How to Integrate a Small Camera Module into Compact Medical Devices?

Medical device miniaturization continues to revolutionize healthcare, enabling less invasive procedures and improved patient outcomes. When designing compact medical equipment, integrating a small camera module requires careful consideration of space constraints, power consumption, and regulatory compliance. The selection and implementation of these optical components directly impacts device performance, imaging quality, and overall functionality. Engineers must balance multiple technical requirements while ensuring the small camera module meets stringent medical standards. Understanding the integration process helps manufacturers create more effective and reliable diagnostic and therapeutic devices.

Understanding Small Camera Module Specifications for Medical Applications

Critical Technical Parameters

When selecting a small camera module for medical devices, resolution requirements form the foundation of your design decision. Medical applications typically demand high-quality imaging capabilities while maintaining compact form factors. The pixel density and sensor size directly influence the final image quality and the overall device dimensions. Engineers must evaluate whether VGA, HD, or higher resolutions meet their specific diagnostic needs. Power consumption specifications become equally important, as medical devices often operate on battery power for extended periods.

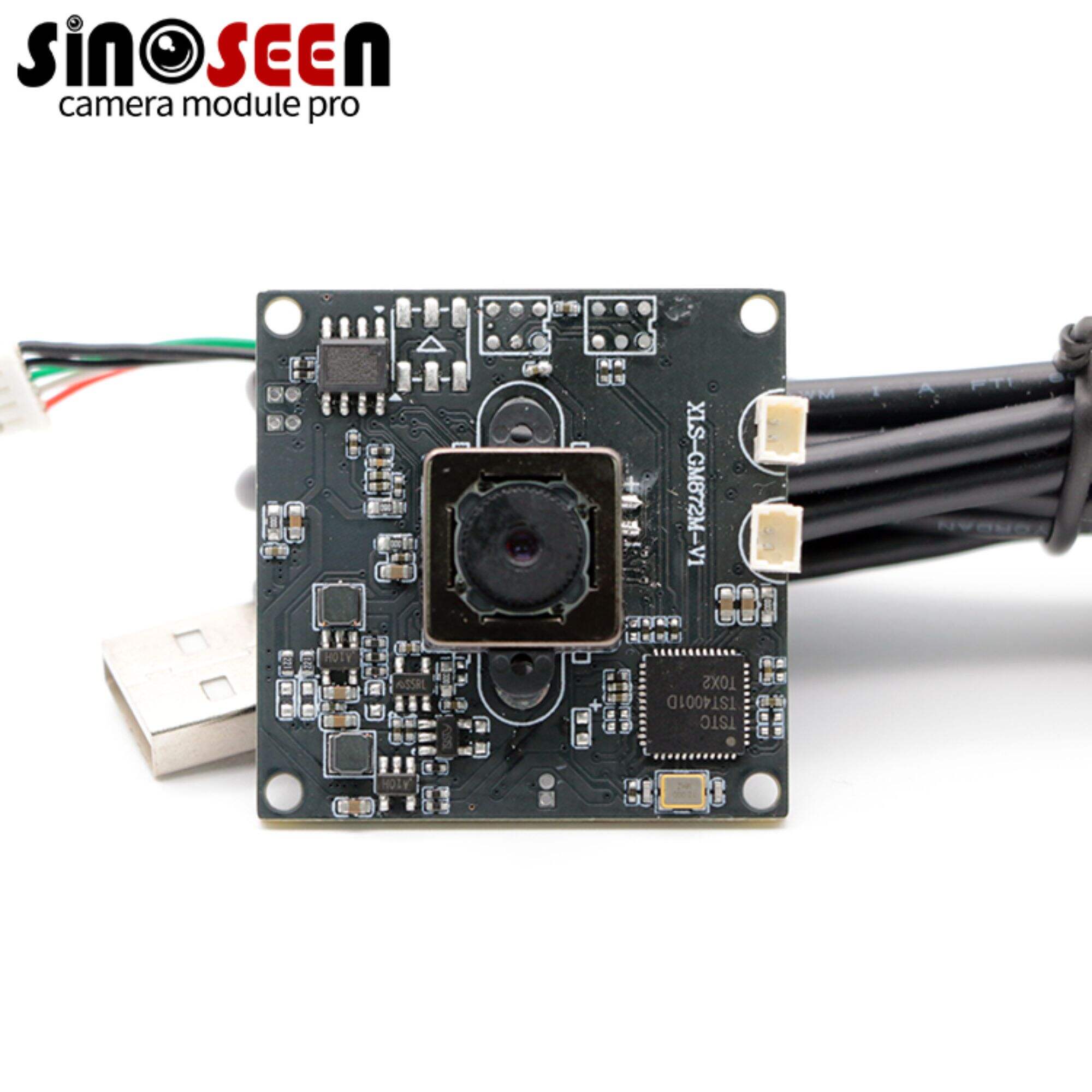

Sensor technology choices significantly impact both performance and integration complexity. CMOS sensors offer excellent low-power operation and easier integration compared to CCD alternatives. The small camera module interface options, including USB, MIPI, or parallel connections, must align with your device's processing capabilities. Frame rate requirements vary depending on whether the device captures still images or requires real-time video streaming. Temperature operating ranges become critical for devices that may encounter sterilization processes or varying environmental conditions.

