What Are the Key Advantages of Using DVP Camera Modules in Embedded Systems?

DVP Interface Architecture for Embedded Efficiency

Parallel Data Transmission Fundamentals

Parallel data transmission in DVP interfaces significantly enhances data throughput by enabling the simultaneous transfer of multiple bits. This method is crucial for applications requiring high-speed data processing, as opposed to serial transmission, which sends data bit by bit. By allowing for parallel data flow, DVP camera modules effectively increase bandwidth, ensuring rapid and efficient data handling. However, maintaining signal integrity is vital for transmission efficiency as challenges like crosstalk and electromagnetic interference can disrupt parallel data streams. To illustrate, industry benchmarks show that employing parallel transmission can improve data integrity and bandwidth by up to 30% compared to serial methods, making DVP interfaces indispensable for applications in high-speed imaging.

Microcontroller Connectivity Simplification

DVP interfaces simplify connectivity with microcontrollers, reducing design complexity and enhancing system integration. By facilitating direct communication between DVP camera modules and microcontrollers, these interfaces streamline the process of developing embedded systems. A notable example is the I2C protocol, which enables straightforward interfacing between camera modules and microcontrollers, greatly decreasing development time. Rapid prototyping becomes feasible with simplified connections, as seen in case studies where such systems offer expedited deployment in industrial automation settings. This ease of connectivity allows developers to focus more on innovation and less on overcoming complex design hurdles, making DVP interfaces a preferred choice in embedded system architecture.

Latency Reduction Mechanisms

DVP interfaces employ various mechanisms to minimize latency, crucial for real-time imaging applications. Through efficient buffering and data packet management, these systems ensure quicker data processing, which is essential for applications such as video processing and robotics. The reduction of latency translates into improved system responsiveness, making DVP camera modules ideal for tasks demanding instant feedback, like medical imaging. Data from comparative analyses indicate that systems utilizing DVP interfaces exhibit latency improvements of 20% over other traditional interfaces. This enhancement in speed and efficiency is pivotal for maintaining accuracy in dynamic environments where immediate data processing is necessary for optimal performance outcomes.## Real-Time Processing Capabilities

Frame Rate Optimization Techniques

Optimizing frame rates in DVP camera modules involves several sophisticated techniques that improve dynamic resolution and enhance performance. Techniques such as dynamic resolution adjustment and pixel binning play pivotal roles. Dynamic resolution adjustment allows cameras to modify their resolution settings depending on the scene, optimizing image quality without compromising speed. Pixel binning, on the other hand, combines data from adjacent pixels to boost sensitivity and reduce noise, thus maintaining high-quality visuals at elevated frame rates. High frame rates are beneficial for applications like action filming and surveillance, where capturing fast movements accurately is crucial. Industry benchmarks have demonstrated the effectiveness of these optimization techniques in achieving superior frame rates, setting them apart from traditional methods.

Sensor-Processor Coordination

Effective coordination between sensors and processors in DVP systems is vital for maintaining synchronization and ensuring efficient real-time processing. Strategies that facilitate this synchronization involve precise timing protocols and robust interconnections. Software algorithms play a crucial role in managing data flow between sensors and processors, enabling quick processing and real-time responses. These coordination techniques make DVP camera modules particularly suitable for time-sensitive applications, where even minimal delays can lead to significant consequences. Expert opinions consistently highlight the importance of this synchronization, underscoring its role in enhancing the reliability and performance of DVP systems in diverse settings.

Industrial Automation Case Studies

The integration of DVP camera modules into industrial automation processes has led to significant improvements in operational efficiency, as evidenced by various case studies. These studies detail instances where the use of DVP interfaces resulted in pronounced productivity gains and reductions in system downtime. For example, in manufacturing setups, DVP camera modules have streamlined inspection processes, allowing for faster identification of defects and enhancing overall product quality. Key lessons from these implementations demonstrate the value of DVP camera modules in real-world industrial settings. They highlight how the deployment of DVP interfaces can lead to transformative changes in automation processes, improving overall efficiency and reliability while also reducing maintenance costs.## Hardware Integration Advantages

