מהן היתרונות המרכזיים בשימוש במודולי מצלמה של יצרנים מקוריים באלקטרוניקה לצרכן?

מצוינות בהתאמה אישית ואינטגרציה

מפרט מותאם אישית להבחנה של המותג

התאמה אישית של מצלמת OEM מודולים הוא כלי אסטרטגי שמעודד את זהות המותג ויכולתו למכור. מפרטיזציה ייעודית מאפשרת לחברות לעמוד בולט בתחרות ובשواقים קשים ול đápול על דרישות הצרכן הייחודיות. לדוגמה, התאמה של אפשרויות עדשות למצלמות מודולריות יכולה להשפיע משמעותית על הדרך בה נ percipיפים ויישומים של המוצרים, וכך ליושר עם מטרות ספציפיות של המותג. מספר חברות צברו צמיחה משמעותית בעזרת ייחודי כזה. לפי מחקרים בתעשייה, מותגים אשר מאמצים מצלמות מודולריות מותאמות אישית, כמו אלו המשנות את ה firmware לצורך דרישות ספציפיות, מדלגים על עלייה של עד 30% בשיתוף השוק עקב סיפוק לקוחות מוגזם. גישה זו מספקת לא רק יתרון טכנולוגי אלא גם בונה ערך מתמשך למותג.

אינטגרציה חלקה של חומרה בין סוגי מכשירים

אינטגרציה חלקה של חומרה בין מגוון סוגי מכשירים, כולל טלפונים חכמים, טאבלטים ושעונים חכמים, היא קריטית למוצרים טכנולוגיים מודרניים. מודולי מצלמה של יצרנים מקוריים (OEM) תורמים משמעותית לאינטגרציה זו על ידי ביטוח תאימות ומשיכת חוויית המשתמש. לדוגמה, מודולי מצלמה התומכים בפורמטים מרובים של וידאו מאפשרים פעולה חלקה בין פלטפורמות שונות, ובכך משפרים את שביעות הרצון של המשתמש. מחקר מצביע על כך שמכשירים עם מודולי מצלמה מאופטימליים ניצבים באחוזי אprobציה גבוהים יותר מצד הצרכנים. סקר הראה כי 40% מהלקוחות מאמינים שהתאימות הטכנית של המוצר היא גורם קובע בהחלטתם לרכישה. נתוני המחקר מדגישים עד כמה מאמצים יציבים באינטגרציה יכולים להניע הצלחה שוקית ולשפר את השימושיות של מכשירי צריכה.

