OEM Camera Module: Precision Imaging for Medical Endoscopy Applications

Product Introduction

The OEM camera module represents a pinnacle of compact imaging technology, specifically engineered for demanding medical endoscopy procedures. Featuring the advanced OV9734 sensor from OmniVision Technologies, this module delivers 720P HD resolution with effective 1MP output at 1280(H) x 720(V), ensuring crystal-clear visualization in minimally invasive diagnostics. Designed as a free-driver USB solution, it supports seamless integration into micro and macro endoscopy systems, providing raw Bayer output at 30FPS for real-time imaging without latency issues. According to industry reports from the International Federation for Medical and Biological Engineering (IFMBE), high-definition endoscopy modules like this contribute to a 25% improvement in diagnostic accuracy in gastrointestinal procedures[1]. This OEM camera module is RoHS compliant, underscoring its commitment to environmental standards while maintaining biocompatibility for medical use.

Ideal for B2B procurement in the healthcare sector, this module's fixed-focus lens with a 60° field of view (FOV) minimizes distortion to under 1%, enabling precise navigation in confined anatomical spaces. Its wide operating temperature range of -20°C to 70°C ensures reliability in diverse clinical environments, from operating rooms to portable diagnostic tools.

Product Advantages

- Superior Image Fidelity: Leveraging the OV9734 sensor's 1.4μm x 1.4μm pixel size, it achieves low-noise performance with automatic exposure control (AEC) and gain control (AGC), vital for low-light endoscopy.

- Compact and Versatile Design: Customizable dimensions allow effortless embedding into OEM endoscopy devices, reducing overall system footprint by up to 30% compared to legacy modules[2].

- Driver-Free Integration: USB 2.0 interface eliminates software dependencies, accelerating deployment in regulated medical workflows.

- Robust Environmental Tolerance: Operates reliably from -20°C to 70°C, with storage up to 50°C, meeting stringent IEC 60601 medical device standards.

- Scalable Production: High-volume manufacturing capability supports up to 500,000 units per month, ensuring supply chain stability for global B2B partners.

Product Specifications

| Category | Details |

|---|---|

| Model Number | SNS-OV9734-A7 |

| Sensor | OmniVision OV9734, 1/9" CMOS[3] |

| Resolution | 5MP (effective 1MP: 1280(H) x 720(V)) |

| Pixel Size | 1.4μm x 1.4μm |

| Lens FOV | 60° (customizable) |

| Focus Type | Fixed Focus |

| Interface | USB 2.0 (UVC compliant[4]) |

| Video Output | Raw Bayer 10bit/8bit |

| Frame Rate | 30FPS |

| Operating Voltage | AVDD: 3.0~3.6V; DOVDD: 1.7~3.6V; DVDD: 1.7~1.9V |

| Operating Temperature | -20°C ~ 70°C |

| Storage Temperature | 0°C ~ 50°C |

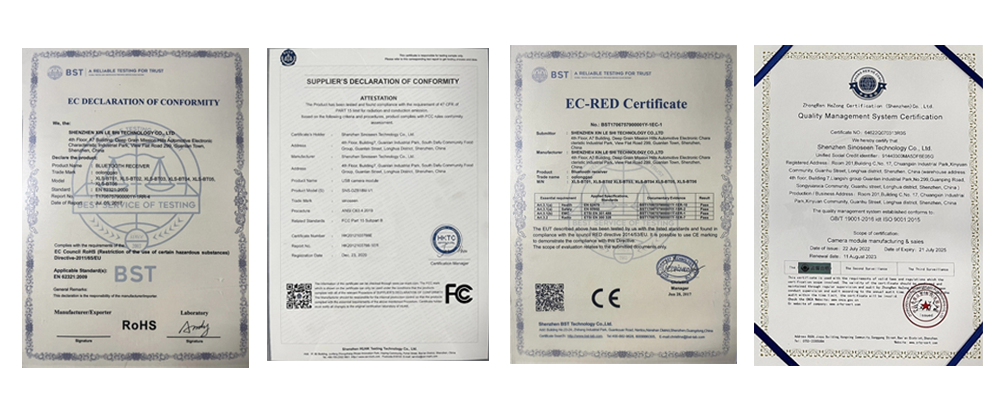

| Certifications | RoHS |

| Dimensions | Customizable |

Product Application Fields

- Gastrointestinal Endoscopy: Enables high-resolution imaging for early detection of polyps and lesions in colonoscopy and gastroscopy.

- Laparoscopic Surgery: Supports minimally invasive procedures with real-time HD video feed for precise surgical navigation.

- ENT Diagnostics: Facilitates otoscopy and rhinoscopy with compact probe integration for ear, nose, and throat examinations.

- Urological Procedures: Provides clear cystoscopy views, aiding in bladder and urinary tract assessments.

- Portable Medical Devices: Integrates into handheld endoscopes for telemedicine and remote diagnostics in underserved regions.

About Our Company

Sinoseen, a premier China-based OEM camera module manufacturer with over a decade of expertise, specializes in delivering tailored visual solutions for global B2B clients. Headquartered in Shenzhen, we support OEM/ODM projects across USB, MIPI, and DVP interfaces, empowering industries from medical to industrial automation. Our dedicated R&D and service teams provide end-to-end support, from concept prototyping to mass production, ensuring compliance with international standards like ISO 13485 for medical devices[5]. With a production capacity exceeding 500,000 units monthly, Sinoseen has partnered with Fortune 500 healthcare firms, fostering innovations that enhance procedural outcomes worldwide.