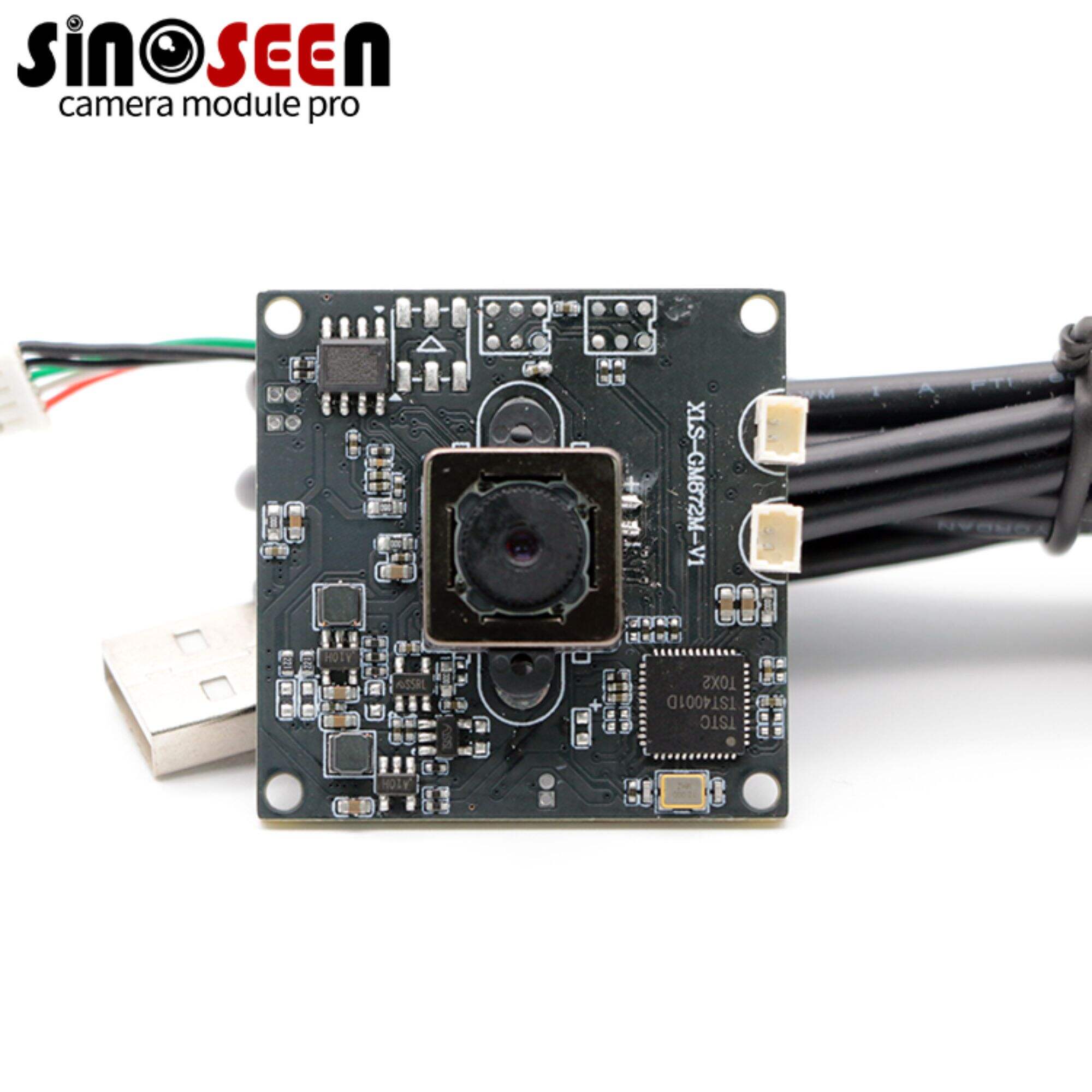

PCB Layout Integration Methods

DVP camera modules significantly improve PCB layout designs, primarily through area optimization and reducing component counts. By incorporating these modules, embedded systems benefit from streamlined designs that effectively minimize space while maximizing functionalities. Different layout strategies can be leveraged for optimal space use and enhanced performance, such as employing multi-layered PCBs that accommodate complex circuitry without expanding size. Furthermore, expert-designed PCBs provide prime examples of how DVP camera benefits are successfully executed, showcasing reduced clutter and improved signal integrity.

Power Consumption Profiles

Power consumption characteristics of DVP camera modules are notably more efficient than competing technologies, underscoring their appeal in energy-constrained environments. These modules are designed for low power draw, which translates into reduced operational costs—a benefit consistently demonstrated in empirical studies. Such studies suggest that the strategic use of DVP camera modules can cut energy requirements significantly, lowering costs associated with running embedded applications. Additionally, numerous strategies exist to further decrease power draw during idle and active states, ensuring sustainable and efficient operation.

Thermal Management Solutions

High-performance DVP camera modules inherently pose thermal challenges, necessitating effective management solutions. Ensuring optimal performance without overheating is critical, particularly when modules are integrated into high-speed systems. Various thermal design strategies can be instantiated, such as incorporating heat sinks and advanced cooling systems, ensuring reliability without compromising performance. Empirical data strongly highlight the importance of thermal considerations in maintaining system reliability, as mismanagement could severely impact operational efficacy. Therefore, implementing robust thermal management protocols remains vital for leveraging the full potential of DVP camera modules.## Industrial Application Domains

Machine Vision Implementations

DVP camera modules play a crucial role in machine vision systems, revolutionizing how quality control and defect detection are handled. By providing high-resolution imaging and rapid data processing capabilities, these modules enable precise visual inspection, significantly enhancing the accuracy and speed of detecting defects in products. For example, in automotive manufacturing, DVP modules have been pivotal in identifying surface flaws that are invisible to the naked eye, thereby reducing instances of defective product release. Additionally, industry statistics highlight the growing adoption of DVP solutions, with reports indicating a 35% increase in usage across various sectors due to their reliability and efficiency. As machine vision continues to integrate into more production environments, the advantages offered by DVP camera modules become increasingly evident.