ארכיטקטורה מודולרית לעיצוב גמיש

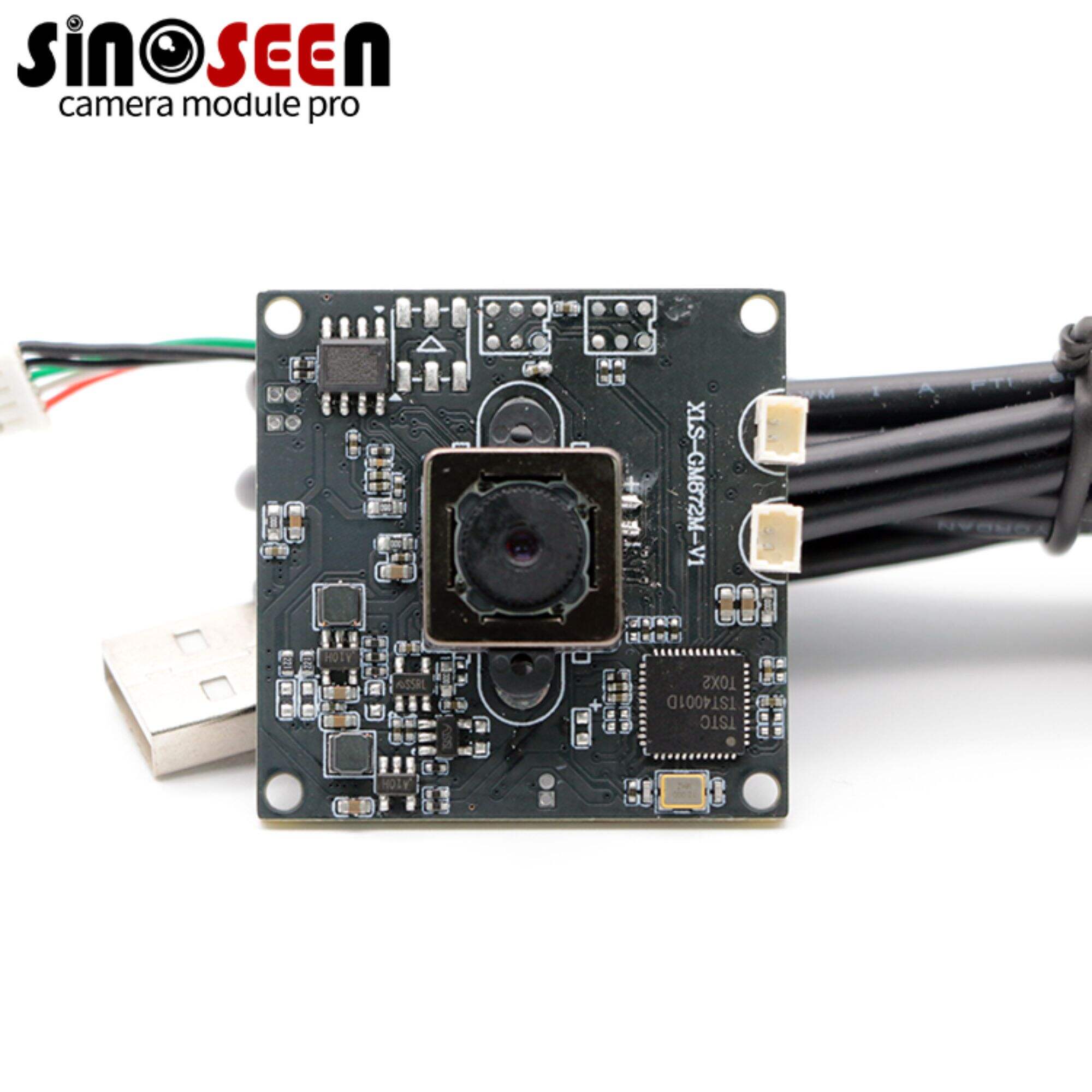

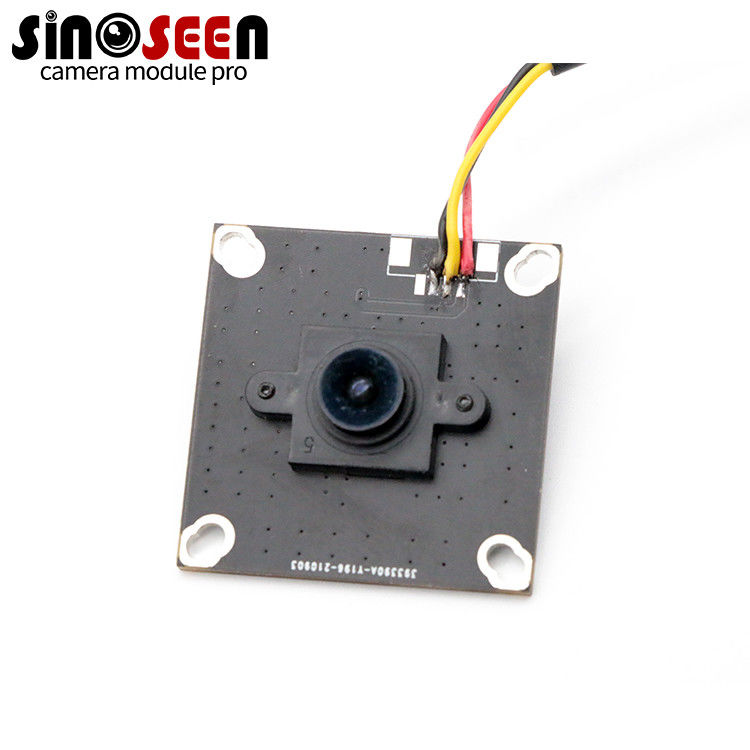

עיצוב ארכיטקטורה מודולרית בעיצוב מODULE מצלמה של היצרן מציע יתרונות משמעותיים במונחי גמישות בעיצוב וחדשנות. גישה זו מאפשרת התאמה פשוטה ושדרוג מהיר, מה שעושה אותה למאוד חשובה לצורך התאמה לצרכים משתנים של הצרכנים. חברות גדולות בתחום, כמו סינוסין, הצליחו nhờ בשימוש בעיצובים מודולריים כדי לשכלל את קווי המוצרים שלהן. מומחים sectorials תומכים בעיצובים מודולריים, עם דגש על סטנדרטים שקשורים להתאמה וגיוון חדשני. ארכיטקטורת מודולרית לא רק מקלה על ייצור זול יותר, אלא גם תומכת ביכולת להרחיב בעתיד, ומספקת מודל צמיחה בר-קיימא לחברות המשקיעות@Module מצלמות של יצרן. ככל שיותר מותגים אומצים את פילוסופיית העיצוב הזו, הם יכולים לשפר את מעמדתם בשוק והתגובה לדרישות המשתמש.

פתרונות ייצור המוניים זולים

ייצור מואמט לייצור כמויות גדולות

תהליכי ייצור מותאמים תורמים משמעותית להגדלת הייצור תוך שמירה על האיכות. על ידי יישום טכנולוגיות מתקדמות וتقنيות ייצור חסר-בזבוז, חברות יכולות להשיג ייצור בכמויות גדולות מבלי לפגוע באיכותם של מודולי המצלמה המקוריות. לפי דוחות תעשייתיים, חברות המשתמשות באסטרטגיות ייצור מותאמות צפינו הפחתת עלויות בשיעור של עד 15%. בנוסף, אסטרטגיות לייצור המוני משפיעות על המחירים, מאפשרות לחברה להציע דמי מנוי תחרותיים, מה שמעודד את הדרישה בשוק ומורחב את בסיס הצרכנים.

