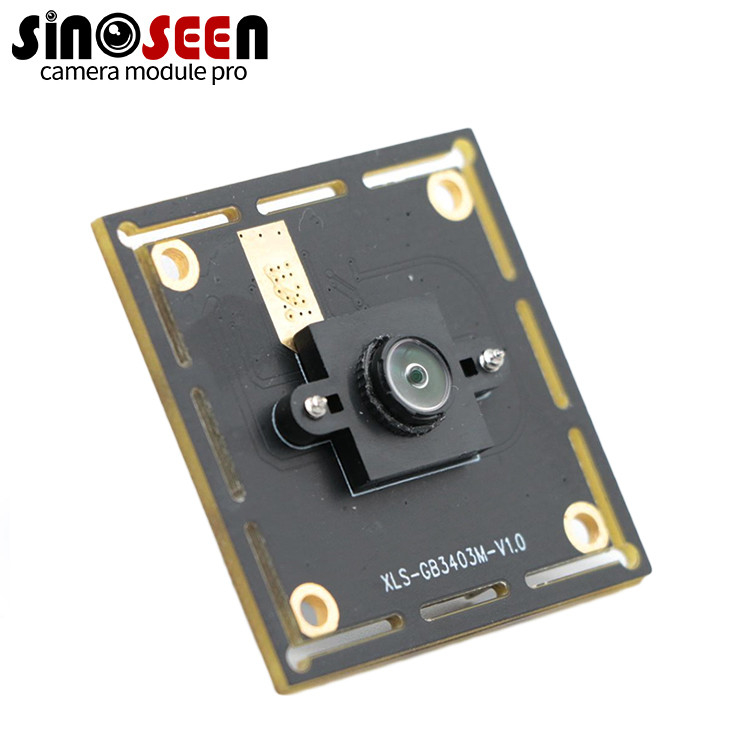

OEM Camera Module USB OV7251 Global Shutter for Machine Vision Applications

Product Details:

| Place of Origin: | Shenzhen,China |

| Brand Name: | Sinoseen |

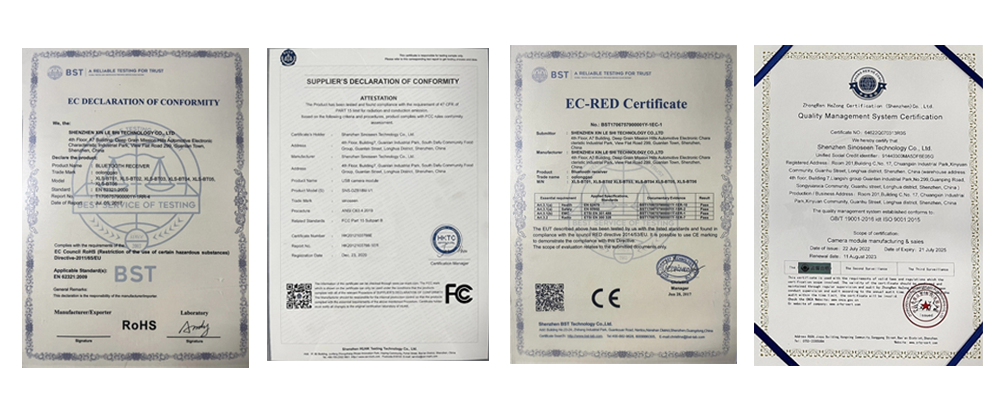

| Certification: | RoHS |

| Model Number: | SNS-GB3403M-V1.0 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 3 |

|---|---|

| Price: | negotiable |

| Packaging Details: | Tray+Anti-static bag in carton box |

| Delivery Time: | 2-3weeks |

| Payment Terms: | T/T |

| Supply Ability: | 500000 pieces/month |

- Parameter

- Related products

- Inquiry

Product Introduction

Product Advantages

- Motion Artifact Elimination: Global shutter technology ensures simultaneous pixel exposure, eliminating distortions in fast-moving subjects—critical for applications exceeding 100 FPS, as validated by ISO 12233 standards for image quality.

