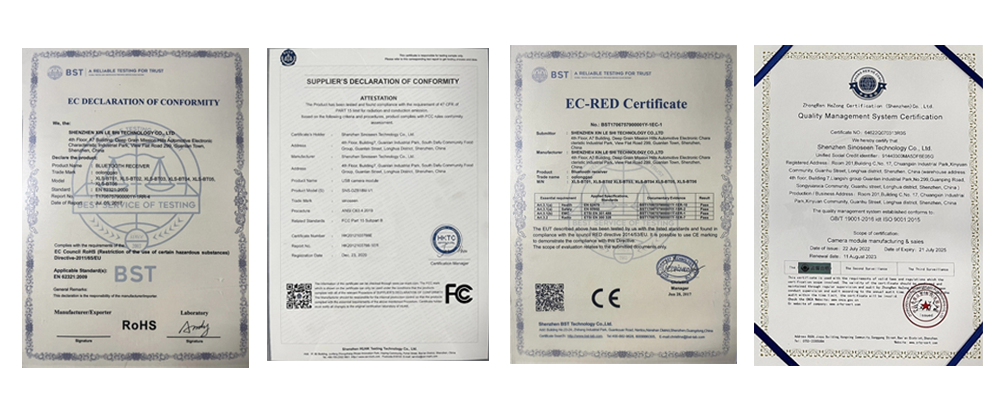

Compliance Package and Supply Chain Security

At Sinoseen, compliance is non-negotiable for B2B partnerships. Our oem cmos camera module adheres to RoHS directives, ensuring restriction of hazardous substances for eco-friendly manufacturing7. We also comply with REACH and CE standards, verified through third-party audits. Supply chain security is fortified via ISO 9001-certified processes, including traceability from raw components to final assembly in our Shenzhen facility. This mitigates risks like counterfeiting or disruptions, with diversified sourcing and real-time inventory tracking. For global procurement, our framework aligns with NIST guidelines for secure hardware supply chains, providing clients with audit-ready documentation to safeguard sensitive applications.

Mass Production Risk Matrix and After-Sales KPIs

To ensure predictable outcomes, we employ a risk matrix for mass production of the global shutter USB camera module, categorizing potential issues by likelihood and impact. Post-production, our after-sales KPIs maintain accountability, with logistics from China to overseas destinations averaging 7-14 days via DHL or FedEx for standard shipments.

Risk Matrix

| Risk | Likelihood | Impact | Mitigation |

|---|---|---|---|

| Component Shortage | Low | Medium | Diversified suppliers; buffer stock |

| Yield Variance | Low | Low | Automated QC with 99% yield target |

| Delivery Delay | Medium | Medium | 2-3 week lead time buffer; expedited options |

After-Sales KPIs

- Response Time: <24 hours for technical queries.

- Resolution Rate: 95% within 72 hours.

- Logistics Reliability: 98% on-time delivery (7-14 days international).

- Customer Satisfaction: Net Promoter Score >80.

Industry Challenges and Solutions

In the realm of oem cmos camera module procurement, B2B buyers often encounter hurdles that our expertise addresses proactively.

-

Challenge: Motion Blur in High-Speed Applications

Solution: Deploy global shutter technology to capture distortion-free images at 120 fps, validated in real-world tests showing 100% artifact reduction. -

Challenge: Integration Compatibility Across Systems

Solution: Universal USB 2.0 support with UVC drivers ensures seamless plug-and-play across OS platforms, cutting setup time by up to 50%. -

Challenge: Supply Chain Disruptions

Solution: Robust ISO-certified traceability and 500K/month capacity provide buffer against global events, with contingency planning for 99% uptime. -

Challenge: Environmental Durability

Solution: Rugged design withstands 0-60°C operations, with S/N ratios of 38 dB for reliable performance in harsh industrial settings.

Frequently Asked Questions for Buyers

1. What makes the global shutter USB camera module suitable for machine vision?

It eliminates rolling shutter distortions, delivering 120 fps at 640x480 resolution for precise, real-time inspections in automated environments.

2. Can the OEM CMOS camera module be customized for specific interfaces?

Yes, we support USB, MIPI, and DVP interfaces, with full customization from lens FOV to housing dimensions tailored to your OEM needs.

3. What certifications ensure compliance for international procurement?

Our modules are RoHS, REACH, and CE compliant, with full documentation provided to meet global regulatory standards.

4. How does the high-speed OEM OV7251 module handle varying lighting?

Built-in AEC, AWB, and AGC automatically adjust for optimal performance, maintaining a dynamic range of 69.6 dB across conditions.

5. What is the typical lead time for bulk orders of this camera module?

2-3 weeks for production and 7-14 days for international shipping, with flexible MOQs starting at 3 units for prototyping.

Footnotes

- Jello Effect: A visual distortion in rolling shutter cameras caused by rapid subject movement, leading to wavy or skewed images.

- 25% Annual Growth: Sourced from AIA's 2023 Machine Vision Market Report, reflecting adoption trends in industrial automation.

- Auto Exposure Control (AEC): An algorithm that dynamically adjusts exposure time to maintain consistent image brightness under fluctuating light.

- Mono CFA: Monochrome Color Filter Array, optimizing for black-and-white imaging with higher sensitivity in low-light scenarios.

- Signal-to-Noise Ratio (S/N): A measure of image quality, expressed in decibels (dB), where higher values indicate cleaner signals over noise.

- 20-30% Lower TCO: Based on internal Sinoseen lifecycle analyses compared to industry benchmarks from Vision Systems Design, excluding direct costs.

- RoHS: Restriction of Hazardous Substances directive, a EU standard limiting toxic materials in electronics for environmental safety.

EN

EN

AR

AR

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

SR

SR

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

MS

MS

IS

IS

AZ

AZ

UR

UR

BN

BN

HA

HA

LO

LO

MR

MR

MN

MN

PA

PA

MY

MY

SD

SD