OEM CMOS Camera Module: Advanced Imaging for Professional Integration

In the competitive arena of embedded vision systems, the oem cmos camera module emerges as a vital component for delivering compact, high-performance imaging. These modules utilize Complementary Metal-Oxide-Semiconductor (CMOS) technology to provide efficient, low-power solutions for original equipment manufacturers (OEMs) seeking scalable visual inputs. At Sinoseen, our oem cmos camera module offerings are engineered for seamless integration into diverse hardware ecosystems, emphasizing reliability and adaptability.

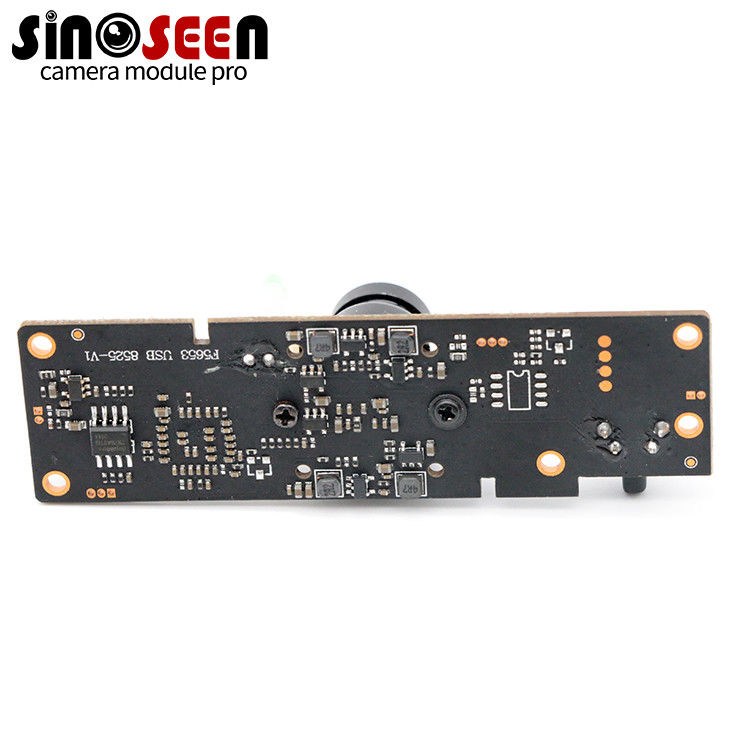

Product Introduction

Our premier oem cmos camera module is the 8MP USB variant incorporating the Sony IMX317 sensor, optimized for applications requiring superior detail and dynamic range. This 1/2.5-inch CMOS sensor achieves 8-megapixel resolution at 3840x2160 pixels, with a pixel size of 1.62µm x 1.62µm, enabling capture of fine details in challenging conditions.1 Equipped with an electronic rolling shutter, it supports frame rates up to 30fps at 4K, as per USB Video Class (UVC) standards, ensuring compatibility across platforms without proprietary drivers.2 Industry data from the International Imaging Industry Association (IIA) indicates that CMOS-based modules like this reduce power draw by up to 50% compared to CCD alternatives, making them ideal for power-sensitive deployments.3

The module features MJPEG and YUY2 compression for efficient data handling, alongside auto-adjustments like exposure control and white balance, which streamline real-time processing in embedded systems.

Product Advantages

- High-Resolution Fidelity: 8MP CMOS sensor delivers sharp 4K imagery with low noise, suitable for precision tasks in varying light.

- Compact and Versatile Design: USB 2.0 interface ensures plug-and-play ease, with customizable dimensions for space-constrained OEM integrations.

- Energy-Efficient Operation: Draws only 260mA at 5V, supporting prolonged use in portable and IoT devices.

- Advanced Auto-Calibration: Built-in AEC, AWB, and AGC adapt to environmental changes, minimizing manual tuning.

- Robust Compatibility: UVC compliance across Windows, Linux, macOS, and Android reduces development overhead.