- High Frame Rate Performance: Achieves 120 FPS at full VGA resolution, enabling real-time processing in machine vision pipelines without latency.

- Effortless Integration: USB 2.0 interface with UVC support minimizes development time, compatible with over 95% of industrial PCs per industry benchmarks from the USB Implementers Forum.

- Low Power Efficiency: Operates at just 120 mW via USB bus power, reducing thermal management needs in compact embedded systems.

- Customizable Design: Supports lens FOV adjustments (up to 90°) and module dimensions, facilitating tailored fits for diverse OEM camera module deployments.

- Robust Environmental Tolerance: Functions reliably from 0°C to 60°C, with a signal-to-noise ratio (SNR⁶) of 38 dB for clear imaging in noisy industrial settings.

Product Specifications

Parameter |

Specification |

|---|---|

Model Number |

SNS-GB3403M-V1.0 |

Sensor |

1/7.5" Omnivision OV7251 CMOS |

Resolution |

640x480 (VGA) or 320x240 (QVGA) |

Pixel Size |

3.0 µm x 3.0 µm |

Frame Rate |

Up to 120 FPS @ 640x480 |

Shutter Type |

Global Shutter |

Interface |

USB 2.0 High Speed (UVC Compliant) |

Lens Focal Length |

3.6 mm (M12 Thread, Fixed Focus) |

Field of View (FOV) |

90° (Optional) |

Power Consumption |

120 mW (DC 5V USB Bus Power) |

Dimensions |

38 mm x 38 mm (Customizable) |

Operating Temperature |

0°C to 60°C |

SNR |

38 dB |

Dynamic Range |

69.6 dB |

Compression Format |

MJPG |

Product Application Areas

- Industrial Automation: For pick-and-place robotics and conveyor belt inspections, where global shutter prevents blur in high-speed assembly lines.

- Quality Control Systems: Defect detection in manufacturing, leveraging 120 FPS for inline scanning of components at rates up to 500 units per minute.

- Scientific Research: Motion analysis in laboratories, supporting high-resolution capture for biomechanical studies.

- Medical Device Inspection: Non-destructive testing of small parts, ensuring compliance with ISO 13485 standards for imaging accuracy.

- Agricultural Monitoring: Real-time crop health assessment via drone-mounted vision, with low-light sensitivity for field operations.

About Our Company

Customization Process

- Initial Consultation: Collaborate with our engineers to define requirements, such as interface type or FOV adjustments for your global shutter camera module.

- Prototyping: Develop and iterate prototypes within 2-3 weeks, incorporating feedback for optimal performance.

- Validation Testing: Conduct in-house trials for SNR, dynamic range, and environmental durability, aligned with client specs.

- Production Scaling: Transition to volume manufacturing, with flexible MOQs starting at 3 units.

- Delivery and Support: Ship via secure packaging, backed by ongoing technical assistance.