יתרונות קנייה מרובת חומרים

איסוף חומרים בכמויות תורם לחיסכון משמעותי בעלות ומשפר את האמינות בתוך שרשרת האספקלה. על ידי הקמת יחסים ארוכי טווח עם ספקים, חברות יכולות להבטיח מחירים נמוכים יותר לחומרים, ולהבטיח זרם אספקלה רציף ואמין. לרוב, אסטרטגיות איסוף מוצלחות כוללות שותפויות שמגבשות אמון ויתרונות הדדיים. לדוגמה, לאחר המעבר לאיסוף בכמויות, דיווחו מספר תחומים על ירידה של למעלה מ-20% בעלויות החומרים. חיסכונות אלו משפיעים ישירות על העלות הכוללת של הייצור, ומעודדות רווחיות ותחרותיות בשוק למצלמות מודולריות (OEM).

הפחתת עלויות פיתוח באמצעות תקינה

סטנדרטיזציה בתהליכי ייצור היא כלי מרכזי בהפחתת עלויות הפיתוח ובהעצמת יעילות תהליכי העבודה. באמצעות אימוץּן של פרקטיקות סטנדרטיות, חברות מפשטות את הפעילות שלהן, ומפחיתות מורכבות וצריכת זמן. הגישה הזו הביאה להצלת עלויות משמעותית בחברות רבות, כפי שמוצג במגוון רחב של מקרי דוגמה מהתעשייה. מומחה בתחום ציין כי סטנדרטיזציה יוצרת סביבה אחידה, ומאפשרת התאמה מהירה לשינויים בשוק ולפיתוחים טכנולוגיים. עבור מודולי מצלמות OEM, משמעות הדבר היא הישארות בפרצוף המתקדם של החדשנות, תוך שמירה על עלויות בפיקוד, מה שמוביל בסופו של דבר לתועלת רבה לייצרנים ו לצרכנים כאחד.

