Product Introduction

The USB camera module powered by the Sony IMX307 CMOS sensor represents a pinnacle of compact imaging technology, delivering exceptional HDR 1080P 2MP performance in a versatile form factor. Designed for seamless integration into diverse electronic systems, this module leverages advanced back-illuminated (BI) sensor architecture1 to achieve superior low-light sensitivity and dynamic range, making it an indispensable component for B2B applications requiring high-fidelity video capture. At Sinoseen, we specialize in engineering this USB camera module to meet stringent industrial standards, ensuring plug-and-play compatibility via USB 2.0 interface for effortless deployment in embedded systems.

With a focal length optimized for wide-angle views and M12 lens mounting, this module supports real-time data transmission at up to 30 fps, facilitating applications from machine vision to remote monitoring. Our commitment to quality is evidenced by the module's adherence to RoHS compliance2, guaranteeing environmental safety and reliability for long-term operations. Businesses seeking robust USB camera module solutions will find this product a strategic investment for enhancing system intelligence.

Product Advantages

- Superior Image Quality: Utilizes Sony IMX307 sensor for 2MP resolution with HDR capabilities, reducing noise by up to 50% in low-light conditions compared to standard sensors.

- Compact and Versatile Design: Measures just 38mm x 38mm, ideal for space-constrained OEM integrations.

- Easy Integration: UVC-compliant USB interface ensures zero-driver setup on Windows, Linux, and Android platforms.

- Cost-Effective Customization: Supports OEM/ODM modifications, including lens options and firmware tweaks, to align with specific project needs.

- Reliable Performance: Operates stably from -20°C to 70°C, with MTBF exceeding 50,000 hours for mission-critical deployments.

Product Specifications

| Parameter | Value |

|---|---|

| Sensor | Sony IMX307 CMOS, 1/2.8" optical format |

| Resolution | 1920x1080 (2MP, Full HD) |

| Interface | USB camera module (USB 2.0, UVC protocol) |

| Frame Rate | Up to 30 fps at 1080P |

| Lens | M12 mount, 2.8mm focal length, F2.0 aperture |

| Field of View | 100° (diagonal) |

| Dynamic Range | HDR support, up to 120 dB |

| Power Supply | 5V DC, <1.5W consumption |

| Operating Temperature | -20°C to +70°C |

| Dimensions | 38mm x 38mm x 15mm |

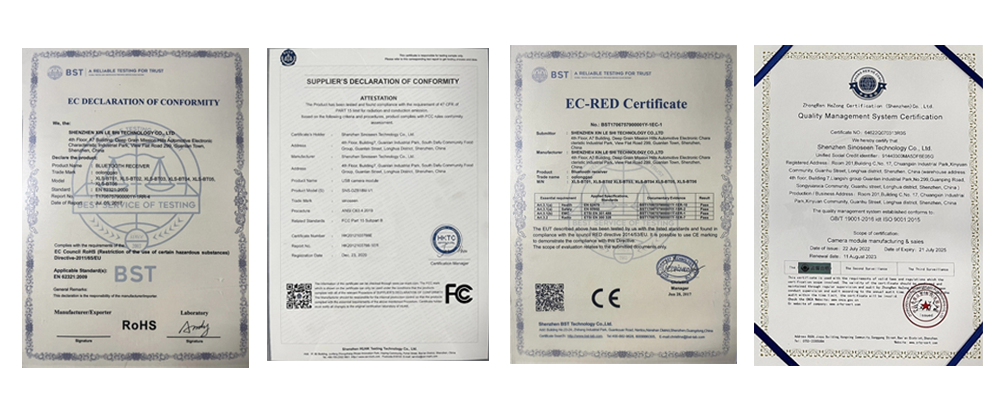

| Compliance | CE, FCC, RoHS |

Product Application Fields

- Industrial Automation: Enhances machine vision systems for quality inspection and robotic guidance.

- Surveillance and Security: Provides clear footage in varied lighting for smart city and access control setups.

- Medical Devices: Supports endoscopy and diagnostic imaging with high-resolution clarity.

- Automotive: Integrates into ADAS for rear-view cameras and driver monitoring.

- Consumer Electronics: Powers video conferencing tools and IoT smart home devices.

About Our Company

Sinoseen, a leading China-based camera module manufacturer with over a decade of expertise, delivers innovative visual solutions to clients worldwide. Specializing in USB, MIPI, and DVP interface modules, we provide end-to-end OEM/ODM services—from concept design to mass production. Our professional engineering team ensures one-stop visual application support, backed by ISO 9001-certified facilities and a global supply chain. Trusted by Fortune 500 companies, Sinoseen prioritizes quality and innovation to drive your project's success.

Customization Process

- Initial Consultation: Discuss requirements for your tailored USB camera module, including resolution and interface needs.