Size and Form Factor Considerations

Physical dimensions play a crucial role in successful small camera module integration. The module footprint must accommodate the available space within your device housing while leaving room for necessary connections and heat dissipation. Thickness constraints often prove most challenging, particularly in handheld diagnostic tools or wearable medical devices. The lens assembly dimensions can significantly impact the overall device profile and may require custom optical solutions.

Cable and connector configurations affect both the module placement flexibility and the final device size. Flexible flat cables allow for more creative positioning options compared to rigid connections. The small camera module mounting requirements must consider vibration resistance and mechanical stability during normal operation. Engineers should account for assembly tolerances and potential thermal expansion that could affect optical alignment over time.

Design Considerations for Medical Device Integration

Power Management Strategies

Efficient power management extends battery life and reduces heat generation in compact medical devices. The small camera module power consumption varies significantly between active imaging periods and standby modes. Implementing intelligent power cycling can dramatically improve overall device efficiency. Sleep mode configurations allow the camera to remain ready for rapid activation while consuming minimal power during idle periods.

Power supply stability directly affects image quality and sensor performance. Clean power delivery systems prevent noise interference that could degrade imaging capabilities. Voltage regulation becomes particularly important when the device operates across varying battery charge levels. The small camera module may require specific power sequencing during startup and shutdown procedures to prevent damage or operational issues.

Thermal Management Solutions

Heat dissipation challenges increase as device sizes decrease and component densities rise. The small camera module generates heat during operation that must be managed without affecting nearby sensitive components. Thermal design considerations include heat sink placement, airflow patterns, and material selection for optimal heat conduction. Passive cooling solutions often prove more suitable than active cooling in compact medical devices due to space and power constraints.

Temperature sensors can provide feedback for thermal management algorithms that adjust camera performance based on operating conditions. Thermal interface materials improve heat transfer between the camera module and the device housing. The small camera module placement within the device should consider heat sources from other components like processors or LED illumination systems. Thermal modeling during the design phase helps identify potential hot spots and optimize cooling strategies.

Integration Process and Assembly Techniques

Mechanical Integration Methods

Proper mechanical mounting ensures reliable operation throughout the device lifecycle. The small camera module requires secure attachment that maintains optical alignment while accommodating manufacturing tolerances. Mounting techniques range from simple screws to sophisticated alignment fixtures depending on precision requirements. Vibration and shock resistance become particularly important for portable medical devices that experience regular handling.

Assembly processes must consider accessibility for manufacturing and potential service requirements. The camera module positioning affects both optical performance and ease of integration with other device components. Mechanical stress on the module during assembly can damage delicate sensor components or affect focus mechanisms. Quality control procedures should verify proper alignment and mechanical integrity after installation.

Electrical Connection and Signal Integrity

High-speed digital signals from modern camera modules require careful electrical design to maintain signal integrity. The small camera module interface connections must minimize noise and crosstalk that could degrade image quality. Proper impedance matching and signal routing techniques prevent reflection and timing issues. Shielding may be necessary to protect sensitive camera signals from electromagnetic interference generated by other device components.

Ground plane design becomes critical for maintaining clean power and signal references. The camera module ground connections should tie into a solid ground system that minimizes ground loops and noise coupling. Signal trace routing should follow best practices for high-frequency digital design, including appropriate trace widths and via placement. The small camera module connections require robust connectors that maintain reliability over many connection cycles.

Software Integration and Control Systems

Driver Development and Camera Control

Software integration begins with developing appropriate device drivers that interface with the small camera module hardware. Driver development must account for the specific sensor characteristics and timing requirements. Camera control APIs should provide access to essential functions like exposure control, white balance adjustment, and image format selection. Real-time performance requirements may necessitate optimized code paths and efficient memory management.

Image processing capabilities can enhance the raw sensor output to meet medical imaging standards. Basic processing functions include noise reduction, color correction, and geometric distortion compensation. The small camera module driver should support multiple operating modes to accommodate different medical applications. Integration with existing device software architectures requires careful attention to thread safety and resource management.

Image Processing and Enhancement

Medical applications often require specialized image processing algorithms to extract diagnostic information. Edge enhancement algorithms can improve detail visibility in captured images. Noise reduction techniques become particularly important in low-light conditions common in medical environments. The small camera module output may require color space conversions to match display or storage requirements.