איכות איכות וביצוע ללא פשרות

פרוטוקולי בדיקה קפדניים

שמירה על אמינות המוצר היא קריטית ביצור מודולי מצלמה של יצרני ציוד מקורי (OEM), ולכן מומצאים פרוטוקולים קפדניים לבדיקה. שיטות אלה כוללות בדיקות סביבתיות, המש뮬ות תנאים קשים כדי להבטיח עמידות, ובדיקות ביצועים במטרה להעריך את איכות התמונה והפונקציונליות בתנאי תאורה שונים. תוצאות מעבדה עצמאיות מאמתות באופן עקבי את רמת הגבוהה של פרוטוקולי הבדיקה הללו, ומחזקות את אימות האיכות של המוצרים. עמידה בסטנדרטים תעשייתיים, כגון אלו שמוגדרים על ידי המוסד הבינלאומי לאלקטרוטכника (IEC), מבטיחה שמודולי המצלמה של יצרני ציוד מקורי עומדים בדרישות הבדיקה הנדרשות, וכך מחזקים את אמינותם בשוק.

הסכמה לסטנדרטים בינלאומיים

המימוש של סטנדרטים בינלאומיים באיכות ובבטיחות הוא חובה עבור מודולי מצלמה של יצרני ציוד מקורי (OEM) שרוצים לקבל הכרה בשוק העולמי. עמידה בדרישות אלו לא רק שמבטיחה את הבטחה של המוצר אלא גם מחזקת את האמון של הצרכנים. אישורים כמו ISO 9001 למערכת ניהול איכות והסימן CE לאימות התאמה לשוק האירופאי הם חשובים במיוחד למודולי מצלמות של יצרני ציוד מקורי. נתונים סטטיסטיים מצביעים על כך שלמוצרים עם אישורים אלו קיים קבלת פנים גבוהה יותר בהשוואה למוצרים שאינם עומדים בדרישות, מה שממחיש את חשיבות הדבקות בסטנדרטים בינלאומיים. עמידה בדרישות אלו מסמלת מחויבות להבטחת איכות ופועלת לקידום כניסה חלקה לשוקים תחרותיים ברחבי העולם.

הבטחת קריאביליות לטווח ארוך

אמינות ארוכת טווח במוצרי אלקטרוניקה לצרכן היא חיונית לשמירה על שביעות רצון הלקוחות ופחת הוצאות הקשורות לפיחותים במכשור. מודולי מצלמה של יצרנים מקוריים (OEM) ממקדים בביטוח איכות כדי להבטיח תפקוד ארוך טווח, כפי שמוצג בתיקי המקרים שמציגים מוצרים שגאו בעקבות סטנדרטים קפדניים לאיכות. לדוגמה, מודולים שעברו מבחני מחזור חיים נרחבים הדגימו אחוזי כשל נמוכים יותר וביצועים מתמשכים לאורך זמן. מומחים בתחום מדגישים את היתרונות בעתיד משקיעה באיכות, שכן הדבר אינו רק מגביר את אמון הציבור במוצר אלא גם מחזק את המוניטין של המותג, ומבטיח הצלחה מתמשכת בתעשייה האלקטרונית התחרותית.

הפעלת תכונות מתקדמות לצרכן

enfוקוס אוטומטי וייצוב תמונה אופטי

מיקוד אוטומטי וייצוב תמונה אופטי הם תכונות חיוניות המשפרות את חוויית המשתמש בטכנולוגיות מצלמה מודרניות. התקדמויות אלו מאפשרות למצלמות להתאים אוטומטית את המיקוד ולייצב תמונות בעת צילום תנועה, וכתוצאה מכך תמונות ברורות ומפורטות יותר. פריצות דרך טכנולוגיות, במיוחד במודולי מצלמות OEM, הפכו תכונות אלו לנגישות יותר לצרכנים. על פי סקרים אחרונים, חלה עלייה משמעותית בשביעות רצון המשתמשים המיוחסת לשיפור בהירות התמונה ויציבותה, דבר המדגיש את חשיבותן של תכונות אלו בצילום יומיומי.