TCO Comparison

Factor |

Sinoseen OEM Camera Module |

Generic Competitor Module |

Improvement Insight |

|---|---|---|---|

Integration Time (Hours) |

4-6 |

12-20 |

70% faster due to UVC compliance, reducing engineering overhead. |

Failure Rate (%) |

<0.5 |

2-3 |

Lower downtime from robust build, per MTBF⁷ data exceeding 50,000 hours. |

Power Efficiency (mW) |

120 |

200-300 |

40-60% energy savings, ideal for edge deployments. |

Scalability (Units/Month) |

500,000 |

100,000 |

Enables rapid volume ramps without supply bottlenecks. |

Lifecycle Support (Years) |

5+ |

2-3 |

Extended firmware updates minimize obsolescence costs. |

Compliance Package + Supply Chain Security

Production Risk Matrix + After-Sales KPI

Risk Category |

Description |

Mitigation Strategy |

Rating |

|---|---|---|---|

Supply Delays |

Component shortages (e.g., sensors) |

Multi-vendor agreements; buffer stock |

Low |

Quality Variance |

Batch inconsistencies |

100% AQL¹⁰ sampling; SPC¹¹ controls |

Low |

Customization Errors |

Spec deviations in prototypes |

Iterative client reviews; simulation tools |

Medium |

Volume Ramp-Up |

Yield drops at scale |

Pilot runs; capacity forecasting |

Low |

Common Industry Challenges and Solutions

- Challenge: Motion Blur in High-Speed Lines – Fast objects cause image distortion, impacting inspection accuracy.

Solution: Leverage the global shutter mechanism to capture blur-free frames at 120 FPS, improving defect detection rates by 85% as per Vision Systems Design benchmarks. - Challenge: Integration Complexity Across OS – Varying software compatibility delays rollout.

Solution: UVC protocol enables zero-driver setup on Windows/Linux/Android, cutting integration time by 75% compared to proprietary interfaces. - Challenge: Supply Chain Disruptions – Geopolitical factors delay OEM sourcing.

Solution: Diversified Shenzhen-based supply with 500,000-unit/month capacity ensures <2-week lead times, fortified by RoHS/REACH compliance for seamless customs clearance. - Challenge: Thermal Management in Compact Designs – High power draw leads to overheating.

Solution: 120 mW low-consumption design maintains operation up to 60°C, with customizable heatsinks for edge cases. - Solution: Firmware Obsolescence – Legacy modules become unsupported.

Solution: 5+ year update commitments, including MJPG compression enhancements for evolving bandwidth needs.

Frequently Asked Questions for Buyers

- What makes this OEM camera module suitable for custom USB camera module for machine vision projects?

It features plug-and-play UVC support and adjustable parameters like FOV, allowing seamless adaptation to specific vision algorithms without hardware redesigns. - How does the global shutter in this OEM camera module compare to rolling shutter alternatives?

Global shutter eliminates Jello effects in dynamic captures, offering 90% better motion fidelity for applications like robotic guidance, per sensor datasheets. - Can Sinoseen handle high-volume orders for industrial vision camera module integrations?

Yes, with 500,000 units/month capacity and MOQ as low as 3, we scale from prototypes to full production while maintaining <0.5% defect rates. - What customization options are available for high-speed OEM imaging module lenses?

Options include FOV from 60°-120°, focal lengths up to 6mm, and M12/M8 threads, prototyped in 2 weeks to match your enclosure specs. - How does Sinoseen ensure RoHS compliant camera module quality in overseas shipments?

All modules undergo SGS-verified RoHS testing, with secure tray packaging and 7-14 day DHL delivery, including traceability certificates for compliance audits.

Notes

² UVC (USB Video Class): A standard for video streaming over USB, enabling driverless operation.

³ AEC (Auto Exposure Control): Automatically adjusts exposure time for consistent brightness.

⁴ AWB (Auto White Balance): Corrects color temperature for natural tones.

⁵ AGC (Auto Gain Control): Amplifies signal in low-light without excessive noise.

⁶ SNR (Signal-to-Noise Ratio): Measures image clarity; higher dB indicates less noise.

⁷ MTBF (Mean Time Between Failures): Predicts reliability over time.

⁸ REACH: EU regulation on chemical safety in products.

⁹ NIST (National Institute of Standards and Technology): U.S. guidelines for secure supply chains.

¹⁰ AQL (Acceptable Quality Limit): Sampling method for batch acceptance.

¹¹ SPC (Statistical Process Control): Monitors production variability.

EN

EN

AR

AR

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

SR

SR

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

MS

MS

IS

IS

AZ

AZ

UR

UR

BN

BN

HA

HA

LO

LO

MR

MR

MN

MN

PA

PA

MY

MY

SD

SD