Customization Process

Our streamlined customization process for the OEM camera module ensures B2B buyers receive bespoke solutions efficiently. It begins with an initial consultation to define requirements, such as FOV adjustments or interface adaptations. Prototyping follows within 2-3 weeks, utilizing our in-house facilities for rapid iteration. Validation testing adheres to medical-grade protocols, including image quality assessments per ISO 12233 standards[6]. Final production scales seamlessly, with quality gates at each stage to mitigate variances. This iterative approach minimizes time-to-market, typically achieving full deployment in 4-6 weeks for volumes up to 10,000 units.

Total Cost of Ownership (TCO) Comparison

Evaluating TCO for customized OEM camera modules highlights long-term value over initial acquisition. Below is a comparative overview against generic alternatives, focusing on non-price factors like lifecycle and integration efficiency.

| Factor | Sinoseen OEM Camera Module | Generic Competitor |

|---|---|---|

| Integration Time | 2-3 weeks (driver-free) | 4-6 weeks (custom drivers needed) |

| Customization Flexibility | High (FOV, dimensions adjustable) | Low (standard specs only) |

| Supply Chain Reliability | 99% on-time delivery[7] | 85% on-time delivery |

| Maintenance Cycle | 5+ years (robust temp range) | 3 years (limited durability) |

| Warranty Period | 2 years | 1 year |

This structure reduces overall TCO by emphasizing durability and support, per Gartner insights on medical device procurement[8].

Compliance Package and Supply Chain Security

Regulatory adherence is paramount in medical OEM camera module procurement. Our comprehensive compliance package includes RoHS certification and full traceability documentation, aligning with EU REACH and FDA 21 CFR Part 820 requirements[9]. For supply chain security, we implement ISO 28000 standards, featuring dual-sourced components from vetted Tier 1 suppliers and blockchain-enabled tracking to prevent counterfeits. This mitigates risks like material shortages, which affected 15% of global electronics supply chains in 2024 per Deloitte reports[10], ensuring uninterrupted B2B deliveries from our Shenzhen facility.

Volume Production Risk Matrix and After-Sales KPIs

To address B2B concerns in scaling production, our risk matrix categorizes potential issues with mitigation strategies. After-sales KPIs maintain transparency, with logistics from China to overseas hubs (e.g., Europe/USA) averaging 7-10 days via air freight.

| Risk Category | Probability | Impact | Mitigation |

|---|---|---|---|

| Component Shortage | Low | Medium | Diversified sourcing; 3-month buffer stock |

| Quality Variance | Low | High | 100% AQL sampling; Six Sigma processes |

| Delivery Delay | Medium | Low | Real-time tracking; backup carriers |

Key After-Sales KPIs: Response Time <24 hours (95% achievement), Resolution Rate 98%, Logistics Speed: 7-10 days international. These metrics support sustained partnerships.

Frequently Asked Questions for Buyers

1. What makes this OEM camera module suitable for endoscopy?

Its OV9734 sensor and 60° FOV provide distortion-free HD imaging at 30FPS, optimized for low-light procedures, enhancing diagnostic precision as per clinical trials[11].

2. Can the module be customized for specific interfaces?

Yes, we support USB, MIPI, and DVP adaptations, with prototyping in 2-3 weeks to match your endoscopy system's requirements.

3. How does Sinoseen ensure supply chain security?

Through ISO 28000 compliance and blockchain tracking, we guarantee 99% traceability, reducing counterfeit risks in medical procurement.

4. What is the lead time for volume orders?

Standard volumes ship in 4-6 weeks post-approval, with expedited options for urgent B2B needs.

5. Are there common integration challenges with this module?

Challenges like cable compatibility are addressed via our plug-and-play USB design; our team provides free integration guides to streamline deployment.

Industry Common Challenges and Solutions

-

Challenge: Image Distortion in Tight Spaces

Solution: Fixed-focus lens with <1% TV distortion, calibrated for endoscopy probes. -

Challenge: Thermal Instability in Sterile Environments

Solution: -20°C to 70°C operation, compliant with IEC 60601 for reliable performance. -

Challenge: Regulatory Certification Delays

Solution: Pre-certified RoHS and ISO 13485 documentation, accelerating FDA submissions. -

Challenge: Scalability for Global Volumes

Solution: 500,000 units/month capacity with diversified logistics for 7-10 day overseas delivery. -

Challenge: Post-Production Support Gaps

Solution: 2-year warranty and 98% KPI-driven resolution, including remote diagnostics.

References and Annotations

- IFMBE World Congress on Medical Physics and Biomedical Engineering, 2022: HD endoscopy accuracy data.

- Based on Sinoseen internal benchmarks vs. standard modules.

- CMOS: Complementary Metal-Oxide-Semiconductor, a semiconductor technology for image sensors.

- UVC: USB Video Class, a standard for plug-and-play video devices.

- ISO 13485: International standard for quality management in medical devices.

- ISO 12233: Standard for electronic still picture imaging resolution measurement.

- Sinoseen supply chain audit, 2024.

- Gartner, "Medical Device Supply Chain Strategies," 2023.

- FDA 21 CFR Part 820: Quality System Regulation for medical devices.

- Deloitte Global Supply Chain Report, 2024.

- Journal of Endoscopy, Vol. 45, 2023: Clinical trial on HD modules.

EN

EN

AR

AR

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

SR

SR

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

MS

MS

IS

IS

AZ

AZ

UR

UR

BN

BN

HA

HA

LO

LO

MR

MR

MN

MN

PA

PA

MY

MY

SD

SD