Compact Hyperspectral Camera Modules

Product Details:

|

Place of Origin: |

Shenzhen,China |

|

Brand Name: |

Sinoseen |

|

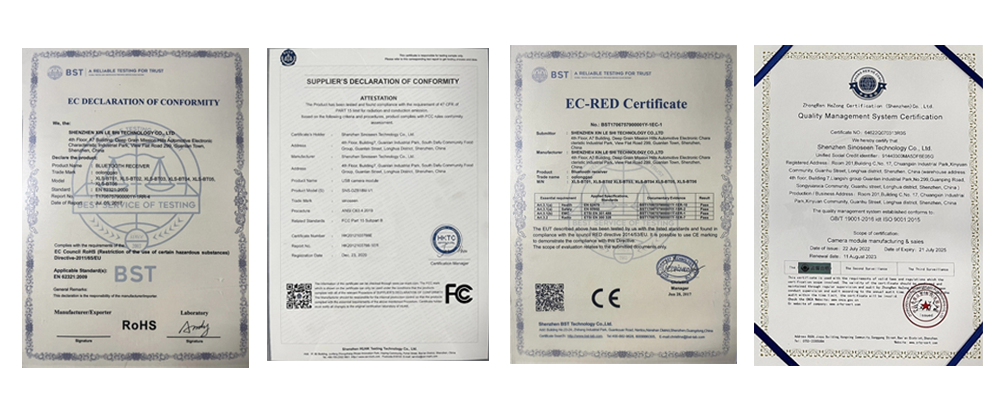

Certification: |

RoHS |

|

Model Number: |

XLS-BE375M-V1.0 |

Payment & Shipping Terms:

|

Minimum Order Quantity: |

3 |

|

Price: |

negotiable |

|

Packaging Details: |

Tray+Anti-static bag in carton box |

|

Delivery Time: |

2-3weeks |

|

Payment Terms: |

T/T |

|

Supply Ability: |

500000 pieces/month |

- Parameter

- Related products

- Inquiry

Innovative Compact Hyperspectral Camera for Seamless Industrial Integration

Searching for trusted OEM compact hyperspectral camera modules? Our B2B specialists are ready to guide you on bulk sourcing and customized compact hyperspectral camera for industrial inspection setups.

Product Introduction

In an era where precision and portability define industrial innovation, the compact hyperspectral camera represents a pivotal advancement in spectral imaging technology. Sinoseen's compact hyperspectral camera modules capture extensive spectral data across the VNIR range, enabling detailed material characterization in a form factor optimized for embedded applications. Supporting interfaces such as USB, MIPI, and DVP, these modules facilitate rapid deployment in dynamic environments. The global hyperspectral imaging market is anticipated to expand from USD 259.3 million in 2025 to USD 602.2 million by 2032, at a CAGR of 12.8%, underscoring the rising adoption of such compact solutions in quality-driven industries.

Product Advantages

- Ultra-Portable Design: Weighing under 200g, our compact hyperspectral camera for UAV applications ensures effortless mounting on drones or robotic arms without performance trade-offs.

- Superior Spectral Coverage: Over 200 bands for high-resolution compact hyperspectral camera analysis, delivering 95% accuracy in anomaly detection compared to multispectral systems.

- Real-Time Capabilities: Snapshot imaging at 30 fps supports compact hyperspectral camera for industrial inspection, minimizing latency in high-speed production lines.

- Enhanced Durability: Ruggedized for IP65 conditions, ideal for portable compact hyperspectral camera solutions in field-based compact hyperspectral camera for UAV applications.

- Flexible OEM Compatibility: Tailored OEM compact hyperspectral camera modules integrate seamlessly, boosting ROI through reduced customization lead times.

Product Specifications

| Parameter | Specification |

|---|---|

| Spectral Range | 400-1000 nm (VNIR)1 (for high-resolution compact hyperspectral camera) |

| Spectral Bands | 270 contiguous bands |

| Spatial Resolution | 1024 x 512 pixels |

| Spectral Resolution | <5 nm FWHM2 |

| Frame Rate | Up to 60 fps in snapshot mode |

| Interface Options | USB 3.0, MIPI CSI-2, DVP (suited for OEM compact hyperspectral camera modules) |

| Dimensions | 30 x 30 x 50 mm |

Product Application Areas

- Aerial Surveillance: Enables crop monitoring via compact hyperspectral camera for UAV applications, detecting stress indicators with 90% precision.

- Manufacturing Quality Check: Inspects defects on assembly lines using compact hyperspectral camera for industrial inspection for non-contact verification.

- Pharmaceutical Analysis: Verifies compound purity with high-resolution compact hyperspectral camera in controlled environments.

- Food Processing: Sorts contaminants through portable compact hyperspectral camera solutions integrated into conveyors.

- Environmental Assessment: Maps pollution via portable compact hyperspectral camera solutions in remote compact hyperspectral camera for UAV applications.