טכנולוגיה Technology.AI-Powered פנימית זיהוי פנים

השלבת טכנולוגיית זיהוי פנים המונעת ב-AI הופכת את הצילום עבור צרכנים, כאשר היא מציעה חוויות צילום מותאמות אישית ויעילות יותר. הטכנולוגיה משתמשת באלגוריתמים מתקדמים לזיהוי ואימות של פנים בתמונות, ומסדרת אוטומטית את התמונות על פי האנשים בהן. יישומים אלו של الذكاء המלאכותי מספקים נוחות, במיוחד במכשירי טלפון וביטחון. מחקר מצביע על מגמה משמעותית של גידול בביקוש לתכונות AI, כאשר תחזיות שוק מראות עלייה מתמדדת העדפת הצרכנים למוצרים מצוידים ביכולות זיהוי פנים. הדבר מדגיש את ההשפעה של الذكاء המלאכותי בעיצוב עתיד טכנולוגיות הדימוי.

שיפורים בביצועים באור חלש

שיפורים בביצועים בתנאי תאורה נמוכה במודולי מצלמה של היצרנים הפכו להיות חשובים יותר ויותר למשתמשים שצולמים בתנאים קשים של תאורה. שיפורים טכנולוגיים אלו, הכוללים שילוב של חיישנים ומסננים מיוחדים, מאפשרים ש Verbesserung der Leistung bei schlechten Lichtverhältnissen in OEM-Kameramodulen ist für Benutzer immer wichtiger geworden, die häufig unter schwierigen Lichtbedingungen Fotos aufnehmen. Zu diesen technischen Verbesserungen gehören die Integration spezialisierter Sensoren und Filter, die eine bessere Bildqualität in dunkel beleuchteten Umgebungen ermöglichen. Solche Verbesserungen begegnen den Bedürfnissen der Verbraucher, da immer mehr Menschen Kameras suchen, die klare Bilder bei Dämmerung, Morgengrauen oder in Innenräumen liefern können. Aktuelle Statistiken zeigen eine zunehmende Nachfrage nach Lösungen für Fotografie bei schwachem Licht, da Benutzer Vielseitigkeit und Zuverlässigkeit bei der Wahl ihrer Kameras bevorzugen, was den Weg für weitere innovative Entwicklungen auf diesem Gebiet ebnet.

יתרונות שותפות אסטרטגית

תמיכה טכנית ארוכת טווח ואספקה

תמיכה טכנית ואספקה ארוכות טווח הן מרכיבים חיוניים בשותפויות אסטרטגיות במגזר ה-B2B. תמיכה טכנית מבטיחה שכל בעיה שמתעוררת לאחר הרכישה תיפתר במהירות, תוך שמירה על פעילות חלקה עבור עסקים. שותפויות אסטרטגיות מציעות יציבות, שכן חברות המקיימות בריתות חזקות יכולות למנף תמיכה כדי להאריך את מחזור חיי המוצר, להפחית את זמן ההשבתה ולשפר את היעילות. לדוגמה, שותפויות מתמשכות בין יצרני ציוד מקורי (OEM) של מודולי מצלמה ללקוחותיהם מובילות לעתים קרובות לתפעול חלק יותר, מה שמבטיח שמערכות המצלמה יישארו מעודכנות ופונקציונליות לאורך זמן. על פי נתוני תעשייה עדכניים, עסקים המעדיפים שותפויות ארוכות טווח חווים ירידה משמעותית בהפרעות תפעוליות, דבר המדגיש את חשיבות התמיכה המתמשכת.

