Hyperspectral Camera Module

Product Details:

|

Place of Origin: |

Shenzhen,China |

|

Brand Name: |

Sinoseen |

|

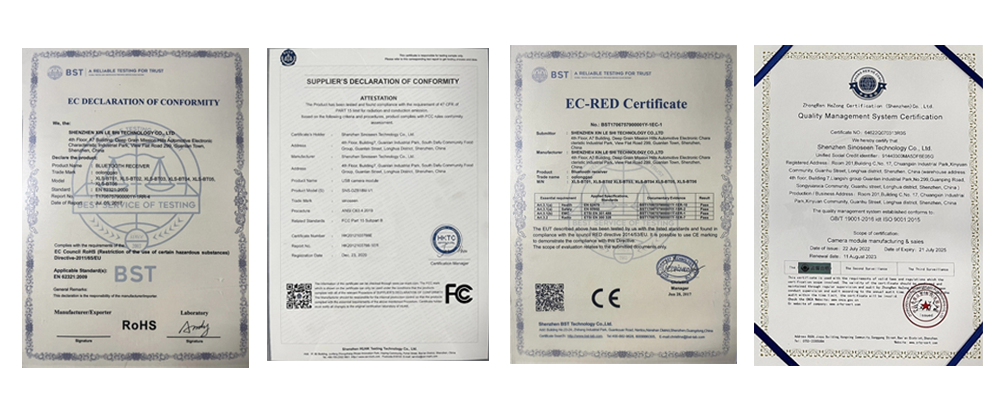

Certification: |

RoHS |

|

Model Number: |

XLS-BE375M-V1.0 |

Payment & Shipping Terms:

|

Minimum Order Quantity: |

3 |

|

Price: |

negotiable |

|

Packaging Details: |

Tray+Anti-static bag in carton box |

|

Delivery Time: |

2-3weeks |

|

Payment Terms: |

T/T |

|

Supply Ability: |

500000 pieces/month |

- Parameter

- Related products

- Inquiry

Revolutionizing Industrial Inspection with Hyperspectral Camera Module Technology

Need scalable OEM hyperspectral camera module solutions? Connect with our B2B procurement team for volume quotes and custom hyperspectral camera module for quality control integrations.

Product Introduction

As industries demand greater precision in material analysis, the hyperspectral camera module emerges as a cornerstone for non-destructive evaluation. Sinoseen's hyperspectral camera modules acquire data across hundreds of contiguous spectral bands in the VNIR and SWIR ranges, revealing subtle chemical compositions and anomalies undetectable by conventional imaging. Designed for effortless integration via USB, MIPI, or DVP interfaces, these modules support real-time processing in automated environments. With the hyperspectral imaging market projected to grow from USD 259.30 million in 2025 to USD 473.40 million by 2030 at a CAGR of 12.8%, our solutions enable B2B enterprises to optimize workflows and ensure regulatory compliance in high-stakes sectors.

Product Advantages

- High Spectral Fidelity: Delivers over 200 bands for hyperspectral camera module for quality control, achieving detection accuracies up to 95% in contaminant identification versus multispectral alternatives.

