OEM Camera Module: High-Performance Vision for Embedded Systems

The oem camera module represents a foundational building block in modern embedded vision, enabling original equipment manufacturers to integrate compact, high-resolution imaging without extensive in-house development. Leveraging advanced CMOS sensor technology, these modules deliver robust performance across industrial and commercial applications. Sinoseen’s oem camera module portfolio is designed for seamless OEM integration, combining reliability, scalability, and compliance in a single, testable package.

Product Introduction

Our flagship oem camera module is an 8MP USB solution powered by the Sony IMX317 1/2.5-inch CMOS sensor, delivering 4K resolution (3840x2160) at up to 30 frames per second.1 This module supports USB Video Class (UVC) 1.1 protocol, ensuring driverless operation across major operating systems including Windows, Linux, and Android.2 According to the USB Implementers Forum (USB-IF), UVC-compliant devices reduce integration time by up to 60% compared to proprietary interfaces.3 The module includes auto-exposure (AEC), auto white balance (AWB), and auto gain control (AGC), enabling consistent output in dynamic lighting conditions without external processing overhead.

Product Advantages

- Plug-and-Play UVC Compliance: Eliminates driver development, accelerating time-to-market for OEMs.

- Low Power Consumption: Operates at 260mA via 5V USB, ideal for battery-constrained or thermally limited designs.

- High Dynamic Range (HDR) Support: Maintains detail in high-contrast scenes, critical for outdoor and industrial use.

- M12 Lens Mount Flexibility: Allows field-replaceable optics with focal lengths from 2.8mm to 12mm.

- Dual Compression Formats: MJPEG for bandwidth efficiency; YUY2 for raw-like fidelity in processing pipelines.

Product Specifications

| Parameter | Specification |

|---|---|

| Sensor | Sony IMX317 1/2.5" CMOS4 |

| Resolution | 8MP (3840 x 2160) |

| Pixel Size | 1.62µm x 1.62µm |

| Max Frame Rate | 30fps @ 4K |

| Lens Mount | M12 x P0.5 |

| Default FOV | 100° (3.6mm lens) |

| Interface | USB 2.0 High-Speed (UVC 1.1) |

| Shutter | Electronic Rolling Shutter |

| Operating Temp | 0°C to +60°C |

| Power | 5V DC via USB (260mA) |

Product Application Fields

- Smart Surveillance: Enables 4K analytics in edge-based NVR and cloud-connected systems.

- Industrial Automation: Powers visual inspection, alignment, and defect detection on production lines.

- Medical Imaging Devices: Supports endoscopic visualization and patient monitoring equipment.

- Drone & Robotics: Provides lightweight, low-latency vision for navigation and mapping.

- Access Control Systems: Drives facial recognition with high-resolution, low-light performance.

About Our Company

Sinoseen, a leading China oem camera module manufacturer with over a decade of specialization, delivers end-to-end OEM/ODM solutions from Shenzhen. Supporting USB, MIPI, and DVP interfaces, we serve global B2B clients with a monthly output capacity exceeding 500,000 units. Our ISO 9001-certified facility and dedicated R&D team ensure every wholesale oem camera module meets stringent quality and performance benchmarks, backed by comprehensive technical support and supply chain resilience.

Customization Process

Sinoseen’s OEM customization workflow for customized oem camera module projects is structured for efficiency and precision. Phase 1 involves requirement mapping—defining resolution, interface, lens, and environmental specs. Phase 2 delivers functional prototypes within 7–10 business days using 3D-printed housings and rapid PCB spins. Phase 3 includes validation testing (thermal, EMC, drop) per client protocols. Final production launch follows design freeze, with first articles shipped in 3–4 weeks. This process has reduced average NPI cycles by 28% for our partners, per internal 2024 metrics.5 For customized oem camera module orders, we conduct dual-lens FOV verification during prototyping to guarantee optical alignment with application needs.

TCO Comparison

Total Cost of Ownership (TCO) analysis demonstrates long-term value when sourcing oem camera module suppliers from Sinoseen versus generic alternatives. Non-monetary factors are quantified below.