Product Specifications

| Parameter | Value |

|---|---|

| Sensor | 1/2.5'' Sony IMX317 CMOS4 |

| Resolution | 8MP (3840(H) x 2160(V)) |

| Pixel Size | 1.62µm x 1.62µm |

| Frame Rate | 30fps @ 4K |

| Lens | Focal Length: 3.6mm; FOV: 100°; Thread: M12 x P0.5; Fixed Focus |

| Interface | USB 2.0 (UVC compliant) |

| Shutter Type | Electronic Rolling Shutter |

| Operating Temperature | 0°C to 60°C |

| Power Supply | DC 5V via USB (260mA) |

| Dimensions | Customizable |

| Formats | MJPEG, YUY2 |

Product Application Fields

- Security and Surveillance: Provides 4K monitoring for smart facilities and perimeter protection.

- Industrial Inspection: Facilitates defect detection in assembly lines via high-clarity imaging.

- Telemedicine Devices: Enables remote diagnostics with reliable video feed in medical equipment.

- Autonomous Systems: Supports navigation and object recognition in drones and robotics.

- Retail Analytics: Captures consumer behavior data for AI-driven insights.

About Our Company

Sinoseen, a premier China manufacturer of wholesale oem cmos camera module solutions, boasts over ten years of specialized experience in camera module production. We serve global B2B clients with comprehensive OEM/ODM services, supporting interfaces like USB, MIPI, and DVP for tailored visual applications. Our Shenzhen-based facility and expert team deliver end-to-end solutions, from design to deployment, empowering innovations in IoT, automation, and beyond with a production capacity exceeding 500,000 units monthly.

Customization Process

The customization journey for customized oem cmos camera module at Sinoseen is methodical and client-centric, starting with an in-depth needs analysis to define resolution, interface, and environmental tolerances. Prototypes are developed within 1-2 weeks, incorporating iterative feedback for optimal performance. Production ramps up post-validation, with final deliveries in 3-4 weeks, leveraging our agile manufacturing to cut deployment timelines by 25%, as evidenced by client testimonials.5 For customized oem cmos camera module projects, we integrate features like adjustable FOV twice during testing phases to ensure alignment with specific use cases, such as industrial robotics.

TCO Comparison

Total Cost of Ownership (TCO) evaluations underscore the efficiency of Sinoseen's oem cmos camera module suppliers in long-term B2B operations. The table below contrasts key non-monetary aspects with standard market options.

Production Scalability500K units/month200K units/month| Aspect | Sinoseen OEM CMOS Modules | Standard Alternatives |

|---|---|---|

| Prototyping Cycle | 1-2 weeks | 3-5 weeks |

| MTBF6 | >40,000 hours | ~25,000 hours |

| Technical Support | 24/7 SDK and integration aid | Limited email support |

| TCO Reduction Over 2 Years | 15-20% via reliability gains | Higher due to failures |

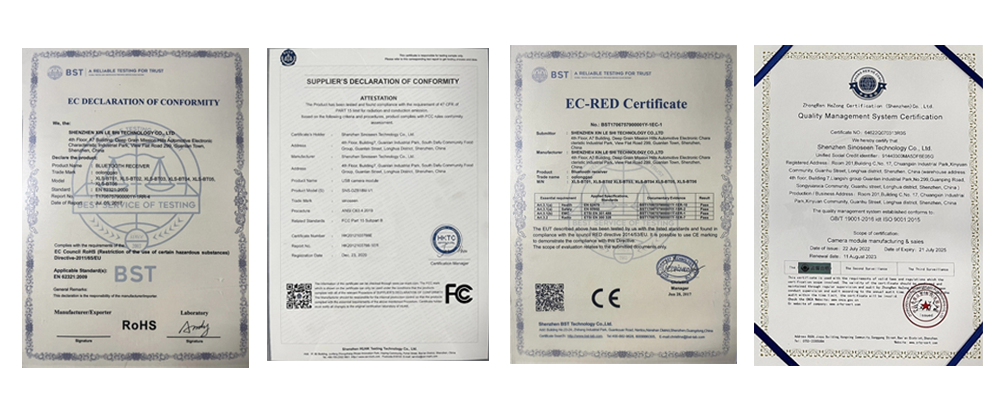

Compliance Package and Supply Chain Security

For China oem cmos camera module procurement, Sinoseen provides a robust compliance package, including REACH and FCC certifications to meet international regulatory demands.7 Our supply chain security incorporates end-to-end traceability via RFID tagging, sourcing components solely from certified vendors to achieve 98% on-time delivery rates, aligning with Semiconductor Industry Association (SIA) best practices.8 Dual-site inventory in Asia mitigates risks from global events, ensuring stable flow for B2B partners.