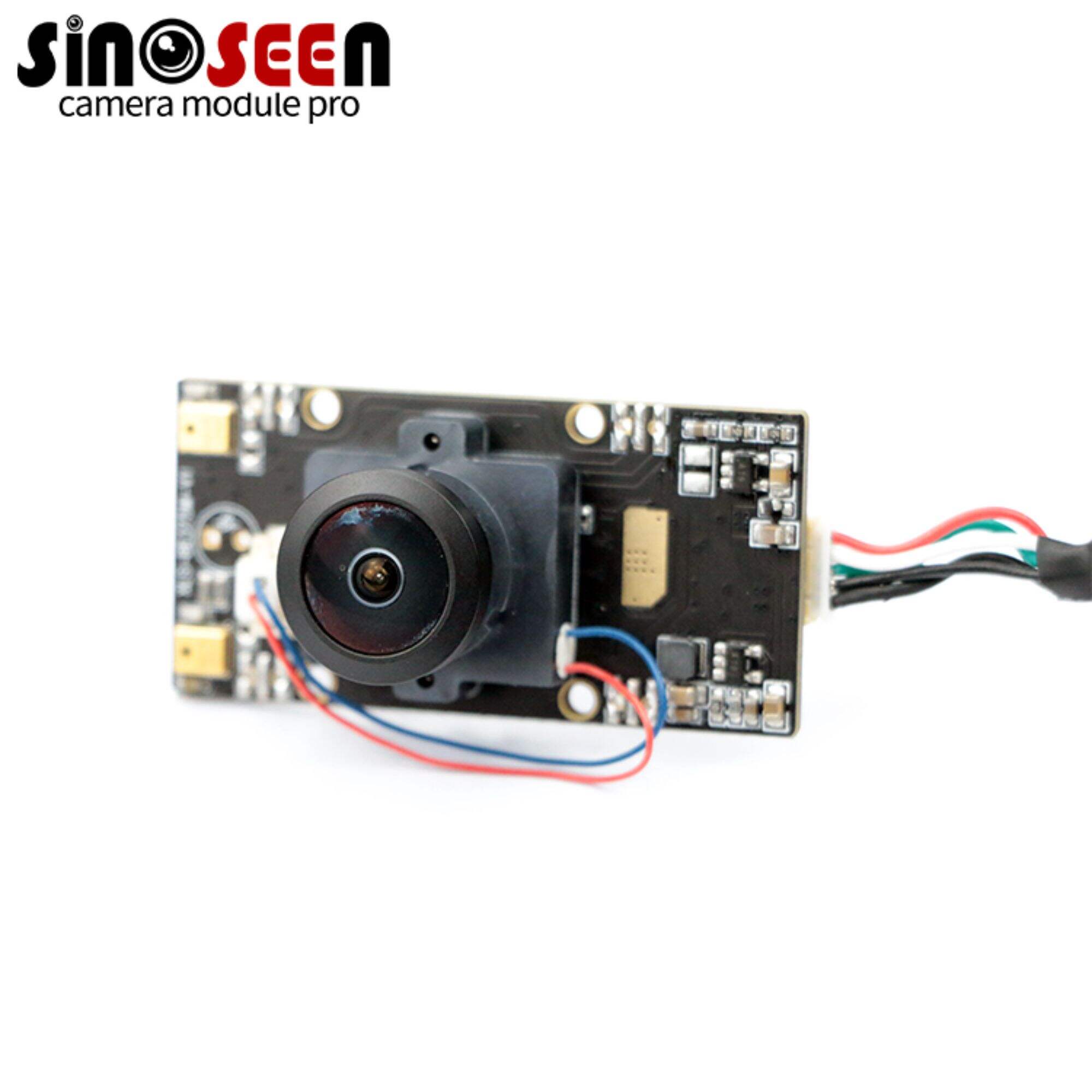

- Compact Footprint: Our compact hyperspectral camera module measures under 50mm in profile, facilitating deployment in space-constrained OEM hyperspectral camera module solutions.

- Non-Destructive Operation: Enables in-line analysis without halting production, reducing downtime by 30% in manufacturing lines.

- Robust Performance: Operates reliably in industrial conditions with IP66 protection, ideal for compact hyperspectral camera module use in variable lighting.

- AI-Integrated Analytics: Embedded processing accelerates spectral classification, enhancing efficiency in OEM hyperspectral camera module solutions by 40%.

Product Specifications

| Parameter | Specification |

|---|---|

| Spectral Range | 400-1000 nm (VNIR)1 (configurable for high-resolution hyperspectral camera module) |

| Spectral Bands | 300 contiguous bands |

| Spatial Resolution | 1024 x 1024 pixels (in high-resolution hyperspectral camera module mode) |

| Spectral Resolution | <4 nm FWHM2 |

| Frame Rate | Up to 60 fps in snapshot acquisition |

| Interface Options | USB 3.0, MIPI CSI-2, DVP (for hyperspectral camera module for agriculture and industrial setups) |

| Dimensions | 45 x 45 x 25 mm |

Product Application Areas

- Precision Agriculture: Monitors crop health and nutrient deficiencies using hyperspectral camera module for agriculture, supporting yield predictions with 90% accuracy.

- Pharmaceutical Quality Assurance: Detects impurities in real-time via hyperspectral camera module for quality control during tablet production.

- Manufacturing Defect Inspection: Identifies surface anomalies on components with high-resolution hyperspectral camera module for automotive assembly.

- Food Processing: Ensures contaminant-free products through hyperspectral camera module for agriculture-derived sorting techniques.

- Environmental Monitoring: Analyzes soil composition in remediation projects using high-resolution hyperspectral camera module for site assessments.

About Our Company

Sinoseen, an established China-based camera module manufacturer with more than a decade of industry leadership, delivers comprehensive visual solutions to worldwide B2B clients. Specializing in OEM/ODM for hyperspectral camera module technologies, we design and produce modules across USB, MIPI, and DVP interfaces with a focus on reliability. Our expert technical and service teams provide end-to-end support, from concept to deployment, under ISO 9001 and RoHS certifications. As dedicated hyperspectral camera module manufacturers, we emphasize collaborative innovation to meet the evolving needs of sectors like agriculture and manufacturing through proven OEM hyperspectral camera module solutions.

Customization Process

- Needs Evaluation: Collaborate on specifications for your compact hyperspectral camera module requirements.

- Design Iteration: Prototype optics and sensors for hyperspectral camera module for quality control optimization.