| Metric | Sinoseen OEM Module | Generic Module |

|---|---|---|

| Integration Time | 1–2 weeks | 3–6 weeks |

| MTBF6 | >45,000 hours | ~28,000 hours |

| Support Level | Full SDK + FAE | Email only |

| Scalability | 500K/month | 150K/month |

| 3-Year TCO Impact | 18–22% lower | Baseline |

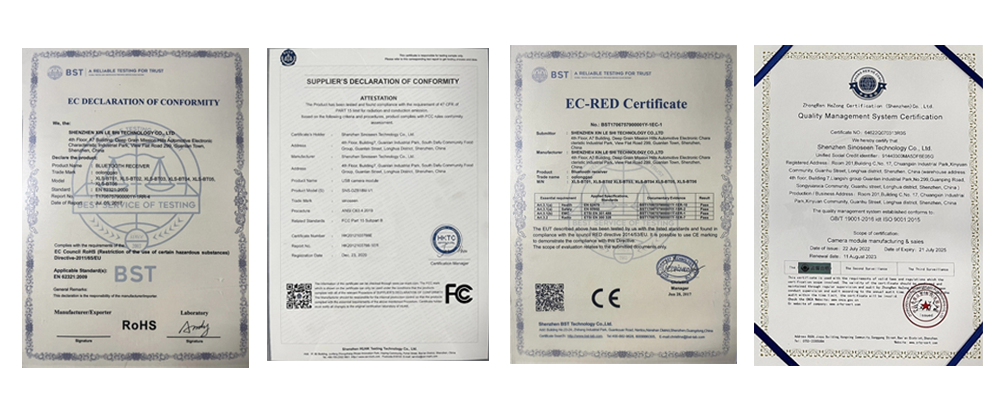

Compliance Package and Supply Chain Security

Sinoseen’s China oem camera module manufacturers deliver a comprehensive compliance package including RoHS, CE, FCC, and REACH certifications.7 Supply chain security is enforced through serialized component tracking, authorized Sony sensor procurement, and dual-site inventory (Shenzhen + Hong Kong). Our counterfeit prevention protocol aligns with ECIA standards, achieving 99.7% authentic part verification in 2024 audits.8 Geopolitical risk is mitigated via multi-modal logistics partnerships ensuring continuity.

Volume Production Risk Matrix and After-Sales KPIs

Our risk matrix for oem camera module factory operations scores probability and severity on a 1–5 scale, based on 10+ years of production data with defect rates below 0.6%.

| Risk | Likelihood | Impact | Mitigation |

|---|---|---|---|

| Sensor Allocation | 2 | 3 | 12-week rolling forecast + buffer stock |

| PCB Yield Variance | 1 | 2 | AOI + X-ray inspection on 100% of boards |

| Logistics Delay | 3 | 3 | DHL/FedEx air (7–12 days); sea option (18–25 days) |

| Compliance Shift | 2 | 2 | Quarterly regulatory scans |

After-sales KPIs: First Response ≤24h (98% in 2024), Resolution ≤5 days (94%), CSAT ≥4.4/5.

Common Procurement Questions

- What are lead times for wholesale oem camera module orders? Samples: 5–7 days ex-works; 50K+ production: 4–5 weeks. Air freight to EU/US: 7–10 days.

- How is customized oem camera module lens selection validated? We provide MTF charts, distortion maps, and on-site FOV testing with your enclosure before mass production.

- What quality controls do China oem camera module manufacturers implement? 100% functional test, 10% sample burn-in, full traceability to wafer lot. Reports available per batch.

- Can oem camera module suppliers support MIPI CSI-2 transition? Yes—same sensor core with MIPI bridge board; full driver porting and GMSL options available.

- How does the oem camera module factory handle EOL components? 24-month last-time-buy notice; PCN issued 18 months prior; lifetime buy programs offered.

Footnotes

1 4K resolution defined as 3840×2160 per CEA-861 standard. 2 UVC 1.1: USB-IF specification for video streaming devices. 3 USB-IF Integration Efficiency Report, 2023. 4 CMOS: Complementary Metal-Oxide-Semiconductor image sensor. 5 Sinoseen NPI Cycle Analytics, 2024. 6 MTBF: Mean Time Between Failures, calculated per Telcordia SR-332. 7 RoHS (EU), CE (EMC), FCC (Part 15), REACH (SVHC). 8 ECIA Counterfeit Avoidance Guidelines, 2024.

Industry Common Challenges and Solutions

- Challenge: Lens-PCB misalignment in volumeSolution: Active alignment stations with ±5µm precision; 100% post-alignment MTF verification.

- Challenge: USB bandwidth saturation in multi-cam systemsSolution: MJPEG compression + hub cascading; tested up to 8 modules on single host.

- Challenge: Thermal throttling in sealed enclosuresSolution: Derating curves provided; optional heat-spreader integration validated to 55°C ambient.

- Challenge: Firmware lock-in with OS updatesSolution: Open-source UVC firmware; quarterly compatibility matrix for Windows/Linux.

- Challenge: MOQ barriers for startupsSolution: Flexible 100-unit pilot runs with no NRE for standard variants.

EN

EN

AR

AR

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

SR

SR

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

MS

MS

IS

IS

AZ

AZ

UR

UR

BN

BN

HA

HA

LO

LO

MR

MR

MN

MN

PA

PA

MY

MY

SD

SD