What is an IR-cut filter?and How does an IR-cut filter work?

In recent years, the demand for day and night video surveillance has increased significantly. As we all know, camera modules are like the eyes of a vision system. They need to capture real-time images like the human eye, and their sensors can also detect near-infrared light, which is invisible to the human eye. However, the physical properties of image sensors make them particularly sensitive to infrared light, which can cause color distortion in images recorded during the day.

As a consultant specializing in camera modules, this article will provide an in-depth understanding of IR-cut filters. We will explore how they work, why they are so important, and how they can be used to address issues encountered during daytime switching in embedded vision systems.

What is infrared?

Infrared light is a type of electromagnetic wave invisible to the human eye, with a wavelength longer than visible light. Generally, the human eye can see light with wavelengths between 320nm and 760nm. Infrared light, on the other hand, spans the 700nm to 1000nm wavelength range in the electromagnetic spectrum. In our daily lives, devices like remote controls and thermal imagers utilize the properties of infrared light.

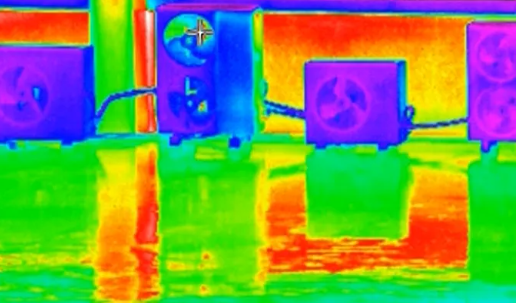

Although invisible to the human eye, image sensors such as CMOS and CCD sensors can capture it. This sensitivity to infrared light can cause color distortion in daytime images.

What is an IR-cut filter?

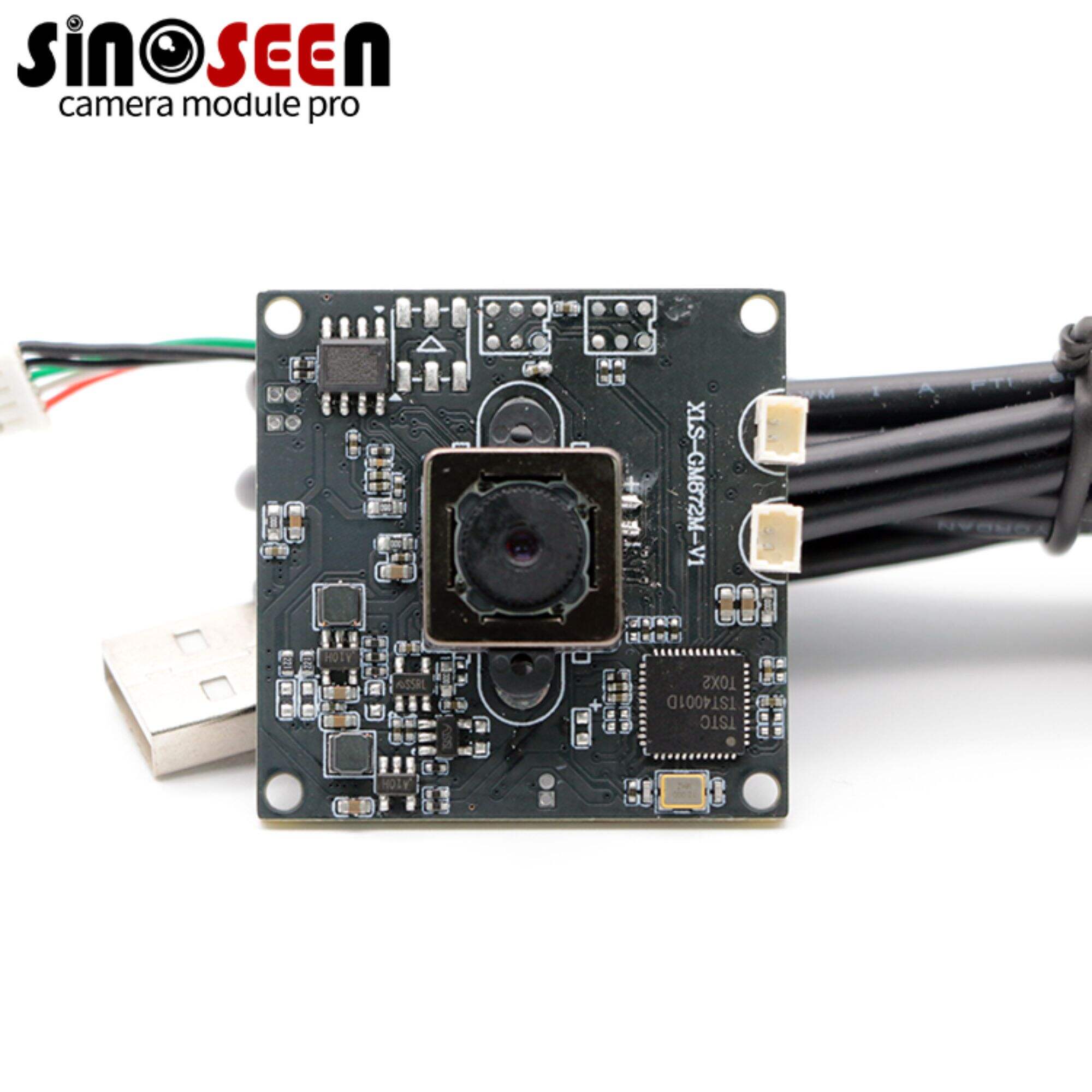

An IR-cut filter, also known as an infrared cut filter, is an optical filter installed between the camera lens and the image sensor. It allows visible light to pass while blocking infrared light from reaching the sensor.