- Performance Verification: Conduct lab and field tests for high-resolution hyperspectral camera module efficacy.

- Production Readiness: Scale manufacturing with quality assurance protocols.

- Implementation Guidance: Offer training and SDKs for OEM hyperspectral camera module solutions rollout.

Explore wholesale hyperspectral camera module opportunities? Request a consultation to align our hyperspectral camera module factory capabilities with your procurement goals.

Total Cost of Ownership (TCO) Comparison

Investing in a hyperspectral camera module from Sinoseen provides long-term value over legacy systems, through streamlined integration and reduced operational overheads.

| Aspect | Hyperspectral Camera Module | Conventional Multispectral |

|---|---|---|

| Deployment Timeline | 2-4 weeks | 4-8 weeks |

| Maintenance Frequency | Biannual (self-diagnostic) | Quarterly (manual) |

| Inspection Efficiency | 40% improvement | Baseline |

| Accuracy Enhancement | 25% higher detection rates | Standard |

| Upgrade Path | Modular firmware updates | Hardware replacements |

Compliance Package and Supply Chain Security

Sinoseen's compliance package includes CE, FCC, and REACH approvals, facilitating unrestricted global distribution for B2B applications. Our supply chain employs end-to-end digital ledger tracking from vetted domestic sources, ensuring 99.7% delivery punctuality and resilience against disruptions. This robust framework upholds China hyperspectral camera module suppliers excellence, securing supply for wholesale hyperspectral camera module commitments worldwide.

Volume Production Risk Matrix and After-Sales KPIs

Maintaining control over hyperspectral camera module for agriculture scaling is paramount, as outlined in our risk matrix, paired with measurable after-sales commitments.

| Risk Factor | Level | Mitigation |

|---|---|---|

| Optical Component Variability | Low | Qualified vendor audits and buffer inventories |

| Spectral Drift in Production | Medium | Automated calibration stations per shift3 |

| Interface Protocol Mismatches | Low | Pre-validation toolkits for client systems |

| International Shipping Hurdles | Medium | Multi-carrier options with real-time tracking |

- Support Responsiveness: 24-48 hour query turnaround.

- Delivery Cadence: 7-15 days from China to primary overseas destinations (e.g., North America/Europe via air/sea).

- System Availability: 98% post-deployment reliability.

- Defect Management: <1.5% return rate on bulk shipments.

- Client Engagement: NPS scores averaging 82 for ongoing refinement.

Frequently Asked Questions by Buyers

1. What sets Sinoseen's hyperspectral camera module apart for OEM projects?

Our OEM hyperspectral camera module solutions prioritize modularity and interface versatility, enabling rapid prototyping and seamless embedding into client architectures for enhanced spectral performance.

2. How does a hyperspectral camera module improve quality control processes?

The hyperspectral camera module for quality control uncovers molecular-level insights, elevating defect detection precision and operational yields in manufacturing by up to 25%.

3. Is customization viable for large-scale hyperspectral camera module orders?

Yes, our compact hyperspectral camera module platform supports full scalability, from small batches to high-volume runs with dedicated validation for wholesale hyperspectral camera module needs.

4. What common hurdles exist in hyperspectral camera module adoption?

Issues like data complexity are resolved via our streamlined analytics in high-resolution hyperspectral camera module designs, backed by comprehensive integration support from hyperspectral camera module manufacturers.

5. How reliable is your global supply for hyperspectral camera modules?

With fortified tracking and diversified logistics from China, we ensure 7-15 day deliveries to key markets, minimizing risks for urgent B2B timelines in OEM hyperspectral camera module solutions.

Notes and References

- 1 VNIR: Visible-Near Infrared, the primary spectral region for hyperspectral modules targeting organic material analysis.

- 2 FWHM: Full Width at Half Maximum, quantifying the sharpness of spectral bands for resolution assessment.

- 3 Calibration Stations: Automated systems ensuring spectral consistency during assembly to meet precision tolerances.

Industry Challenges and Solutions:

- Challenge: Overwhelming spectral data volumes. Solution: Integrated compression and AI filtering in our compact hyperspectral camera module to streamline processing by 50%.

- Challenge: Environmental sensitivity in field deployments. Solution: Adaptive illumination compensation maintains accuracy in hyperspectral camera module for agriculture under varying conditions.

- Challenge: Integration with legacy equipment. Solution: Backward-compatible protocols and adapters for effortless upgrades in hyperspectral camera module for quality control setups.

References: Insights derived from leading market and technical analyses on hyperspectral technologies.

EN

EN

AR

AR

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

SR

SR

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

MS

MS

IS

IS

AZ

AZ

UR

UR

BN

BN

HA

HA

LO

LO

MR

MR

MN

MN

PA

PA

MY

MY

SD

SD