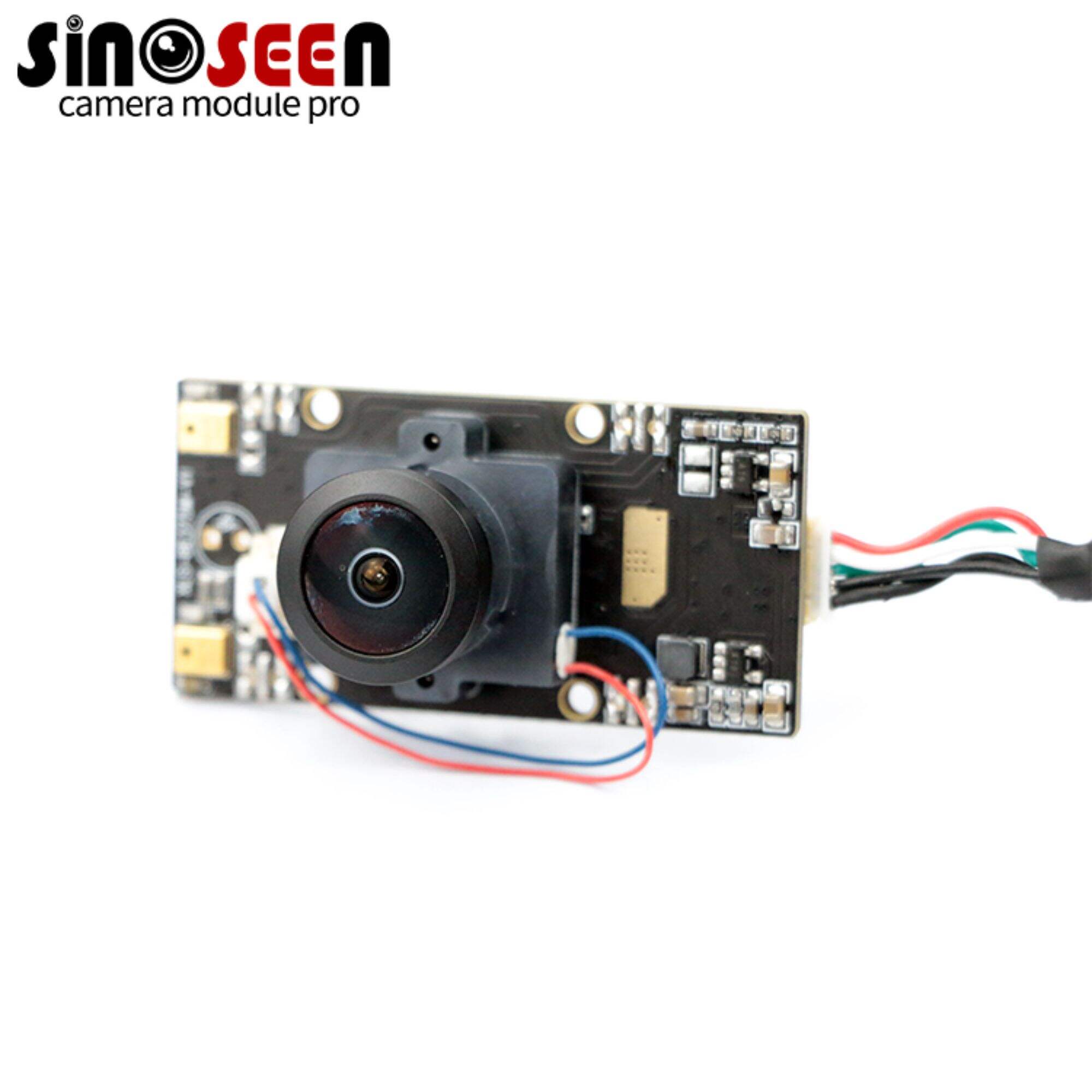

Industrial Hyperspectral Imaging Modules OV5648

Product Details:

|

Place of Origin: |

Shenzhen,China |

|

Brand Name: |

Sinoseen |

|

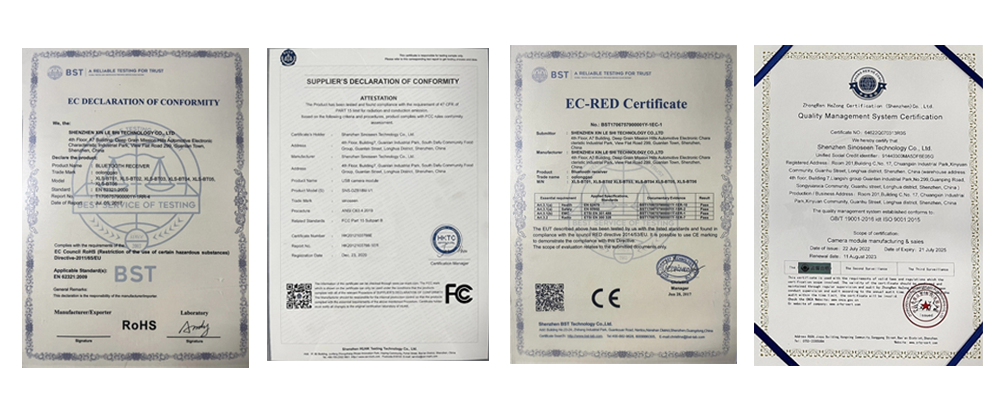

Certification: |

RoHS |

|

Model Number: |

XLS-BE375M-V1.0 |

Payment & Shipping Terms:

|

Minimum Order Quantity: |

3 |

|

Price: |

negotiable |

|

Packaging Details: |

Tray+Anti-static bag in carton box |

|

Delivery Time: |

2-3weeks |

|

Payment Terms: |

T/T |

|

Supply Ability: |

500000 pieces/month |

- Parameter

- Related products

- Inquiry

Advanced Industrial Hyperspectral Imaging Solutions for Precision Manufacturing

Looking for reliable OEM industrial hyperspectral imaging solutions? Contact our sales team today to discuss bulk procurement options and customized configurations tailored to your production needs.

Product Introduction

In the evolving landscape of modern manufacturing, industrial hyperspectral imaging stands out as a transformative technology for non-destructive material analysis. At Sinoseen, our industrial hyperspectral imaging modules capture hundreds of narrow spectral bands across the visible and near-infrared (VNIR) spectrum, enabling precise identification of material compositions, defects, and contaminants at the molecular level. These compact industrial hyperspectral imaging modules are designed for seamless integration into automated production lines, supporting interfaces like USB, MIPI, and DVP for versatile deployment. With the global hyperspectral imaging systems market projected to reach USD 28.63 billion by 2030, growing at a CAGR of 10.6%, our solutions empower B2B clients to achieve superior quality assurance without compromising efficiency.

Product Advantages

- Enhanced Spectral Resolution: Captures over 200 contiguous bands for detailed industrial hyperspectral imaging for quality control, outperforming traditional RGB cameras in defect detection accuracy by up to 95%.

- Compact and Robust Design: Our compact industrial hyperspectral imaging modules feature IP67-rated enclosures, ideal for harsh industrial hyperspectral imaging in manufacturing environments.

- Real-Time Processing: Integrated AI algorithms enable on-the-fly analysis, reducing inspection times by 40% in high-volume production.

- Scalable OEM Integration: Supports OEM industrial hyperspectral imaging solutions with customizable spectral ranges, ensuring compatibility with existing PLC and vision systems.

- Cost-Effective Longevity: Low power consumption (under 5W) and minimal maintenance extend ROI in industrial hyperspectral imaging for quality control applications.

Product Specifications

| Parameter | Specification |

|---|---|

| Spectral Range | 400-1000 nm (VNIR)1 |

| Spatial Resolution | 1024 x 512 pixels (for high-resolution industrial hyperspectral imaging systems) |

| Spectral Bands | 270 contiguous bands |

| Frame Rate | Up to 100 fps in snapshot mode |

| Interface Options | USB 3.0, MIPI CSI-2, DVP (for compact industrial hyperspectral imaging modules) |

| Dimensions | 50 x 50 x 30 mm |

| Operating Temperature | -10°C to 60°C |

Product Application Areas

- Quality Control in Food Processing: Detects foreign materials and spoilage using industrial hyperspectral imaging for quality control, ensuring compliance with FDA standards.

- Pharmaceutical Inspection: Identifies pill coatings and impurities via high-resolution industrial hyperspectral imaging systems for batch traceability.

- Electronics Manufacturing: Monitors solder joints and component defects in industrial hyperspectral imaging in manufacturing lines.

- Agricultural Sorting: Sorts produce by ripeness and nutrition with OEM industrial hyperspectral imaging solutions integrated into conveyor systems.

- Recycling and Waste Management: Classifies plastics and metals for efficient industrial hyperspectral imaging in manufacturing recovery processes.

About Our Company

Sinoseen, a premier China-based camera module manufacturer with over a decade of expertise, specializes in delivering cutting-edge visual solutions for global B2B markets. We offer comprehensive OEM/ODM services for high-resolution industrial hyperspectral imaging systems, leveraging our in-house R&D team to innovate across USB, MIPI, and DVP interfaces. Our one-stop visual application solutions have empowered clients in manufacturing, agriculture, and beyond, with a commitment to quality certified under ISO 9001 and RoHS compliance. As trusted China Industrial hyperspectral imaging suppliers, we prioritize long-term partnerships, providing scalable OEM industrial hyperspectral imaging solutions that drive operational excellence.

Customization Process

- Initial Consultation: Discuss your requirements for compact industrial hyperspectral imaging modules via our expert team.