חדשנות שיתופית לטכנולוגיות העתיד

חדשנות שיתופית בין יצרנים לספקים היא כוח מניע מאחורי התקדמות טכנולוגית. סינרגיה זו מאפשרת פיתוח של פתרונות מתקדמים המותאמים לצרכים עולים בשוק. למשל, מספר מודולי מצלמה מהפוניים צמחו משותפויות בין יצרני ציוד מקוריים (OEM) וספקים טכנולוגיים, מה שממחיש את הערך שבשיתוף פעולה. מומחה בתחום ציין כי שותפויות יוצרות סביבה שבה מומחיות מגוונת מתvergence ליצירת טכנולוגיות ייחודיות. ככל שאנו מתקדמים לעבר מכשירים מחוברים יותר, הצורך בחדשנות שיתופית רק גדל, ומבטיח שהמגזר הטכנולוגי ישמר את מקומו בanguard של החדשנות.

שירותי פיתוח פירמה מותאמת אישית

פיתוח פירמה מותאמת ממלא תפקיד מרכזי בשיפור השימושיות והביצועים של מודולי מצלמה של יצרנים מקוריים (OEM). על ידי התאמת התוכנה לצרכים ספציפיים, חברות יכולות לפתוח את הפוטנציאל המלא של ההשקעות הטכנולוגיות שלהן. חברות רבות דיווחו על הצלחות משמעותיות, כמו שיפור ביעילות המערכת ובסיפוק العملاء, על ידי בחירה בפתרונות פירמה מותאמים. מחקרים מוצגים לעיתים קרובות מקרים בהם פירמה מותאמת שימשה כמנוע לשיפור תפעולתי. בנוסף, סטטיסטיקות מצביעות על כך שאחרי התאמה מותאמת, חלק מהחברות חווו שיפור של עד 40% במטריצות הביצועים, מה שממחיש את האפקט העמוק של פירמה מותאמת על תפקוד המוצר.

שאלות נפוצות

מהי חשיבות ההתאמה של מודולי המצלמה של היצרנים המקוריים (OEM)?

התאמה אישית מאפשרת לחברות להתבלט בשווקים תחרותיים ולעמוד בדרישות ספציפיות של צרכנים, ובכך לשפר את זהות המותג ואת שביעות רצון הלקוחות.

איך שילוב חלקים חומריים חלק מתורגם לצרכנים?

הוא מבטיח תאימות בין סוגי מכשירים שונים, משפר את חוויית המשתמש בכלל ואת שביעות הרצון בפלטפורמות שונות.

מדוע חשובה ארכיטקטורה מודולרית בעיצוב מודולי מצלמה של היצרן?

היא מספקת גמישות בעיצוב ומאפשרת התאמה והתאמה מחדש בקלות, כדי לענות על צרכים משתנים של הצרכנים ולשפר את המוכנות לתגובה בשוק.

איזה תפקיד משחק קנייה מרובת חומרים בתהליך הייצור?

היא מקטינה משמעותית את עלויות החומרים ומשפרת את האמינות של שרשרת האספקה, ובסופו של דבר משפיעה באופן חיובי על עלויות הייצור הכלליות.

איך משפיעה עמידה בסטנדרטים בינלאומיים על מודולי המצלמה של היצרן?

העמידה מבטיחה את הבטחת המוצר, מחזקת את אמון הצרכן ומקל על הכניסה לשווקים גלובליים תחרותיים על ידי הימצאות בדרגים המקובלים.

מוצרים מומלצים

חדשות חמות

-

סין מובילה יצרנים מודול מצלמה מכשיר כוח צילוםSinoseen

2024-03-27

-

המדריך האולטימטיבי להתאמה אישית עבור מודולים מצלמת OEM

2024-03-27

-

הבנה מעמיקה של מודולי מצלמה

2024-03-27

-

איך להפחית את רזולוציית מודול המצלמה?

2024-12-18

EN

EN

AR

AR

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

SR

SR

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

MS

MS

IS

IS

AZ

AZ

UR

UR

BN

BN

HA

HA

LO

LO

MR

MR

MN

MN

PA

PA

MY

MY

SD

SD