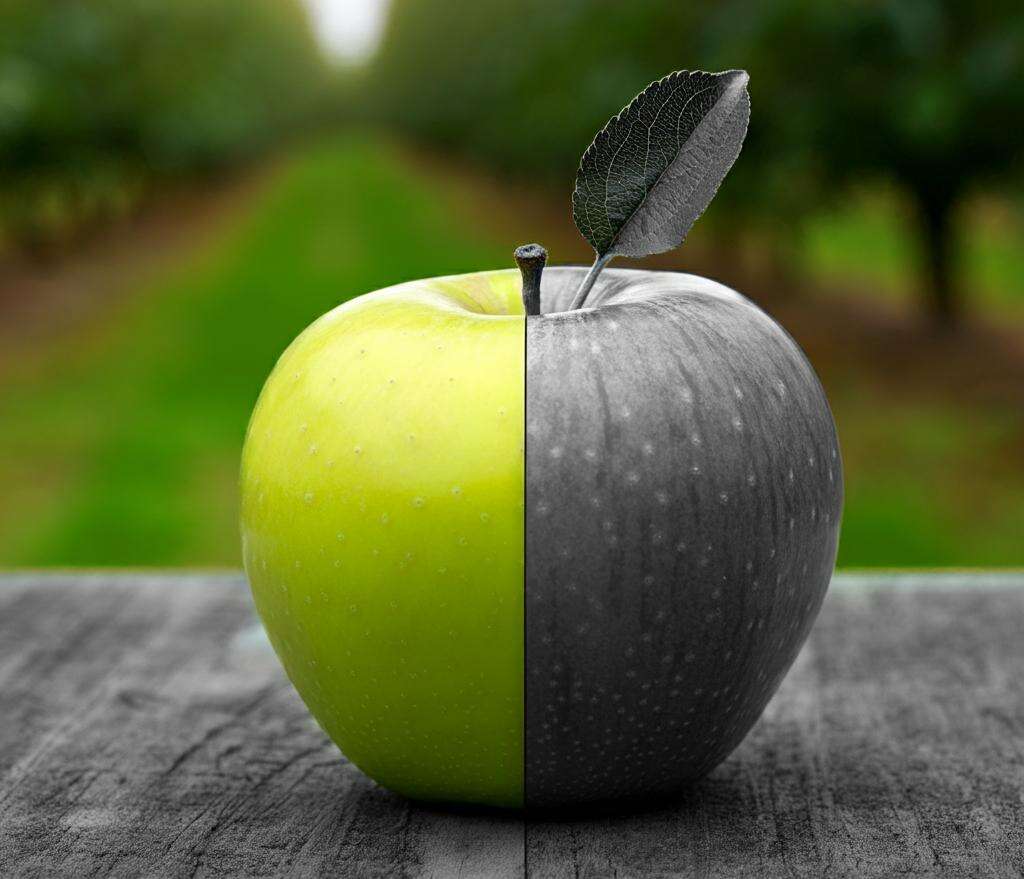

Monochrome vs. Color Camera Modules: Why Monochrome Camera Modules are Better in Embedded Vision?

In the world of embedded vision, choosing a camera is about more than just color photography. For engineers striving for ultimate performance, every technical detail can impact the success or failure of the final product. Black and white cameras, or "monochrome cameras," are quietly becoming the preferred choice in certain applications.

From the perspective of a camera module expert, this article will provide an in-depth analysis of the core differences between monochrome and color cameras and explain why monochrome cameras are the superior choice for embedded vision. We will provide a comprehensive reference guide covering technical principles, performance specifications, and practical applications.

What is a Color Camera?

Color cameras are the most common type of camera in our daily lives. Whether it's a smartphone or a DSLR, they are dedicated to capturing and reproducing real-world colors. Their core goal is to provide accurate color information for each pixel.

These cameras capture light using a photosensitive element (such as a CMOS or CCD). However, to distinguish between different wavelengths of light, they rely on a specialized component—the color filter array (CFA).

Color Filter Array and Bayer Pattern

The color filter array (CFA) is the key difference between color cameras and monochrome cameras. It is a matrix of tiny filters covering each pixel, each filter allowing only specific wavelengths of light to pass through. The most common CFA layout is the well-known Bayer pattern.

The Bayer pattern arranges pixels in a 2x2 matrix, consisting of one red filter (R), one blue filter (B), and two green filters (G). This design mimics the human eye's high sensitivity to green and is intended to improve image quality, but it also presents unique challenges.

What is Demosaicing?

Due to the Bayer pattern, each pixel actually captures only one of the three primary colors: red, green, and blue. For example, a red pixel only records the intensity of red light, while information about blue and green is missing. To produce a full-color image, the camera must perform a complex process called demosaicing.

Demosaicing algorithms analyze the color information of neighboring pixels to infer the missing color data. While this process can synthesize a full-color image, it is essentially an interpolation operation and can introduce image noise or artifacts, especially in areas with rich edges.

What is a Monochrome Camera?

Unlike color cameras, monochrome cameras do not use any color filter arrays. Their sensors are directly exposed to light, allowing each pixel to capture all wavelengths of incoming light and convert them into brightness information. This is why they produce pure black and white, or grayscale, images.

