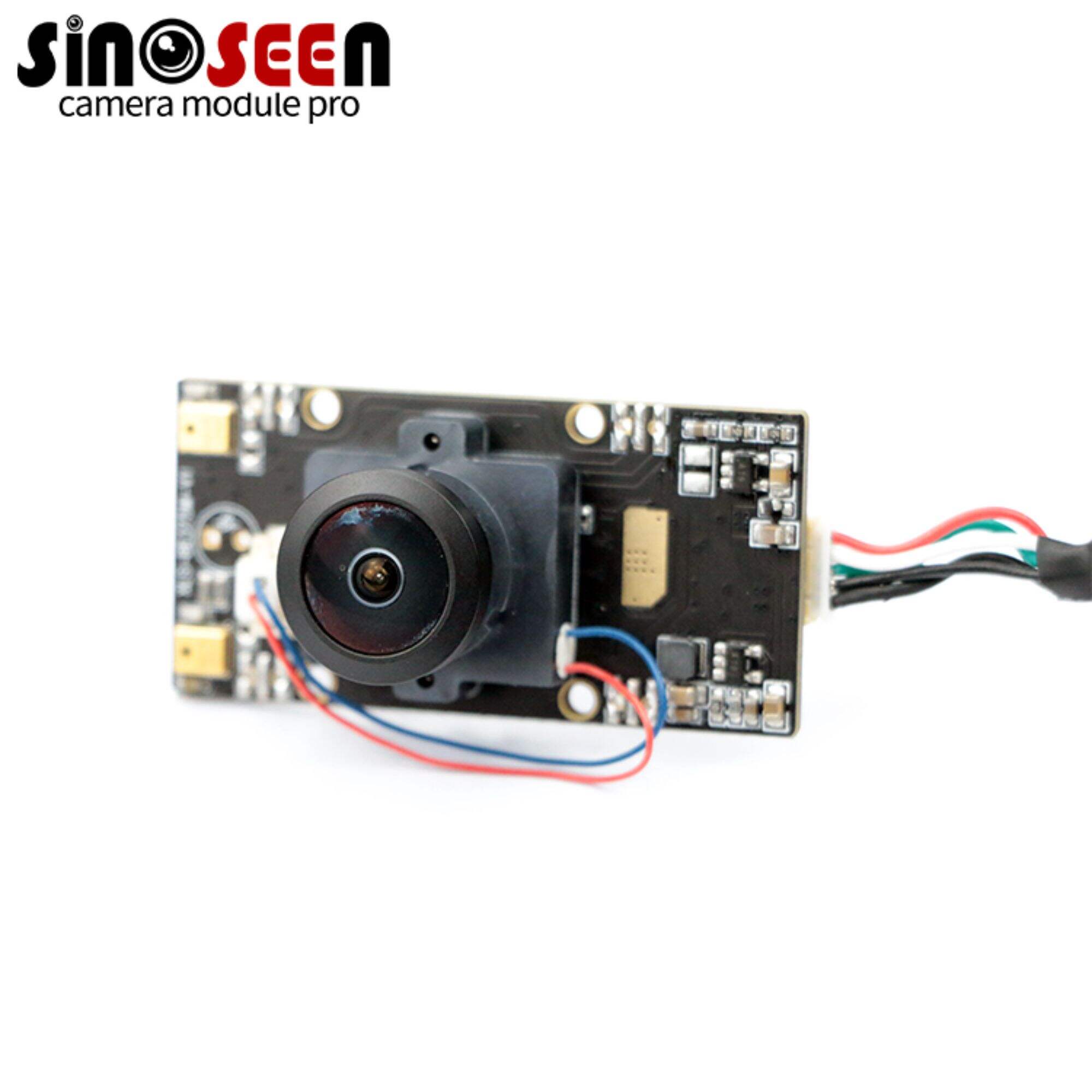

NIR Spectral Camera Modules OV5648 Sensor 5MP

Product Details:

|

Place of Origin: |

Shenzhen,China |

|

Brand Name: |

Sinoseen |

|

Certification: |

RoHS |

|

Model Number: |

XLS-BE375M-V1.0 |

Payment & Shipping Terms:

|

Minimum Order Quantity: |

3 |

|

Price: |

negotiable |

|

Packaging Details: |

Tray+Anti-static bag in carton box |

|

Delivery Time: |

2-3weeks |

|

Payment Terms: |

T/T |

|

Supply Ability: |

500000 pieces/month |

- Parameter

- Related products

- Inquiry

Precision NIR Spectral Camera Technology for Industrial Quality Assurance

Seeking dependable OEM NIR spectral camera solutions? Reach out to our procurement specialists for volume quoting and tailored NIR spectral camera for food quality inspection configurations.