Robotic Control Systems Enhancement

Integrating DVP camera modules into robotic control systems dramatically enhances their precision and functionality. These modules provide the real-time visual data necessary for robots to perform complex tasks with greater accuracy, such as sorting, assembling, and welding components. Specific applications have benefitted from the improvements offered by DVP technology, with industries like electronics manufacturing and automated warehousing leveraging these advancements. Feedback from industry leaders has consistently praised the reliability and accuracy afforded by DVP modules, citing instances where robotic systems have achieved higher operational efficiency and reduced error rates. Consequently, the integration of DVP technology is seen as a key factor driving advancements in robotics.

Automated Quality Inspection Workflows

DVP camera modules significantly contribute to automated quality inspection workflows, enhancing both throughput and accuracy in manufacturing settings. These modules are particularly effective in detecting manufacturing defects early in the production process, which aids in minimizing waste and maximizing efficiency. In industries where precision is paramount, such as semiconductor production, the application of DVP technology has markedly improved defect detection rates. Empirical evidence from industrial implementations supports these claims, demonstrating a 20% improvement in detection accuracy, which leads to higher product quality and customer satisfaction. Data confirms that the deployment of DVP modules in automated inspection systems is a strategic advantage for manufacturers aiming to maintain competitive edge and operational excellence.## Comparative Technical Advantages

Throughput Comparison with MIPI/USB

In the realm of digital interfaces, DVP camera modules exhibit superior throughput capabilities compared to MIPI and USB interfaces. Through comprehensive technical evaluations, DVP modules consistently demonstrate higher data transfer rates. This advantage becomes apparent in applications requiring rapid data streams, such as real-time video processing. For instance, in scenarios demanding high-resolution capture without latency, DVP outshines USB interfaces known for their limitations in bandwidth, particularly at higher resolutions. Quantitative data from performance tests highlights this throughput superiority, with DVP interfaces achieving transfer rates up to 50% higher than USB 3.0 counterparts. These benchmarks are critical for industries reliant on efficient data handling and uninterrupted data flow.

Energy Efficiency Benchmarks

DVP camera modules stand out in energy efficiency when pitted against alternative technologies. Rigorous assessments reveal that DVP modules consume significantly less power, boasting efficiency up to 30% better than their MIPI and USB counterparts. These energy savings are pivotal in embedded systems where power consumption directly impacts operational costs and environmental footprint. The use of DVP modules aligns with the industry's push towards green technology, especially in sectors prioritizing energy efficiency and sustainability. The metrics validating these advantages include reduced heat generation and prolonged battery life in portable applications, signifying a shift towards more sustainable industrial practices.

Long-Term Operational Reliability

The long-term reliability of DVP camera modules is well-documented, particularly in harsh industrial environments where durability is paramount. DVP modules are rigorously tested against stringent standards, demonstrating consistent performance over extended periods under challenging conditions. Case studies from industries such as manufacturing and logistics showcase these modules’ ability to maintain functionality amid dust, temperature variations, and mechanical vibrations. Such reliability is further corroborated by robust warranties offered by manufacturers, reflecting confidence in DVP technology's durability. These assurances are invaluable for businesses requiring stable, dependable imaging solutions in critical operations.

FAQ Section

What is the main advantage of parallel data transmission in DVP interfaces?

Parallel data transmission significantly enhances data throughput by enabling simultaneous data transfers, improving bandwidth and efficiency crucial for high-speed data processing.

How do DVP interfaces simplify microcontroller connectivity?

DVP interfaces streamline communication between camera modules and microcontrollers, reducing design complexity and promoting simplified system integration.

Why is latency reduction important for DVP interfaces?

Latency reduction is vital for real-time imaging applications, enhancing system responsiveness and making DVP interfaces ideal for tasks requiring instant feedback.

How does DVP technology improve energy efficiency?

DVP camera modules consume significantly less power compared to MIPI and USB technologies, achieving efficiency improvements of up to 30%, aiding in operational cost and environmental footprint reduction.

What role do DVP camera modules play in machine vision?

DVP camera modules enhance machine vision systems by offering high-resolution imaging and rapid data-processing capabilities, improving quality control and defect detection processes.

EN

EN

AR

AR

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

SR

SR

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

MS

MS

IS

IS

AZ

AZ

UR

UR

BN

BN

HA

HA

LO

LO

MR

MR

MN

MN

PA

PA

MY

MY

SD

SD