This filter-free design allows monochrome cameras to maximize the use of incoming light, fundamentally improving their photosensitivity. They eliminate the need for complex demosaicing processes, giving them certain advantages over color cameras.

Why are monochrome cameras better than color cameras in embedded vision?

In embedded vision applications, camera selection is often driven by performance rather than subjective color aesthetics. For most applications, such as industrial inspection, security monitoring, and autonomous driving, color information isn't essential. In this context, monochrome cameras, due to their unique technical advantages, are a superior solution over color cameras.

First, monochrome cameras offer higher light sensitivity. Without the obstruction of a color filter array, the sensor receives nearly all incoming light, enabling them to capture clear, detailed images even in low-light conditions. This is crucial for nighttime security monitoring or quality inspection in dimly lit corners of a factory.

Second, monochrome cameras offer faster algorithm processing. Color cameras require complex de-mosaicing and color correction, computational tasks that consume significant processing resources and time. Monochrome cameras, however, eliminate these steps, allowing image data to be directly output, significantly improving frame rates and processing efficiency.

Finally, monochrome cameras offer advantages in resolution and image detail. On sensors with the same number of pixels, color cameras have lower effective resolution than monochrome cameras because they need to interpolate to synthesize colors. Each pixel in a monochrome camera records complete brightness information, providing sharper and more realistic image details.

Differences between monochrome digital cameras and color cameras

To more intuitively understand the differences between the two, we can compare them along several key dimensions:

Image Quality: Monochrome cameras provide clearer, sharper images in low-light environments, with greater detail. While color cameras can capture color, their images may appear blurry, noisy, and lose detail in the same conditions.

Light Sensitivity: Because they lack a filter array, monochrome cameras are over three times more sensitive to light than color cameras. This means that in low light conditions, monochrome cameras can achieve high-quality images with lower gain or shorter exposure times, reducing noise and motion blur.

Resolution: Given the same hardware specifications, monochrome cameras have higher "effective resolution" because each pixel represents a single brightness value, while color cameras require multiple pixels to "infer" a single color pixel value.

Algorithm Complexity: The image processing algorithms used by monochrome cameras are simple and efficient, requiring no demosaicing. Color cameras require additional algorithms to process colors, which not only increases the burden on the processor but also may affect real-time performance.

Embedded Vision Applications of Color Cameras

Despite the superior performance of monochrome cameras, color cameras remain indispensable in certain specific embedded vision applications. Their core value lies in their strong reliance on color information. For objects that cannot be distinguished by brightness or texture, color becomes the most critical identification feature.

Industrial Quality Inspection

In the manufacturing industry, many product quality inspection criteria are closely related to color. For example, on electronic component production lines, the color rings on resistors must be identified to determine their resistance value. In printed product quality control, cameras check whether product packaging meets color standards and whether there is ink spillage or color deviation. Furthermore, in the food and beverage industry, color inspection of product labels and bottle caps is crucial for ensuring product consistency and brand compliance.

Medical Image Analysis

The medical field is another important area where color cameras are proving useful. For example, in skin disease screening, doctors can analyze the color, edges, and symmetry of moles to aid diagnosis, which requires high-precision color images. In pathology slide analysis, tissue samples are often stained to highlight cell structure and pathological features. Color cameras are responsible for capturing these subtle color variations, assisting pathologists in making diagnoses.

Produce Sorting and Harvesting

In agricultural automation, color is a key indicator of produce ripeness. For example, on a fruit sorting line, color cameras can sort apples into different grades based on the depth of red or the yellowness of bananas. Similarly, in intelligent harvesting robots, color differences help them accurately identify and locate ripe fruit, avoiding accidentally damaging unripe fruit or leaves.

Retail and Smart Shelf Management

With the development of new retail technologies, smart shelf management systems are emerging. These systems use color cameras to monitor products on shelves. By recognizing the unique colors and patterns on product packaging, the systems can determine in real time whether inventory is sufficient and correctly positioned, and promptly issue instructions to staff for restocking or adjustments. This is crucial for maintaining clean shelves and improving the customer experience.

Conclusion: The Advantages of Monochrome Digital Cameras

In summary, while color cameras dominate the mass consumer market with their rich color rendering, monochrome cameras offer even greater advantages in the performance-demanding embedded vision field.

Their superior low-light performance, faster processing speeds, higher effective resolution, and simplified algorithm workflows make them the preferred choice for applications such as industrial inspection, security monitoring, and automated driver assistance systems. Choosing a monochrome camera means you're choosing higher efficiency, greater robustness, and more accurate image data.

Sinoseen empowers your color and black-and-white vision solutions.

If you're facing challenges selecting a camera for your embedded vision project, or would like to learn more about our digital camera solutions for black-and-white photography, please don't hesitate to contact us. With over 15 years of experience providing OEM camera solutions, we offer a variety of black-and-white camera configurations and specifications to meet your specific needs. Let's work together to find the perfect vision solution for your project.

EN

EN

AR

AR

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

SR

SR

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

MS

MS

IS

IS

AZ

AZ

UR

UR

BN

BN

HA

HA

LO

LO

MR

MR

MN

MN

PA

PA

MY

MY

SD

SD