- Design Prototyping: Develop tailored spectral configurations using CAD simulations.

- Testing and Validation: Conduct on-site trials for industrial hyperspectral imaging for quality control integration.

- Production Scaling: Ramp up to volume manufacturing with full traceability.

- Delivery and Support: Ship customized units with comprehensive documentation for seamless deployment.

Ready to explore wholesale Industrial hyperspectral imaging options? Submit an inquiry for a free customization consultation and unlock efficiency gains in your operations.

Total Cost of Ownership (TCO) Comparison

Our industrial hyperspectral imaging modules offer superior TCO compared to conventional machine vision systems, factoring in setup, operations, and long-term savings.

| Aspect | Industrial Hyperspectral Imaging | Traditional RGB Imaging |

|---|---|---|

| Initial Integration Time | 2-4 weeks | 4-6 weeks |

| Annual Maintenance | Low (modular components) | Medium (frequent calibrations) |

| Efficiency Gains | 40% faster inspections | Baseline |

| Downtime Reduction | Up to 30% | Minimal |

| Scalability | High (OEM flexibility) | Low (hardware limits) |

Compliance Package and Supply Chain Security

Sinoseen ensures full regulatory adherence through our comprehensive compliance package, including CE marking, FCC certification, and REACH compliance for global deployments. Our supply chain security protocol incorporates blockchain-tracked sourcing from vetted Tier-1 suppliers in China, mitigating risks like material shortages or counterfeits. This end-to-end traceability supports Industrial hyperspectral imaging factory standards, guaranteeing 99.9% on-time delivery for B2B orders and fostering trust in international partnerships.

Volume Production Risk Matrix and After-Sales KPIs

We proactively manage production risks to deliver reliable high-resolution industrial hyperspectral imaging systems. Below is our risk matrix, followed by key after-sales performance indicators.

| Risk Factor | Level | Mitigation |

|---|---|---|

| Component Sourcing Delays | Low | Diversified supplier network with 6-month buffer stock |

| Quality Variability | Medium | Automated SPC (Statistical Process Control)2 monitoring |

| Integration Compatibility | Low | Pre-shipment compatibility testing kits |

| Geopolitical Disruptions | Medium | Alternative routing via Southeast Asia hubs |

- Response Time: 24-hour initial support ticket resolution.

- Logistics Speed: 7-14 days from China to major overseas ports (e.g., EU/US via DHL/FedEx).

- Uptime Guarantee: 98% system reliability post-installation.

- Return Rate Target: Under 1% for volume orders.

- Customer Satisfaction: Measured via NPS surveys, targeting 85+ score.

Frequently Asked Questions by Buyers

1. What makes Sinoseen's industrial hyperspectral imaging modules suitable for OEM integration?

Our OEM industrial hyperspectral imaging solutions feature modular designs with standard interfaces, allowing easy embedding into your systems while supporting custom spectral tuning for specific wavelengths.

2. How does industrial hyperspectral imaging improve quality control in manufacturing?

Industrial hyperspectral imaging for quality control provides molecular-level detection, identifying subtle defects like chemical impurities that RGB systems miss, boosting yield rates by 25-35%.

3. Can these modules be customized for high-volume production?

Yes, our compact industrial hyperspectral imaging modules scale from prototypes to thousands of units, with full traceability and compliance for wholesale Industrial hyperspectral imaging needs.

4. What are common challenges in adopting industrial hyperspectral imaging, and how does Sinoseen address them?

Challenges include data processing overload and integration complexity. We mitigate this with edge AI preprocessing and dedicated support, reducing setup hurdles for industrial hyperspectral imaging in manufacturing.

5. How secure is your supply chain for international deliveries?

Our blockchain-secured chain ensures tamper-proof tracking, with expedited shipping from China ensuring arrival in 7-14 days to overseas destinations, minimizing disruptions for time-sensitive B2B projects.

Notes and References

- 1 VNIR: Visible and Near-Infrared spectrum, commonly used in hyperspectral systems for material differentiation.

- 2 SPC: Statistical Process Control, a method for monitoring production variability to maintain quality standards.

Industry Challenges and Solutions:

- Challenge: Spectral data overload in real-time applications. Solution: Deploy our embedded GPU acceleration for 50% faster processing without external servers.

- Challenge: Calibration drift in harsh environments. Solution: Auto-calibration algorithms recalibrate every 1000 frames, ensuring consistent accuracy.

- Challenge: High initial learning curve for operators. Solution: Included training modules and SDKs for seamless adoption in industrial hyperspectral imaging workflows.

References: Market data sourced from industry reports on hyperspectral imaging growth and applications.

EN

EN

AR

AR

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

SR

SR

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

MS

MS

IS

IS

AZ

AZ

UR

UR

BN

BN

HA

HA

LO

LO

MR

MR

MN

MN

PA

PA

MY

MY

SD

SD