Why Choose a High-Performance Embedded Camera Module for AI Applications?

Artificial intelligence applications demand precision, speed, and reliability in their visual data acquisition systems. An embedded camera module serves as the critical foundation for AI-powered devices, from autonomous vehicles to smart manufacturing systems. These compact yet sophisticated imaging solutions integrate seamlessly into diverse hardware platforms while delivering exceptional performance across challenging operational environments. The selection of an appropriate embedded camera module significantly impacts the overall effectiveness of AI vision systems, making it essential to understand the key factors that differentiate high-performance modules from standard alternatives.

Modern AI applications require camera modules that can process visual data with unprecedented accuracy and speed. An embedded camera module designed for AI applications must balance multiple performance parameters including sensor quality, processing capabilities, and power efficiency. These modules integrate advanced image sensors with sophisticated signal processing algorithms to deliver crisp, detailed imagery that enables accurate AI inference. The embedded nature of these solutions allows for direct integration into host systems, reducing latency and improving overall system responsiveness.

Technical Specifications That Define Performance

Sensor Technology and Resolution Requirements

The heart of any embedded camera module lies in its image sensor technology, which determines the quality and characteristics of captured visual data. High-performance modules typically incorporate advanced CMOS sensors that offer superior light sensitivity, dynamic range, and noise reduction capabilities. Resolution requirements vary significantly across AI applications, with some demanding ultra-high definition for detailed analysis while others prioritize frame rate over pixel count. An embedded camera module for AI applications must strike an optimal balance between resolution, frame rate, and power consumption to meet specific use case requirements.

Modern sensor technologies enable embedded camera modules to capture high-quality imagery under diverse lighting conditions. Advanced pixel architectures, including backside-illuminated sensors and global shutter designs, enhance light gathering efficiency and reduce motion blur in dynamic environments. These technological improvements are particularly crucial for AI applications that operate in challenging conditions, such as outdoor surveillance systems or industrial quality control environments where lighting conditions can vary dramatically throughout operational cycles.

Image Processing Capabilities and AI Optimization

Contemporary embedded camera modules incorporate dedicated image signal processors that optimize raw sensor data for AI algorithms. These processors handle essential functions including noise reduction, color correction, and dynamic range enhancement, ensuring that AI models receive high-quality input data for accurate inference. Advanced modules may include hardware-accelerated features specifically designed to support common AI preprocessing tasks, reducing computational load on the host system and improving overall performance efficiency.

The integration of AI-specific optimization features within an embedded camera module can significantly enhance system performance. Edge computing capabilities, built-in neural processing units, and optimized data pathways enable real-time AI inference directly within the camera module itself. This approach reduces bandwidth requirements, minimizes latency, and enables distributed intelligence across networked camera systems, making it particularly valuable for applications requiring immediate response times or operating in bandwidth-constrained environments.