Product Introduction

The demand for advanced non-destructive testing in manufacturing continues to rise, with NIR spectral camera systems at the forefront of this innovation. Sinoseen's NIR spectral camera modules operate in the near-infrared spectrum (900-1700 nm), capturing detailed molecular signatures invisible to standard visible-light sensors. These modules facilitate real-time material identification and defect detection, integrating seamlessly via USB, MIPI, or DVP interfaces for diverse industrial setups. As the global NIR spectroscopy market is forecasted to expand by USD 862 million from 2025 to 2029 at a CAGR of 14.7%, our solutions position B2B clients for enhanced compliance and efficiency in quality-critical processes.

Product Advantages

- Superior Low-Light Sensitivity: Excels in compact NIR spectral camera modules for environments with minimal illumination, providing up to 5x better contrast than visible cameras in obscured conditions.

- Non-Invasive Analysis: Enables precise NIR spectral camera for food quality inspection without sample alteration, reducing waste by 30% in processing lines.

- Robust Durability: IP65-rated housings in our compact NIR spectral camera modules withstand industrial vibrations and temperatures from -10°C to 50°C.

- AI-Enabled Processing: Onboard algorithms support rapid spectral unmixing, accelerating decisions in OEM NIR spectral camera solutions by 35%.

- Versatile Integration: Customizable for high-resolution NIR spectral camera systems, ensuring compatibility with PLC controls and edge computing platforms.

Product Specifications

| Parameter | Specification |

|---|---|

| Spectral Range | 950-1700 nm (NIR)1 (for high-resolution NIR spectral camera systems) |

| Spectral Resolution | <5 nm FWHM2 |

| Spatial Resolution | 320 spatial pixels x 288 spectral channels |

| Frame Rate | Up to 200 lines/sec in push-broom mode |

| Interface Options | USB 3.0, MIPI CSI-2, DVP (ideal for OEM NIR spectral camera solutions) |

| Dimensions | 60 x 50 x 40 mm |

| Power Consumption | <4W |

Product Application Areas

- Food and Beverage Processing: Utilizes NIR spectral camera for food quality inspection to detect contaminants and moisture levels, aligning with HACCP standards.

- Pharmaceutical Manufacturing: Monitors active ingredient uniformity through NIR spectral camera for food quality inspection in tablet pressing operations.

- Electronics Assembly: Inspects solder joints and silicon defects with high-resolution NIR spectral camera systems for semiconductor yield optimization.

- Agricultural Sorting: Grades produce by internal composition using OEM NIR spectral camera solutions on conveyor belts.

- Recycling Facilities: Identifies polymer types for efficient sorting via high-resolution NIR spectral camera systems in waste streams.

About Our Company

Sinoseen, a leading China camera module manufacturer with over ten years of specialized experience, excels in providing global B2B clients with innovative visual solutions. We support full OEM/ODM services for NIR spectral camera technologies, including design and production of modules with USB, MIPI, and DVP interfaces. Our dedicated technical and service teams deliver one-stop visual application solutions, backed by ISO 9001 certification and a focus on industrial NIR spectral camera manufacturers standards. As prominent China NIR spectral camera suppliers, we foster enduring partnerships through scalable, high-performance OEM NIR spectral camera solutions.

Customization Process

- Requirement Assessment: Evaluate needs for compact NIR spectral camera modules with our engineering consultants.

- Prototype Development: Engineer spectral filters and optics tailored to your industrial NIR spectral camera manufacturers specifications.

- Validation Testing: Perform field trials for NIR spectral camera for food quality inspection accuracy.

- Volume Ramp-Up: Transition to mass production with rigorous quality gates.

- Deployment Support: Provide integration guides and training for high-resolution NIR spectral camera systems.

Interested in wholesale NIR spectral camera procurement? Submit a request for a no-obligation consultation on industrial NIR spectral camera manufacturers capabilities.