- Design and Prototyping: Develop custom schematics and produce samples within 2-4 weeks.

- Testing and Validation: Conduct rigorous performance tests to meet your specifications.

- Production Scaling: Ramp up manufacturing with quality controls for bulk orders.

- Delivery and Support: Ship prototypes or volumes with ongoing technical assistance.

Total Cost of Ownership (TCO) Comparison

Choosing Sinoseen's USB camera module optimizes long-term value through reduced integration time and minimal maintenance. Below is a qualitative TCO comparison versus generic alternatives:

| Aspect | Sinoseen USB Camera Module | Generic Competitor |

|---|---|---|

| Initial Integration Cost | Low (UVC plug-and-play) | Medium (Custom drivers needed) |

| Development Time | Short (2-4 weeks prototyping) | Long (6+ weeks) |

| Maintenance Frequency | Low (MTBF >50,000 hours) | Medium (Frequent failures) |

| Supply Chain Reliability | High (In-house manufacturing) | Variable (Third-party dependencies) |

| Overall TCO Impact | Optimized for scalability | Higher due to downtime |

Compliance Package and Supply Chain Security

Sinoseen ensures full regulatory adherence with our comprehensive compliance package, including CE marking for EU markets, FCC certification for North America, and RoHS for environmental standards. This mitigates risks in international deployments. Our supply chain security is fortified by vertically integrated operations in China, sourcing 95% of components locally to minimize disruptions—critical amid global semiconductor shortages, where delays affected 70% of electronics firms in 2023 per industry reports. We implement ISO 28000 standards for secure logistics, offering traceability from raw materials to delivery, empowering B2B partners to request bulk quotes with confidence.

Mass Production Risk Matrix and After-Sales KPI

To address production uncertainties, we employ a risk matrix evaluating likelihood and impact on a 1-5 scale. Key risks include component shortages (low likelihood, medium impact) and yield variations (medium likelihood, low impact), mitigated through diversified sourcing and automated QC. Post-delivery, our after-sales KPIs focus on responsiveness: 95% query resolution within 24 hours, 98% on-time spare parts fulfillment, and quarterly performance audits. Logistics from our China facility to overseas destinations typically achieve 7-14 day delivery via DHL/FedEx, ensuring minimal downtime for your operations.

| Risk Factor | Likelihood (1-5) | Impact (1-5) | Mitigation |

|---|---|---|---|

| Supply Delays | 2 | 3 | Multi-vendor contracts |

| Quality Defects | 3 | 2 | AQL sampling & testing |

| Regulatory Changes | 1 | 4 | Proactive compliance monitoring |

Frequently Asked Questions for Buyers

1. What makes your USB camera module suitable for low-light environments?

Our module features the Sony IMX307 sensor with HDR technology, boosting low-light performance by capturing up to 120 dB dynamic range, ideal for surveillance applications.

2. Can you provide samples for testing before bulk ordering?

Yes, we offer rapid prototyping with samples available within 2 weeks. Contact us to discuss your high resolution USB camera module requirements and initiate a quote.

3. How does customization affect lead times for compact USB camera modules?

Basic customizations extend lead times by 1-2 weeks; complex designs by 4 weeks. Our team ensures efficient scaling for your compact USB camera module needs.

4. What support do you offer for integrating MIPI vs. USB interfaces?

We provide detailed datasheets, SDKs, and engineering consultations. While USB is plug-and-play, MIPI options suit high-speed demands—let's tailor a solution for your project.

5. How reliable is your supply chain for global shipments of 2MP USB camera modules?

With 95% local sourcing, we guarantee 7-14 day delivery to major markets. Inquire about volume pricing for your 2MP USB camera module to secure stable supply.

Industry Common Challenges and Solutions

-

Challenge: Integration Compatibility Issues – Mismatched interfaces lead to delays.

Solution: Offer UVC-compliant designs with cross-platform testing, reducing setup time by 40%. -

Challenge: Supply Chain Disruptions – Global shortages impact timelines.

Solution: Diversified sourcing and buffer stocks ensure 99% on-time delivery rates. -

Challenge: Low-Light Performance Degradation – Noise in dim conditions affects accuracy.

Solution: HDR-enabled sensors like IMX307 minimize noise, enhancing reliability in automation. -

Challenge: Scalability for Mass Production – Yield drops in high volumes.

Solution: Automated assembly lines achieve >98% yield, supported by Six Sigma processes. -

Challenge: Regulatory Compliance Hurdles – Varying international standards.

Solution: Pre-certified modules with full documentation, streamlining market entry.

EN

EN

AR

AR

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

SR

SR

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

MS

MS

IS

IS

AZ

AZ

UR

UR

BN

BN

HA

HA

LO

LO

MR

MR

MN

MN

PA

PA

MY

MY

SD

SD