Integration Advantages for AI Systems

Seamless Hardware Integration

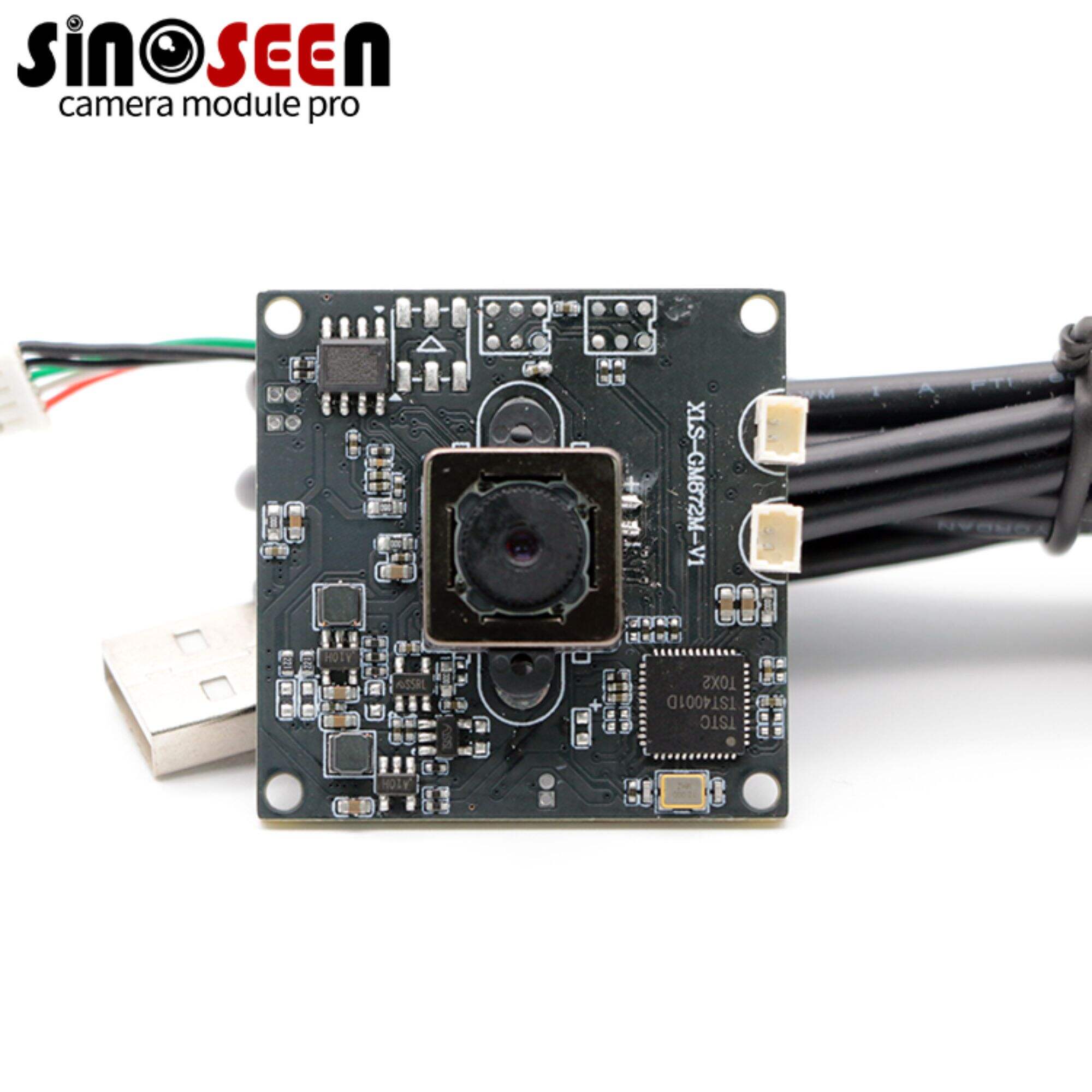

An embedded camera module offers significant advantages in terms of system integration compared to discrete camera solutions. These modules are designed with standardized interfaces that simplify connection to host processors and development boards. Common interface standards such as MIPI CSI, USB, and Ethernet enable straightforward integration across diverse hardware platforms while maintaining high-speed data transmission capabilities essential for AI applications requiring real-time processing.

The compact form factor of embedded camera modules enables integration into space-constrained devices where traditional camera systems would be impractical. This miniaturization capability is particularly valuable for mobile AI applications, robotics, and IoT devices where size and weight constraints are critical design considerations. Despite their compact size, high-performance embedded camera modules maintain professional-grade imaging capabilities suitable for demanding AI applications.

Power Efficiency and Thermal Management

Power consumption represents a critical consideration for embedded camera modules deployed in battery-powered or energy-sensitive AI applications. Advanced modules incorporate sophisticated power management features including dynamic voltage scaling, selective component activation, and intelligent sleep modes that minimize energy consumption during inactive periods. These power optimization strategies are essential for extending operational lifetime in portable devices and reducing cooling requirements in fixed installations.

Thermal management becomes increasingly important as embedded camera modules incorporate more sophisticated processing capabilities. High-performance modules are designed with effective heat dissipation mechanisms that maintain stable operation under continuous use conditions. Proper thermal design ensures consistent image quality and prevents performance degradation that could impact AI algorithm accuracy, making thermal considerations a key factor in module selection for demanding applications.

Application-Specific Performance Considerations

Computer Vision and Object Detection

Computer vision applications place specific demands on embedded camera modules, particularly regarding image clarity, color accuracy, and temporal consistency. Object detection algorithms require high-contrast imagery with minimal noise and distortion to achieve accurate classification and localization results. An embedded camera module optimized for computer vision applications typically incorporates advanced lens systems, precise focus mechanisms, and sophisticated image enhancement algorithms to deliver the image quality required for reliable AI performance.

Frame synchronization and timing accuracy are crucial for applications involving motion analysis or multi-camera systems. High-performance embedded camera modules provide precise timing controls and synchronization capabilities that enable coordinated capture across multiple devices. This synchronization is essential for applications such as stereo vision, panoramic imaging, and multi-perspective object tracking where temporal alignment directly impacts algorithm effectiveness.

Industrial Automation and Quality Control

Industrial applications demand embedded camera modules capable of operating reliably in harsh environments while maintaining consistent performance standards. These environments often involve extreme temperatures, vibration, dust, and electromagnetic interference that can degrade image quality or cause system failures. High-performance industrial embedded camera modules incorporate ruggedized designs, enhanced shielding, and environmental protection features that ensure continued operation under challenging conditions.

Quality control applications require exceptional image consistency and repeatability to enable accurate defect detection and measurement. An embedded camera module for industrial AI applications must provide stable color reproduction, precise geometric calibration, and minimal variation between units to ensure consistent results across production lines. Advanced calibration features and quality assurance processes during manufacturing help achieve the reliability standards required for critical industrial applications.