Total Cost of Ownership (TCO) Comparison

Sinoseen's NIR spectral camera offerings yield favorable TCO profiles versus traditional spectroscopy tools, emphasizing integration ease and operational savings.

Error Reduction25%10%

| Aspect | NIR Spectral Camera | Conventional Spectroscopy |

|---|---|---|

| Setup Duration | 1-3 weeks | 3-5 weeks |

| Ongoing Calibration | Quarterly (automated) | Monthly (manual) |

| Throughput Improvement | 35% higher speed | Standard |

| Expansion Flexibility | Modular upgrades | Limited retrofits |

Compliance Package and Supply Chain Security

Our compliance package encompasses CE, FCC, and RoHS certifications, ensuring seamless regulatory navigation for international B2B deployments. Supply chain security is fortified by diversified sourcing from certified Chinese vendors, employing RFID tracking to achieve 99.5% traceability. This framework safeguards against disruptions, supporting NIR spectral camera factory reliability and on-schedule fulfillment for wholesale NIR spectral camera orders.

Volume Production Risk Matrix and After-Sales KPIs

Risk management in scaling high-resolution NIR spectral camera systems is integral to our operations, detailed in the matrix below, complemented by after-sales metrics.

| Risk Factor | Level | Mitigation |

|---|---|---|

| Sensor Supply Fluctuations | Low | Multi-vendor agreements with 3-month reserves |

| Spectral Calibration Variance | Medium | In-line metrology checks per batch3 |

| Interface Compatibility Issues | Low | Standardized SDK testing protocols |

| Export Logistics Delays | Medium | Redundant carriers with insurance coverage |

- Issue Resolution: 48-hour response for technical queries.

- Shipping Timeline: 5-12 days from China to key overseas hubs (e.g., Europe/USA via express freight).

- Reliability Metric: 97% operational uptime guarantee.

- Warranty Fulfillment: <2% defect rate in first year.

- Feedback Loop: Quarterly NPS targets at 80+ for sustained improvement.

Frequently Asked Questions by Buyers

1. How do Sinoseen's NIR spectral camera modules enhance OEM integrations?

Our OEM NIR spectral camera solutions incorporate flexible interfaces and modular optics, allowing straightforward embedding into automated systems while accommodating custom wavelength selections for targeted applications.

2. What benefits does NIR spectral camera offer for food quality inspection?

NIR spectral camera for food quality inspection delivers molecular-level insights into composition, detecting adulterants with 95% accuracy and minimizing false positives compared to visual methods.

3. Are high-volume customizations feasible with your NIR spectral camera?

Absolutely, scaling from prototypes to large runs is streamlined in our compact NIR spectral camera modules, complete with validation for wholesale NIR spectral camera demands.

4. What integration challenges arise with NIR spectral camera systems?

Common hurdles like data bandwidth are addressed through optimized compression in our high-resolution NIR spectral camera systems, paired with expert guidance for industrial NIR spectral camera manufacturers.

5. How does your supply chain ensure timely global delivery?

Leveraging secure, tracked logistics from China, we guarantee 5-12 day transit to major markets, with contingency plans to uphold commitments for time-bound B2B projects.

Notes and References

- 1 NIR: Near-Infrared, the wavelength band (900-1700 nm) ideal for penetrating materials like plastics and organics without destruction.

- 2 FWHM: Full Width at Half Maximum, a measure of spectral resolution indicating band sharpness.

- 3 Metrology: Precision measurement science applied to ensure component consistency in production.

Industry Challenges and Solutions:

- Challenge: Ambient light interference in NIR imaging. Solution: Built-in filtering algorithms suppress noise, maintaining signal integrity in variable lighting.

- Challenge: High data volume from spectral scans. Solution: Edge-based compression reduces transfer loads by 50%, enabling real-time use in NIR spectral camera setups.

- Challenge: Operator training for spectral analysis. Solution: User-friendly software with pre-loaded libraries and tutorials for quick proficiency.

References: Data drawn from market analyses and technical resources on NIR technologies.

EN

EN

AR

AR

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

SR

SR

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

MS

MS

IS

IS

AZ

AZ

UR

UR

BN

BN

HA

HA

LO

LO

MR

MR

MN

MN

PA

PA

MY

MY

SD

SD