This filter is almost standard in modern camera modules. It is typically a tiny piece of glass or coating with a specialized thin-film coating technology, and its presence determines the camera's imaging characteristics.

How does an IR-cut filter work?

The working principle of an IR-cut filter relies primarily on its unique thin-film coating. This coating is typically a dielectric film that selectively reflects or transmits specific wavelengths of light by exploiting the interference effect of light.

In daytime mode, the IR-cut filter is placed in front of the sensor, reflecting infrared light while allowing visible light to pass. At night or in low-light conditions, it is moved out of the way, allowing infrared light to enter the sensor, thus complementing the IR illumination for night vision.

The mechanical switching of this filter between day and night is key to the 24/7 monitoring capabilities of modern security cameras.

The Relationship Between IR Filter Cameras and IR Cut Filters

In bright daylight, IR filter cameras rely on an IR cut filter to function properly. Without this filter, the image sensor captures both visible and infrared light.

Because the sensor is more sensitive to infrared light than the human eye, this can cause an unnatural color cast in images. For example, objects that should be black may appear purple or brownish-red.

IR filter cameras block this excess infrared light, ensuring that only visible light enters the sensor, thereby reproducing true, accurate colors. This is the most basic and important function of the filter.

Three Reasons to Use an IR-Cut Filter

In embedded vision system design, IR-cut filters are typically used for the following three core reasons:

- Enabling Color Reproduction: This is the primary reason. The filter eliminates the interference of infrared light on image color, ensuring that the camera's color rendering in daylight matches what the human eye sees.

- Improving Image Clarity: Infrared light and visible light have different focal planes. Without filtering, this results in blurry images. An IR-cut filter ensures that all light is focused on the sensor, improving image clarity and sharpness.

- Meeting Day/Night Mode Switching Requirements: For security surveillance equipment that operates 24/7, IR-cut filters enable automatic switching between color mode during the day and black-and-white mode at night, making them a key component for achieving dual-mode imaging.

Their Role in IR CCTV Cameras

IR cut filters are highly valuable in IR CCTV cameras (infrared CCTV cameras). These cameras must adapt to a wide range of lighting conditions, from bright daylight to pitch black night.

During the day, the filter automatically switches into place, blocking infrared light and ensuring true color in recorded footage. When light levels are low, the system removes the infrared cut filter and activates the IR lights for security cameras, switching them to a high-sensitivity black-and-white night vision mode.

This seamless day/night transition is the key technology that enables IR CCTV cameras to achieve 24/7 surveillance and become a mainstream solution in the security industry.

IR lights for security cameras

IR lights for security cameras (infrared fill lights) and IR cut filters work closely together. The IR cut filter determines the camera's daytime imaging quality, while the IR cut filter determines its night vision capabilities.

During the day, the filter is active and the fill light is off. At night, the filter is removed and the fill light is on. Only in this way can the camera receive the infrared light from the fill light in darkness and clearly capture objects in the scene.

The precise coordination between the two is key to ensuring the camera produces high-quality images in any environment and is a core consideration in embedded vision system design.

Minolta infrared filter

Minolta infrared filters have existed since the days of film photography. These filters are primarily used for specialized photographic purposes, such as creating unique black-and-white infrared images. Unlike the automatically switching IR cut filters found in modern camera modules, these filters are typically manually attached to the lens.

Although the technologies differ, the principles are the same: controlling the amount of infrared light entering the sensor. Understanding this historical context can help us more fully appreciate the importance of infrared cut filters in the development of imaging technology.

UV IR Cut Filters

In addition to the common IR-cut filters, there are more advanced UV/IR cut filters. These filters block both ultraviolet and infrared light, providing broader-spectrum protection. For professional applications requiring extremely high image quality, such as medical imaging and scientific research, these filters effectively eliminate interference from ultraviolet and infrared light, ensuring image purity and accuracy. This is particularly important in fields that rely on precise pixel information.

Summary

IR-cut filters are an indispensable core component in modern camera modules. By optically filtering between visible and infrared light, they address the color cast problem of image sensors during daytime imaging and pave the way for infrared night vision capabilities. Understanding the principles, functions, and application scenarios of IR-cut filters is essential knowledge for every embedded vision engineer. They not only determine the color fidelity of an image but also determine the reliable operation of a security surveillance system at all times.

Muchvision's IR-cut filter solutions

Facing day and night imaging challenges in your embedded vision project design? Contact our expert team today for expert camera module selection consultation to ensure your product captures clear, realistic images in any lighting condition.

EN

EN

AR

AR

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

SR

SR

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

MS

MS

IS

IS

AZ

AZ

UR

UR

BN

BN

HA

HA

LO

LO

MR

MR

MN

MN

PA

PA

MY

MY

SD

SD