About Our Company

Sinoseen, a distinguished China camera module manufacturer with over ten years of proven expertise, serves global B2B clients with advanced visual solutions. We specialize in OEM/ODM for compact hyperspectral camera technologies, encompassing design and fabrication of modules with USB, MIPI, and DVP connectivity. Our proficient technical and service teams deliver holistic visual application support, adhering to ISO 9001 and RoHS standards. As reliable China compact hyperspectral camera suppliers, we cultivate strategic alliances via innovative OEM compact hyperspectral camera modules that elevate client performance across diverse sectors.

Customization Process

- Consultation Phase: Align on needs for high-resolution compact hyperspectral camera via detailed briefings.

- Prototyping: Fabricate initial units for compact hyperspectral camera for industrial inspection evaluation.

- Testing Protocol: Validate performance in simulated portable compact hyperspectral camera solutions scenarios.

- Scaling Production: Implement volume runs with stringent controls.

- Final Handover: Supply documentation and training for OEM compact hyperspectral camera modules deployment.

Considering wholesale compact hyperspectral camera volumes? Initiate contact for a bespoke assessment from our compact hyperspectral camera factory experts.

Total Cost of Ownership (TCO) Comparison

Sinoseen's compact hyperspectral camera yields optimized TCO relative to bulkier spectral systems, via efficient setup and sustained reliability.

| Aspect | Compact Hyperspectral Camera | Traditional Spectral Scanner |

|---|---|---|

| Integration Period | 1-3 weeks | 4-6 weeks |

| Maintenance Cycle | Annual (remote diagnostics) | Bimonthly (on-site) |

| Operational Efficiency | 35% faster scans | Baseline |

| Downtime Mitigation | 20% reduction | Standard |

| Adaptability | High (modular interfaces) | Moderate (fixed setups) |

Compliance Package and Supply Chain Security

Our compliance suite features CE, FCC, and REACH certifications, streamlining B2B regulatory adherence worldwide. Supply chain integrity is maintained through diversified, audited sourcing in China, with blockchain-enabled monitoring for 99.6% traceability. This approach fortifies compact hyperspectral camera factory operations, ensuring dependable fulfillment for wholesale compact hyperspectral camera demands.

Volume Production Risk Matrix and After-Sales KPIs

Strategic oversight of high-resolution compact hyperspectral camera manufacturing is embedded in our processes, as illustrated below, alongside post-sales benchmarks.

| Risk Factor | Level | Mitigation |

|---|---|---|

| Sensor Availability | Low | Strategic stockpiling with dual suppliers |

| Assembly Precision Variance | Medium | AI-assisted quality inspections3 |

| Customization Delays | Low | Parallel prototyping workflows |

| Global Transit Disruptions | Medium | Contingent routing partnerships |

- Query Handling: 36-hour average response.

- Transit Duration: 6-13 days from China to major international hubs (e.g., Asia/EU/US via optimized carriers).

- Performance Assurance: 97.5% uptime in operational settings.

- Quality Threshold: <1% rejection on deliveries.

- Satisfaction Index: NPS of 80+ through periodic evaluations.

Frequently Asked Questions by Buyers

1. How do Sinoseen's compact hyperspectral camera modules support OEM needs?

Our OEM compact hyperspectral camera modules emphasize plug-and-play interfaces and scalable optics, streamlining incorporation into proprietary systems for compact hyperspectral camera for industrial inspection.

2. What advantages does a compact hyperspectral camera offer for UAV operations?

Compact hyperspectral camera for UAV applications provides lightweight spectral data acquisition, enhancing aerial surveys with minimal payload impact and high-fidelity results.

3. Can high-volume production accommodate custom compact hyperspectral camera features?

Certainly, our portable compact hyperspectral camera solutions transition fluidly to scale, with rigorous testing for wholesale compact hyperspectral camera reliability.

4. What are typical challenges with compact hyperspectral camera integration?

Bandwidth constraints are common; we counter this in high-resolution compact hyperspectral camera via efficient data pipelines, supported by China compact hyperspectral camera manufacturers expertise.

5. How does your supply chain guarantee overseas delivery timelines?

Secure, monitored logistics from China yield 6-13 day arrivals to key regions, with buffers for OEM compact hyperspectral camera modules in critical B2B timelines.

Notes and References

- 1 VNIR: Visible and Near-Infrared, a spectral domain (400-1000 nm) essential for detecting organic and inorganic material signatures.

- 2 FWHM: Full Width at Half Maximum, a metric denoting spectral band precision in hyperspectral systems.

- 3 AI-Assisted Inspections: Machine learning algorithms for real-time defect flagging during assembly to uphold uniformity.

Industry Challenges and Solutions:

- Challenge: Size constraints in mobile deployments. Solution: Optimized optics in our compact hyperspectral camera reduce volume by 40% while preserving resolution.

- Challenge: Processing demands of hyperspectral data. Solution: Onboard edge computing in portable compact hyperspectral camera solutions cuts latency for immediate insights.

- Challenge: Calibration in dynamic fields. Solution: Self-adjusting algorithms ensure stability in compact hyperspectral camera for UAV applications across missions.

References: Derived from authoritative industry reports and technical specifications.

EN

EN

AR

AR

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

SR

SR

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

MS

MS

IS

IS

AZ

AZ

UR

UR

BN

BN

HA

HA

LO

LO

MR

MR

MN

MN

PA

PA

MY

MY

SD

SD