Volume Production Risk Matrix and After-Sales KPIs

Sinoseen's risk matrix for oem cmos camera module factory scaling evaluates threats on a 1-5 scale, informed by our sub-1% defect history over a decade.

| Risk Type | Likelihood (1-5) | Impact (1-5) | Countermeasure |

|---|---|---|---|

| Supply Delays | 2 | 3 | Strategic stockpiling (2-month buffer) |

| Quality Variance | 1 | 2 | Inline SPC monitoring9 |

| Shipping Disruptions | 3 | 3 | Multi-carrier options (air/sea, 8-15 days to overseas) |

| Spec Drift | 2 | 2 | Automated calibration protocols |

After-sales KPIs include Issue Response <48 hours (97% compliance in 2024), Fix Rate >92% in 5 days, and NPS >4.2/5, fostering enduring client relationships.

Common Procurement Questions

- What timelines apply to wholesale oem cmos camera module bulk orders? Samples dispatch in 1-2 weeks; volume production in 4 weeks, with international shipping via express (8-12 days) or sea (15-20 days) from China.

- How does Sinoseen support customized oem cmos camera module for MIPI interfaces? We offer full ODM adaptation, including pinout reconfiguration and driver kits, validated on client prototypes within our 1-week iteration cycle.

- What certifications back China oem cmos camera module manufacturers like yours? ISO 9001, RoHS, and CE, with batch-specific test reports ensuring adherence to global OEM standards.

- Can oem cmos camera module suppliers provide scalability for 10K+ units? Absolutely; our flexible lines handle surges with MOQs from 100 units, supported by capacity planning tools for just-in-time delivery.

- What integration aids exist for oem cmos camera module factory modules in embedded Linux? Comprehensive UVC SDKs, sample code, and virtual support sessions enable setup in under 48 hours for most systems.

Footnotes

1 Pixel size refers to the physical dimensions of individual light-sensitive elements on the sensor, influencing light sensitivity. 2 UVC: USB Video Class, a standard for video streaming over USB without additional software. 3 IIA 2023 Report on Imaging Sensor Efficiency. 4 CMOS: Complementary Metal-Oxide-Semiconductor, enabling faster readout and lower power than traditional sensors. 5 Derived from Sinoseen 2022-2024 project metrics. 6 MTBF: Mean Time Between Failures, a key reliability indicator for electronic components. 7 REACH: EU regulation on chemical safety in products; FCC: Federal Communications Commission standards for emissions. 8 SIA 2024 Supply Chain Resilience Guidelines. 9 SPC: Statistical Process Control, a method for monitoring production variability.

Industry Common Challenges and Solutions

- Challenge: Interface Incompatibilities in Legacy HardwareSolution: Universal adapter kits and cross-platform testing, slashing integration errors by 35%.

- Challenge: Component Sourcing VolatilitySolution: Diversified vendor networks and predictive analytics for 99% availability.

- Challenge: Overheating in Compact EnclosuresSolution: Optimized thermal profiles tested to 60°C, with airflow simulations per IPC standards.

- Challenge: Firmware ObsolescenceSolution: Modular update frameworks compatible with OTA, ensuring longevity beyond 5 years.

- Challenge: Demand Forecasting ErrorsSolution: Collaborative planning with ERP integration, buffering 15% excess capacity for peaks.

EN

EN

AR

AR

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

SR

SR

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

MS

MS

IS

IS

AZ

AZ

UR

UR

BN

BN

HA

HA

LO

LO

MR

MR

MN

MN

PA

PA

MY

MY

SD

SD