Real-time image processing capabilities depend on the available computational resources within the medical device. Hardware acceleration options like dedicated image processors can improve performance while reducing power consumption. Image compression algorithms help manage storage and transmission requirements for captured medical images. Processing pipeline optimization ensures smooth operation without introducing excessive latency.

Testing and Validation Procedures

Optical Performance Verification

Comprehensive testing validates that the integrated small camera module meets medical device requirements. Resolution testing using standardized targets verifies the imaging system achieves specified performance levels. Color accuracy measurements ensure faithful reproduction of medical specimens or patient anatomy. Distortion testing identifies any geometric errors that could affect diagnostic accuracy.

Light sensitivity testing covers the expected operating range for medical environments. The small camera module performance under various illumination conditions must meet clinical requirements. Focus accuracy testing verifies proper operation across the intended working distance range. Environmental testing confirms reliable operation under temperature and humidity conditions typical in medical settings.

Reliability and Durability Assessment

Long-term reliability testing ensures the camera module maintains performance over the device's expected lifespan. Accelerated aging tests simulate years of operation in compressed timeframes. Mechanical stress testing validates the module withstands normal handling and operational forces. The small camera module must demonstrate consistent performance across multiple sterilization cycles if required for the medical application.

Electrical stress testing confirms reliable operation across voltage and temperature ranges. EMC testing verifies the device meets electromagnetic compatibility requirements for medical environments. Drop testing and vibration testing simulate real-world usage conditions. Quality assurance procedures should include statistical sampling and defect tracking to ensure consistent manufacturing quality.

Regulatory Compliance and Standards

Medical Device Certification Requirements

Medical devices incorporating camera modules must comply with relevant regulatory standards depending on their intended use and classification. FDA regulations in the United States and CE marking requirements in Europe establish specific compliance pathways. The small camera module integration must not compromise the overall device's safety or effectiveness. Documentation requirements include detailed design histories and risk analysis reports.

Biocompatibility testing may be required if the camera module comes into contact with patients or bodily fluids. Software validation procedures must demonstrate that the camera control systems operate safely and reliably. Clinical testing requirements vary based on the device's intended medical application and risk classification. The small camera module specifications must support the overall device's regulatory submission requirements.

Quality Management System Integration

ISO 13485 quality management systems provide the framework for medical device manufacturing control. The camera module supplier evaluation process must verify their quality systems meet medical device requirements. Traceability systems track individual camera modules from receipt through final device assembly. Change control procedures ensure any modifications to the small camera module or integration process receive appropriate review and approval.

Risk management processes evaluate potential hazards associated with camera module integration and operation. Design controls ensure that user needs translate into appropriate camera specifications and integration requirements. Corrective and preventive action procedures address any quality issues discovered during manufacturing or field use. The small camera module integration must support the overall device quality system requirements and audit procedures.

FAQ

What factors determine the appropriate resolution for a medical device small camera module

The required resolution depends on the specific medical application and diagnostic requirements. Dermatology applications might need higher resolution for detailed skin examination, while endoscopy procedures may prioritize frame rate over maximum resolution. Consider the display capabilities of your device and the smallest details that clinicians need to observe. Higher resolution modules typically consume more power and generate more heat, which may impact battery life and thermal management in compact devices.

How do power consumption requirements affect small camera module selection

Power consumption directly impacts battery life in portable medical devices. Compare active imaging power consumption with standby power requirements to understand the total energy budget. Sleep mode capabilities allow the camera to remain ready for quick activation while minimizing power drain during idle periods. Consider implementing power management algorithms that adjust camera performance based on battery charge levels to extend operational time between charges.

What environmental considerations are important for medical device camera integration

Medical environments present unique challenges including temperature variations, humidity, and potential exposure to cleaning chemicals. The small camera module must operate reliably across the expected temperature range and survive sterilization processes if required. Consider condensation prevention in humid environments and ensure all materials are compatible with medical cleaning protocols. Environmental sealing may be necessary to protect internal components from moisture or contaminants.

How can manufacturers ensure reliable long-term performance of integrated camera modules

Implement comprehensive testing procedures including accelerated aging tests and environmental stress screening. Establish quality control processes that verify optical alignment and electrical connections during manufacturing. Design mechanical mounting systems that maintain camera stability over time while accommodating thermal expansion. Regular performance validation throughout the manufacturing process helps identify potential issues before devices reach end users, ensuring consistent quality and reliability in medical applications.

EN

EN

AR

AR

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

SR

SR

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

MS

MS

IS

IS

AZ

AZ

UR

UR

BN

BN

HA

HA

LO

LO

MR

MR

MN

MN

PA

PA

MY

MY

SD

SD