Selection Criteria for Optimal Performance

Performance Benchmarking and Validation

Evaluating embedded camera module performance requires comprehensive testing across multiple parameters relevant to specific AI applications. Key performance metrics include resolution accuracy, color fidelity, dynamic range, noise characteristics, and frame rate stability under various operating conditions. Standardized testing protocols help ensure objective comparison between different modules and validate performance claims against real-world application requirements.

Long-term stability testing is particularly important for embedded camera modules intended for continuous operation in AI systems. Performance validation should include extended operation cycles, temperature cycling, and stress testing to identify potential degradation patterns or failure modes. This comprehensive validation approach helps ensure that selected modules will maintain performance standards throughout their operational lifetime, reducing maintenance requirements and system downtime.

Compatibility and Future-Proofing

Selecting an embedded camera module requires careful consideration of compatibility with existing and planned AI frameworks, development tools, and system architectures. Modern modules should provide comprehensive software development kits, driver support for popular operating systems, and compatibility with leading AI development platforms. This software ecosystem support significantly reduces integration time and enables developers to focus on AI algorithm development rather than low-level camera interface programming.

Future-proofing considerations include upgrade pathways, evolving interface standards, and anticipated AI algorithm requirements. An embedded camera module with flexible configuration options, expandable memory interfaces, and upgradeable firmware provides better long-term value and adaptability to changing application requirements. Forward compatibility with emerging AI standards and protocols helps protect investment in camera infrastructure as AI technologies continue to evolve.

Cost-Effectiveness and Return on Investment

Total Cost of Ownership Analysis

While initial purchase price represents an important consideration, the total cost of ownership for an embedded camera module extends far beyond the upfront investment. Factors including integration complexity, development time, maintenance requirements, and operational efficiency significantly impact long-term costs. High-performance modules with comprehensive development support and proven reliability often provide better overall value despite higher initial costs.

Energy efficiency considerations become particularly important for large-scale deployments where operational costs accumulate over time. An embedded camera module with superior power management capabilities can generate significant savings through reduced energy consumption and cooling requirements. These operational savings, combined with improved system reliability and reduced maintenance needs, often justify the premium associated with high-performance camera modules.

Performance Impact on AI Algorithm Effectiveness

The quality of visual input data directly impacts AI algorithm performance, with higher-quality imagery typically enabling more accurate and reliable results. An embedded camera module that delivers superior image quality can improve AI model accuracy, reduce false positives, and enable more sophisticated analysis capabilities. These performance improvements translate into tangible business value through improved operational efficiency, reduced error rates, and enhanced customer satisfaction.

Investment in high-performance embedded camera modules often enables the deployment of more advanced AI algorithms that would be impractical with lower-quality imaging systems. This capability expansion can unlock new application possibilities and provide competitive advantages through enhanced functionality and performance. The ability to leverage cutting-edge AI techniques often justifies the additional investment in premium camera module technology.

FAQ

What makes an embedded camera module suitable for AI applications compared to standard cameras?

An embedded camera module designed for AI applications incorporates specialized features including optimized image signal processing, AI-friendly data formats, low-latency interfaces, and enhanced computational capabilities. These modules are specifically engineered to provide consistent, high-quality visual data that AI algorithms require for accurate inference, while standard cameras may lack the precision, timing accuracy, and integration features necessary for demanding AI applications.

How does sensor technology impact the performance of embedded camera modules in AI systems?

Sensor technology directly influences image quality, light sensitivity, and processing speed in embedded camera modules. Advanced CMOS sensors with features like global shutters, high dynamic range, and low noise characteristics enable AI systems to operate effectively across diverse lighting conditions and capture fast-moving objects without motion blur. The sensor's architectural design and manufacturing quality determine the module's ability to provide consistent, reliable visual data essential for AI algorithm performance.

What interface options are most important for embedded camera module integration?

The most critical interface options for embedded camera modules include MIPI CSI for high-speed, low-power mobile applications, USB for versatile connectivity, and Ethernet for network-based systems. The choice depends on bandwidth requirements, power constraints, and system architecture. High-performance AI applications typically benefit from interfaces that provide sufficient bandwidth for high-resolution, high-frame-rate video streams while maintaining low latency for real-time processing requirements.

How do environmental factors affect embedded camera module selection for industrial AI applications?

Environmental factors including temperature extremes, humidity, vibration, and electromagnetic interference significantly impact embedded camera module performance in industrial settings. Modules designed for industrial AI applications must incorporate ruggedized housings, enhanced sealing, temperature compensation, and electromagnetic shielding to maintain consistent operation. These environmental considerations often require specialized variants of embedded camera modules with additional protection features and validated performance across extended operating ranges.

EN

EN

AR

AR

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

SR

SR

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

MS

MS

IS

IS

AZ

AZ

UR

UR

BN

BN

HA

HA

LO

LO

MR

MR

MN

MN

PA

PA

MY

MY

SD

SD